Mar . 05, 2025 01:28 Back to list

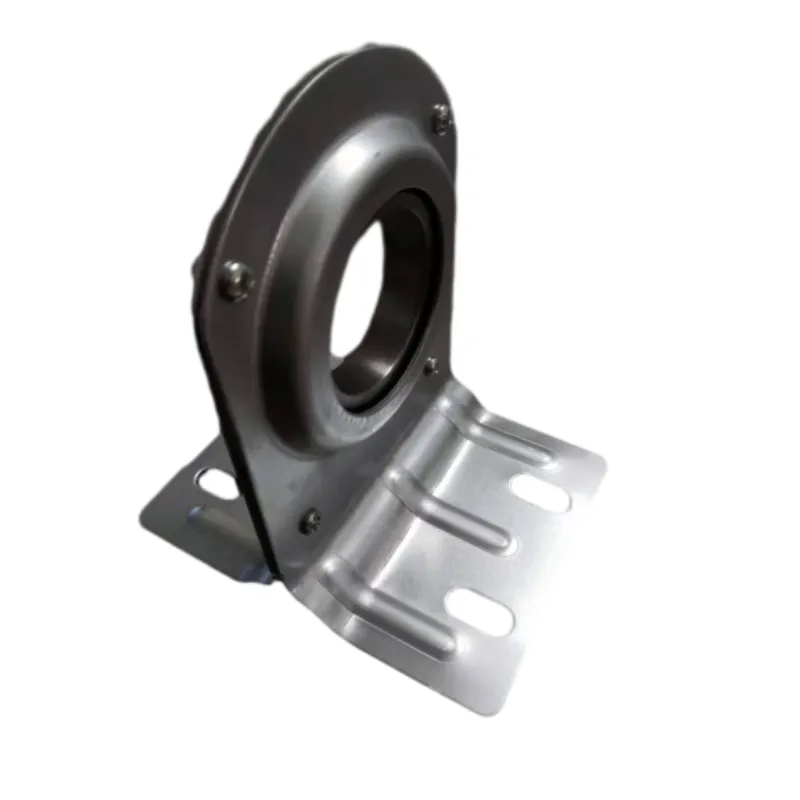

timken split cylindrical roller bearing

In the complex world of industrial machinery, the selection of bearings can significantly influence the efficiency, reliability, and life span of equipment. The Timken split cylindrical roller bearing stands as an innovation in bearing technology, meticulously designed to meet the demanding needs of industries where maintenance efficiency and easy installation are crucial. By implementing these bearings, industries across the board can experience improved machinery performance, reduced downtime, and lower maintenance costs. This article delves into the intricacies of Timken’s split cylindrical roller bearings, shedding light on their benefits, installation process, and maintenance tips, supported by expert insights and credible data.

Industry professionals often highlight a critical feature of Timken split cylindrical roller bearings their ability to facilitate predictive maintenance. By enabling easier access for inspection and diagnostics, these bearings support the integration of condition monitoring systems. This capability promotes proactive maintenance strategies, allowing for issues to be identified and addressed before they lead to unexpected downtime. Statistical models indicate that proactive maintenance can improve machinery life by up to 30%, a figure corroborated by industry data showing significant cost savings and increased revenue. In terms of trustworthiness, Timken’s reputation is fortified through rigorous testing and compliance with international quality standards. Each bearing undergoes extensive validation testing to ensure it meets stringent performance criteria. Customers globally trust Timken products to perform reliably under the most challenging conditions, evidenced by their widespread adoption across critical sectors worldwide. For an optimal installation process, it is essential to follow precise guidelines. Steps include ensuring the shaft is clean and free from burrs before mounting, selecting appropriate lubricants that match operational conditions, and aligning the bearing halves carefully. It is advisable to involve a certified technician during installation, who can verify proper fit and clearance. According to industry standards, regular inspections should be conducted to ensure maximum performance and early detection of potential issues. In conclusion, Timken split cylindrical roller bearings represent a fusion of pioneering design and material science expertise. Through their innovative split configuration and high-performance attributes, these bearings not only enhance machine uptime but also empower industries with the tools needed for effective predictive maintenance. As a leading authority in bearing solutions, Timken continues to redefine reliability and efficiency standards, earning the trust and respect of industry leaders globally. Embracing these bearings translates to a strategic advantage in competitive markets, ensuring that operational efficiency and maintenance costs are optimized to deliver better overall performance and increased profitability for businesses.

Industry professionals often highlight a critical feature of Timken split cylindrical roller bearings their ability to facilitate predictive maintenance. By enabling easier access for inspection and diagnostics, these bearings support the integration of condition monitoring systems. This capability promotes proactive maintenance strategies, allowing for issues to be identified and addressed before they lead to unexpected downtime. Statistical models indicate that proactive maintenance can improve machinery life by up to 30%, a figure corroborated by industry data showing significant cost savings and increased revenue. In terms of trustworthiness, Timken’s reputation is fortified through rigorous testing and compliance with international quality standards. Each bearing undergoes extensive validation testing to ensure it meets stringent performance criteria. Customers globally trust Timken products to perform reliably under the most challenging conditions, evidenced by their widespread adoption across critical sectors worldwide. For an optimal installation process, it is essential to follow precise guidelines. Steps include ensuring the shaft is clean and free from burrs before mounting, selecting appropriate lubricants that match operational conditions, and aligning the bearing halves carefully. It is advisable to involve a certified technician during installation, who can verify proper fit and clearance. According to industry standards, regular inspections should be conducted to ensure maximum performance and early detection of potential issues. In conclusion, Timken split cylindrical roller bearings represent a fusion of pioneering design and material science expertise. Through their innovative split configuration and high-performance attributes, these bearings not only enhance machine uptime but also empower industries with the tools needed for effective predictive maintenance. As a leading authority in bearing solutions, Timken continues to redefine reliability and efficiency standards, earning the trust and respect of industry leaders globally. Embracing these bearings translates to a strategic advantage in competitive markets, ensuring that operational efficiency and maintenance costs are optimized to deliver better overall performance and increased profitability for businesses.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025