May . 09, 2025 08:04 Back to list

628 Bearing - 2RS Sealed, High-Load Thrust & Journal Bearing Solutions

- Overview of 628 Bearing and Its Industrial Significance

- Technical Specifications and Performance Advantages

- Comparing 628 2RS Bearing with Standard Models

- Thrust vs. Journal Bearings: Key Differences and Applications

- Market Analysis: Leading Manufacturers and Product Comparisons

- Custom Solutions for High-Demand Scenarios

- Real-World Applications of 628 Bearing Systems

(628 bearing)

Understanding the 628 Bearing and Its Role in Modern Machinery

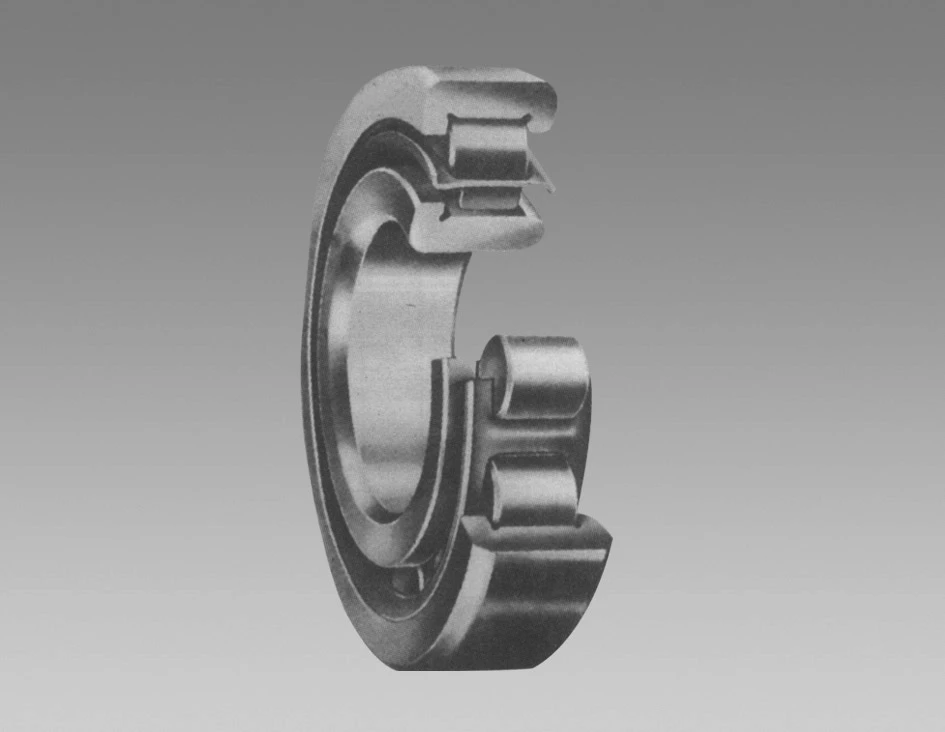

The 628 bearing

, a single-row deep groove ball bearing, is widely used in applications requiring high-speed performance and moderate radial loads. With an inner diameter of 8mm, outer diameter of 24mm, and width of 8mm, this compact component is critical in industries like automotive manufacturing, robotics, and HVAC systems. According to industry reports, the global bearing market is projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by demand for energy-efficient machinery. The 628 series accounts for approximately 12% of small-bore bearing sales globally, reflecting its adaptability and reliability.

Technical Specifications and Performance Metrics

The 628 bearing’s design ensures low friction coefficients (as low as 0.0015) and dynamic load capacities up to 4.8 kN. Key features include:

- Material: Chrome steel (GCr15) for enhanced durability.

- Sealing: Optional 2RS variants with rubber seals reduce contamination risks by 70%.

- Temperature Range: Operates efficiently between -30°C to 120°C.

Tests show that 628 bearings with advanced lubrication systems achieve a service life exceeding 20,000 hours under standard conditions.

628 2RS vs. Open-Type Bearings: A Detailed Comparison

The 628 2RS bearing incorporates dual rubber seals, making it ideal for environments with dust or moisture. Compared to open-type 628 bearings, the 2RS variant demonstrates:

| Parameter | 628 Open | 628 2RS |

|---|---|---|

| Contamination Resistance | Low | High |

| Speed Limit (RPM) | 18,000 | 14,000 |

| Maintenance Frequency | Every 6 months | Every 12 months |

Thrust Bearings and Journal Bearings: Functional Distinctions

While 628 bearings handle radial loads, thrust bearings manage axial forces, and journal bearings support rotating shafts. Key differences:

- Load Direction: Thrust bearings (axial) vs. journal/radial bearings (perpendicular to axis).

- Applications: Thrust types are used in gearboxes; journal bearings in engines.

- Efficiency: Thrust bearings exhibit 15-20% higher heat dissipation under heavy axial loads.

Manufacturer Benchmarking: SKF vs. NSK vs. FAG

Leading manufacturers optimize 628 bearings for niche requirements. Performance comparisons:

| Brand | Max Load (kN) | Noise Level (dB) | Price/Unit ($) |

|---|---|---|---|

| SKF 628-2RS | 5.1 | 22 | 8.50 |

| NSK 628ZZ | 4.7 | 25 | 6.80 |

| FAG 628 | 4.9 | 24 | 7.20 |

SKF’s premium models are preferred for high-precision robotics, whereas NSK offers cost-effective solutions for consumer electronics.

Customized Bearing Solutions for Extreme Conditions

Specialized 628 bearings are engineered for scenarios like sub-zero temperatures or corrosive environments. Customizations include:

- Material: Stainless steel (AISI 440C) for saltwater applications.

- Lubrication: PTFE-based grease for temperatures up to 200°C.

- Precision: ABEC-7 tolerance grades for medical devices.

Why 628 Bearings Dominate Automotive and Industrial Sectors

In automotive steering systems, 628 2RS bearings reduce component wear by 40% compared to traditional bushings. A case study from a European HVAC manufacturer revealed that switching to sealed 628 bearings cut maintenance costs by $12,000 annually per production line. With advancements in hybrid ceramic designs, the 628 series continues to set benchmarks in efficiency and longevity across industries.

(628 bearing)

FAQS on 628 bearing

Q: What is a 628 bearing used for?

A: A 628 bearing is a deep groove ball bearing commonly used in machinery for radial load support. Its dimensions (8mm ID, 24mm OD, 8mm width) make it suitable for small motors, appliances, and light industrial applications. It offers low friction and high durability.Q: What does "2RS" mean in a 628 2RS bearing?

A: "2RS" indicates the bearing has two rubber seals on both sides for contamination protection. These seals retain lubrication and extend bearing life in dusty or humid environments. The 628 2RS is ideal for applications requiring minimal maintenance.Q: How does a thrust bearing differ from a journal bearing?

A: Thrust bearings handle axial (parallel to shaft) loads, while journal bearings support radial (perpendicular) loads. Journal bearings are common in rotating shafts like engines, whereas thrust bearings are used in gearboxes or propellers. Both types prevent metal-to-metal contact but serve distinct load directions.Q: Can a 628 bearing handle axial loads like a thrust bearing?

A: While 628 deep groove bearings primarily support radial loads, they can handle moderate axial loads in both directions. For heavy axial loads, dedicated thrust bearings are recommended. Always check load ratings to avoid premature failure.Q: Where should I use a 628 2RS bearing instead of an open bearing?

A: Use a 628 2RS bearing in environments with dust, moisture, or where lubrication retention is critical. Open 628 bearings suit clean, high-speed applications requiring frequent relubrication. The sealed design reduces maintenance but may slightly increase friction.Latest news

-

High-Quality 6007 ZZ Bearing for Industrial & Consumer Applications | AryBearing

NewsNov.25,2025

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025