Products Description

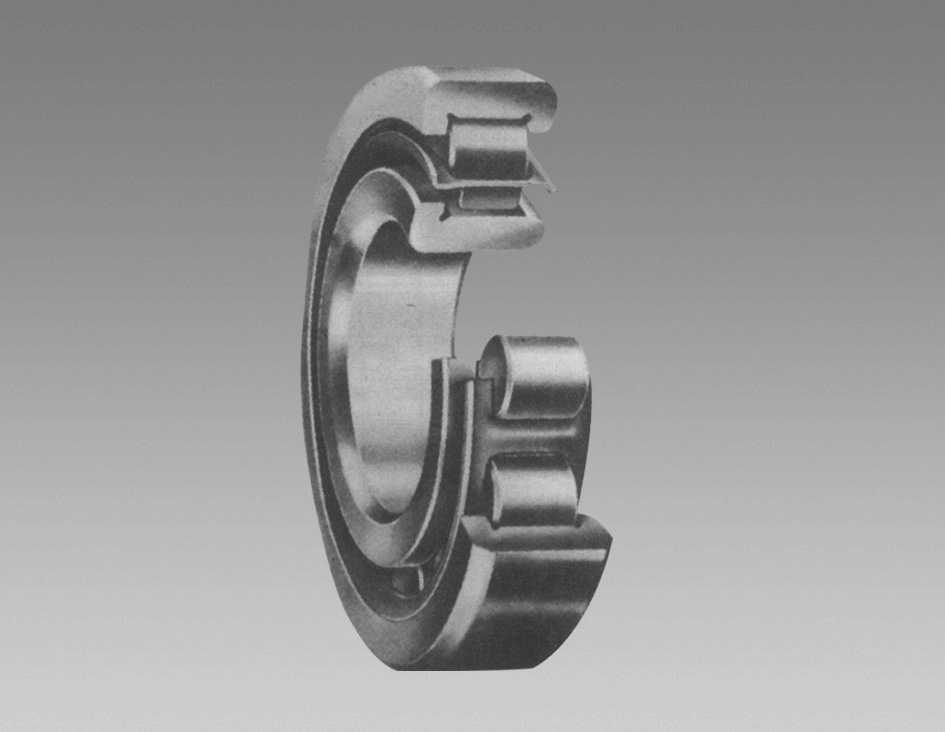

The cylindrical roller and raceway are linear contact bearings with high load capacity, mainly bearing radial loads. The friction between the rolling element and the retaining edge of the ring is small. Suitable for high-speed rotation.

According to the presence or absence of retaining edges on the ring, there are single row bearings such as NU, NJ, NUP, N, NF, and double row bearings such as NNU and NN.

This bearing is a separable structure with inner and outer rings.

A cylindrical roller bearing without a retaining edge on the inner or outer ring can be used as a free end bearing due to the relative movement of the inner and outer rings in the axial direction. A cylindrical roller bearing with a double retaining edge on one side of the inner or outer ring and a single retaining edge on the other side of the ring can withstand a certain degree of axial load in one direction.

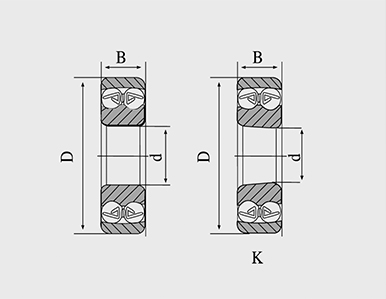

Double row cylindrical roller bearings have high rigidity against radial loads and are mainly used for machine tool spindles.

Generally, iron plate stamped cages or copper alloy car made cages are used. But there is also a portion that uses polyamide formed cages.

The bearings are designed with modifier line contact between the rollers and raceways.That can be used to carry much greater radial loads and can be allowed to rotate in much higher speeds in gereral.This type of bearings,of which the rollers and either the inner or the outer rib are hold together by the cage to form an assembly that can be removed from the other rings and also that has one or without rib,is convenient in mounting and dismounting.The bearings with inner rings or outer rings without rib are often be used for axial floating support.The bearing with inner rings and outer rings both having ribs can be used to carry a certain amount of axial loads and to restrict axial displacement of either the shaft or the housing at one side or both sides.

The double row cylindrical roller bearing(type NN3000k) with tapered bore(1:12) is of much greater radial loads carrying capacity and rigidity.Besides all are made in precision classification that is suitable for the precise spindle .

|

Bearing No. |

Dimension (mm ) |

Basic load rating(KN) |

Limiting speeds |

Mounting Dim |

Mass(kg) |

||||||||||

|

New |

Old |

d |

D |

B |

rmin |

rlmi |

Ew |

Fw |

Cr |

Cor |

Grease |

Oil |

d2 |

D2 |

|

|

N 1016/C4YA4 |

C4G2116K |

80 |

125 |

22 |

1.1 |

1 |

115.5 |

|

87.7 |

109 |

5300 |

6300 |

96.3 |

|

0.883 |

|

N 1017 M |

2117H |

85 |

130 |

22 |

1.1 |

1 |

118.5 |

|

74.3 |

95.6 |

4700 |

5600 |

100.9 |

|

1.04 |

|

N 1018 M |

2118H |

90 |

140 |

24 |

1.5 |

1.1 |

127 |

|

80.9 |

104 |

4300 |

5300 |

107.8 |

|

1.00 |

|

NU 1018 M |

32118H |

90 |

140 |

24 |

1.5 |

1.1 |

|

103 |

80.9 |

104 |

4300 |

5300 |

|

122 |

1.00 |

|

N 1019 M |

2119H |

95 |

145 |

24 |

1.5 |

1.1 |

132 |

|

84.2 |

110 |

4000 |

5000 |

112.8 |

|

1.58 |

|

NU 1019 M |

32119H |

95 |

145 |

24 |

1.5 |

1.1 |

|

108 |

84.2 |

110 |

4000 |

5000 |

|

127 |

1.58 |

|

NJ 1019 M |

42119H |

95 |

145 |

24 |

1.5 |

1.1 |

|

108 |

84.2 |

110 |

4000 |

5000 |

112.8 |

|

1.58 |

|

NU 1020 M |

32120H |

100 |

150 |

24 |

1.5 |

1.1 |

|

113 |

87.4 |

116 |

3800 |

4800 |

|

132.7 |

1.49 |

|

N 1022 M |

2122H |

110 |

170 |

28 |

2 |

1.1 |

155 |

|

128 |

166 |

3400 |

4300 |

131 |

|

2.01 |

|

NU 1022 M |

32122H |

110 |

170 |

28 |

2 |

1.1 |

|

125 |

128 |

166 |

3400 |

4300 |

|

149 |

2.30 |

|

N 1024 M |

2124H |

120 |

180 |

28 |

2 |

1.1 |

165 |

|

142 |

197 |

3200 |

4000 |

141 |

|

2.58 |

|

NU 1024 M |

32124H |

120 |

180 |

28 |

2 |

1.1 |

|

135 |

142 |

197 |

3200 |

4000 |

|

159.6 |

2.57 |

|

NJ 1024 M |

42124H |

120 |

180 |

28 |

2 |

1.1 |

|

135 |

142 |

197 |

3200 |

4000 |

141 |

159.6 |

2.30 |

|

NF 1026 M |

12126H |

130 |

200 |

33 |

2 |

1.1 |

182 |

|

165 |

224 |

2900 |

3400 |

154.1 |

175 |

4.28 |

|

N 1026 M |

2126H |

130 |

200 |

33 |

2 |

1.1 |

182 |

|

165 |

224 |

2900 |

3400 |

154.1 |

|

4.28 |

|

NU 1026 M |

32126H |

130 |

200 |

33 |

2 |

1.1 |

|

148 |

165 |

224 |

2900 |

3400 |

|

175 |

4.28 |

|

NJ 1026 M |

42126H |

130 |

200 |

33 |

2 |

1.1 |

|

148 |

165 |

224 |

2900 |

3400 |

154.1 |

175 |

4.28 |

|

NF 1028 M |

12128H |

140 |

210 |

33 |

2 |

1.1 |

|

158 |

210 |

314 |

2700 |

3200 |

166.4 |

186.6 |

4.62 |

|

N 1028 M |

2128H |

140 |

210 |

33 |

2 |

1.1 |

192 |

|

210 |

314 |

2700 |

3200 |

166.4 |

|

4.62 |

|

NU 1028 M |

32128H |

140 |

210 |

35 |

2 |

1.1 |

|

158 |

210 |

314 |

2700 |

3200 |

|

186.6 |

4.21 |

|

NJ 1028 M |

42128H |

140 |

210 |

33 |

2 |

1.1 |

|

158 |

210 |

314 |

2700 |

3200 |

166.4 |

186.6 |

4.62 |

|

NU 1030 M/YA4 |

32130H |

150 |

225 |

35 |

2.1 |

1.5 |

|

168 |

258 |

361 |

2600 |

3000 |

|

202.4 |

4.99 |

|

NJ 1030 M/YA4 |

42130H |

150 |

225 |

35 |

2.1 |

1.5 |

|

168 |

258 |

361 |

2600 |

3000 |

175 |

202.4 |

5.10 |

|

NU 1032 M |

32132H |

160 |

240 |

38 |

2.1 |

1.5 |

|

180 |

268 |

399 |

2200 |

2600 |

|

212.8 |

6.20 |

|

NJ 1032 M |

42132H |

160 |

240 |

38 |

2.1 |

1.5 |

|

180 |

268 |

399 |

2200 |

2600 |

186.6 |

212.8 |

6.34 |

|

NU 3034 M |

3032134H |

170 |

260 |

67 |

3.5 |

3.5 |

|

192 |

532 |

895 |

2200 |

2600 |

|

229 |

13.7 |

|

NU 1034 M/YA4 |

32134H |

170 |

260 |

42 |

2.1 |

2.1 |

|

192 |

304 |

437 |

2100 |

2500 |

|

229 |

8.04 |

|

NJ 1032 M/YA4 |

42134H |

170 |

260 |

42 |

2.1 |

2.1 |

|

192 |

304 |

437 |

2100 |

2500 |

200 |

229 |

8.59 |

|

NU 1036 M |

32136H |

180 |

280 |

46 |

2.1 |

2.1 |

|

205 |

358 |

519 |

1900 |

2300 |

|

245 |

10.5 |

|

N 036 M |

7002136H |

180 |

280 |

31 |

2 |

2 |

250 |

|

261 |

405 |

1600 |

2000 |

218 |

|

7.89 |

|

N 036 L |

7002136LE |

180 |

280 |

31 |

2 |

2 |

250 |

|

261 |

405 |

1600 |

2000 |

218 |

|

7.25 |

|

NU 1038 M/YA4 |

32138H |

190 |

290 |

46 |

2.1 |

2.1 |

— |

212 |

434 |

622 |

1700 |

2000 |

|

256.8 |

11.0 |

|

NF 1040 M/YA4 |

12140H |

200 |

310 |

51 |

2.1 |

2.1 |

283 |

|

446 |

656 |

1600 |

1900 |

238 |

270.1 |

14.9 |

|

N 1040 M/YA4 |

2140H |

200 |

310 |

51 |

2.1 |

2.1 |

283 |

|

446 |

656 |

1600 |

1900 |

238 |

|

14.9 |

|

NU 1040 M/YA4 |

32140H |

200 |

310 |

51 |

2.1 |

2.1 |

|

227 |

446 |

656 |

1600 |

1900 |

|

270.1 |

14.1 |

|

NJ 1040 M/YA4+HJ 1040 |

52140H |

200 |

310 |

51 |

2.1 |

2.1 |

|

227 |

1157 |

2281 |

1600 |

1900 |

|

270.1 |

15.8 |

|

NJ 1040 M/YA4 |

42140H |

200 |

310 |

51 |

2.1 |

2.1 |

|

227 |

446 |

656 |

1600 |

1900 |

238 |

270.1 |

14.4 |

|

NU 1044 M |

32144H |

220 |

340 |

56 |

3 |

3 |

|

250 |

588 |

922 |

1400 |

1700 |

|

299.2 |

19.0 |

|

NU 1044 Q4/S0 |

32144QT |

220 |

340 |

56 |

3 |

3 |

|

250 |

588 |

922 |

1400 |

1700 |

|

299.2 |

19.5 |

|

NJ 1044 M |

42144H |

220 |

340 |

56 |

3 |

3 |

|

250 |

588 |

922 |

1400 |

1700 |

260.8 |

299.2 |

19.0 |

|

NU 1048 M |

32148H |

240 |

360 |

56 |

3 |

3 |

|

270 |

621 |

1010 |

1200 |

1400 |

|

319.2 |

20.9 |

|

N 1052 M |

2152H |

260 |

400 |

65 |

4 |

4 |

364 |

|

644 |

998 |

1100 |

1300 |

309.2 |

|

30.8 |

|

NU 1052 M |

32152H |

260 |

400 |

65 |

4 |

4 |

|

296 |

644 |

998 |

1100 |

1300 |

|

348.4 |

31.4 |

|

NUP 1052 M |

92152H |

260 |

400 |

65 |

4 |

4 |

|

296 |

644 |

998 |

1100 |

1300 |

309.2 |

348.4 |

32.6 |

|

NU 1056 M |

32156H |

280 |

420 |

65 |

4 |

4 |

|

316 |

660 |

1060 |

980 |

1200 |

|

373.1 |

29.8 |

|

NU 1060 |

32160 |

300 |

460 |

74 |

4 |

4 |

|

340 |

990 |

1631 |

860 |

1000 |

|

407 |

45.1 |

|

NJ 1060 |

42160 |

300 |

460 |

74 |

4 |

4 |

|

340 |

990 |

1631 |

860 |

1000 |

353 |

407 |

45.1 |

|

NU 072 M |

7032172H |

360 |

540 |

57 |

5 |

5 |

|

410 |

1003 |

1749 |

700 |

900 |

|

472 |

49.0 |

|

NU 1080 |

32180 |

400 |

600 |

90 |

5 |

5 |

|

450 |

1500 |

2610 |

730 |

860 |

|

532 |

88.2 |

|

NF 212 M |

12212H |

60 |

110 |

22 |

1.5 |

1.5 |

97 |

|

72 |

80 |

5300 |

6400 |

77.3 |

92.7 |

0.950 |