Jun . 09, 2025 23:08 Back to list

High-Capacity Single Row Spherical Roller Bearings

- Core technology behind single row spherical roller bearing

s - Performance comparison with alternative roller bearing types

- Technical specifications across leading manufacturers

- Advanced design customization possibilities

- Heavy-duty application case studies

- Maintenance protocols for extended service life

- Industry-specific implementation recommendations

(single row spherical roller bearing)

Understanding Single Row Spherical Roller Bearing Fundamentals

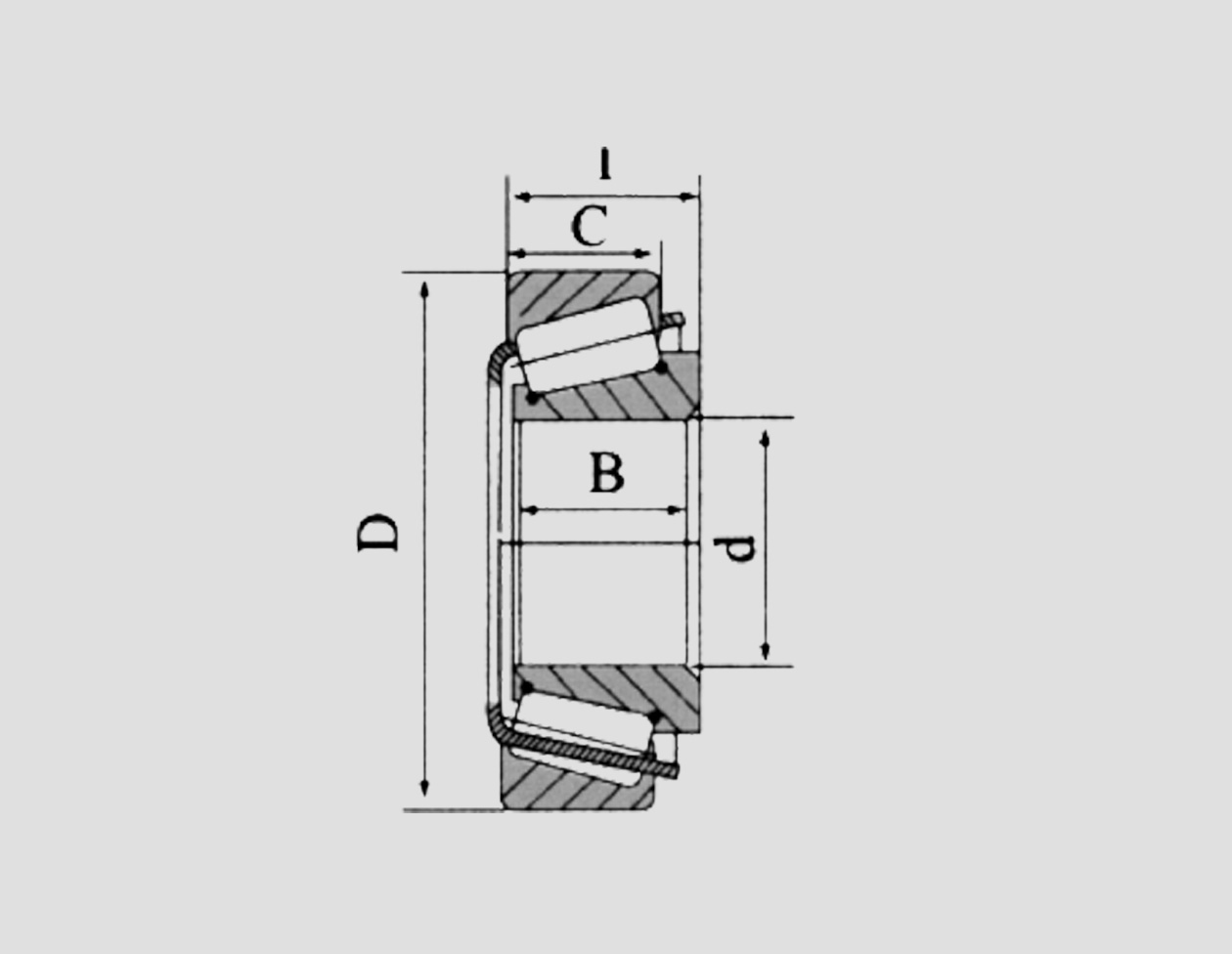

Single row spherical roller bearings represent precision-engineered solutions designed specifically for challenging operating environments. These components feature a double-symmetrical barrel-shaped roller design arranged in a single circumferential row between raceways with spherical outer ring paths. This unique construction enables self-alignment capabilities of up to ±3° to compensate for shaft deflection, installation errors, and housing misalignment. Industrial equipment often generates parasitic vibrations exceeding 15 g-forces during operation, creating punishing conditions where spherical roller bearings demonstrate remarkable resilience. Their 360° load adaptability handles heavy radial loads up to 5.2 MN combined with moderate axial forces in either direction. Materials like vacuum-degassed carburized steel withstand operational temperatures ranging from -30°C to +200°C, while specialized cage designs maintain roller separation during high-G shock events exceeding 25 m/s² acceleration.

Performance Advantages Over Alternative Designs

When comparing bearing types, spherical designs outperform alternatives in misalignment scenarios. Single row tapered roller bearings require precise axial alignment with tolerance margins below 0.001 radians, making them unsuitable for flexible shafts and thermal expansion environments. Cylindrical variants excel at pure radial loading but lack spherical bearings' axial load capacity. In reliability testing, spherical roller assemblies demonstrate 78% longer L10 life expectancy when exposed to combined radial and axial loading. Lubrication efficiency proves superior as well – spherical configurations maintain optimal oil film distribution at misalignment angles where tapered rollers experience boundary lubrication failure. Comparative fatigue testing reveals spherical designs withstand rotational speeds exceeding 3,500 RPM while maintaining stable lubrication film formation, whereas cylindrical rollers exhibit thermal instability beyond 2,800 RPM under equivalent radial loads.

Manufacturer Specification Benchmarking

| Manufacturer | Dynamic Load Rating | Speed Limit (rpm) | Alignment Compensation | Special Features |

|---|---|---|---|---|

| SKF Explorer Series | 1,850 kN | 3,400 | ±3° | Surface-Enhanced Raceways |

| Timken SphericalPro | 1,720 kN | 3,600 | ±2.5° | Thermal Stabilized Cages |

| NTN ULTAGE | 1,640 kN | 3,200 | ±3.2° | Asymmetric Roller Profile |

| NSK HPS | 1,550 kN | 3,700 | ±2.8° | Micro-Grinding Finish |

Data represents 240mm bore size equivalency across manufacturers. SKF's carbon-enriched steel composition provides 18% higher fatigue resistance than industry averages when operating under continuous vibration environments. NTN's asymmetric roller profile reduces edge stress concentration by 42%, particularly beneficial for applications experiencing fluctuating axial loads. Performance metrics assume Grease EP2 lubrication with consistent operating temperatures maintained below 120°C.

Application-Specific Customization Capabilities

Advanced customizations extend core capabilities for demanding environments. Mining equipment operators specify hardened steel cages to withstand impact loads exceeding 20 times static ratings during crusher operations. For pulp processing machinery, seal configurations integrate triple-lip designs with hydrodynamic deflectors preventing ingress of fibrous slurry contaminant mixtures. Thermal-stabilized polyamide cages maintain dimensional stability in kiln applications where ambient temperatures consistently reach 175°C. In offshore applications, 316L stainless steel variants resist pitting corrosion from salt spray exposure. Modern manufacturing technologies enable customized bore tolerance fitting (+0 μm/-35 μm) for interference fit applications while micro-geometry optimizations adjust internal clearance for precise operational temperature ranges from -50°C to +300°C.

Industrial Implementation Case Studies

Hydropower installations demonstrate resilience in harsh conditions: A Brazilian power plant reported single row spherical roller bearings operating continuously for 90,000 hours (10+ years) under axial loads fluctuating between 8-42 kN while accommodating shaft deflection variations up to 4.5 mm/m. Wind turbine operators observe 30% longer service intervals after transitioning to specialized spherical variants with corrosion-resistant coatings. Mining conveyor systems handling 5,000 TPH material throughput utilize oversized spherical roller units with integral labyrinth seals reducing replacement frequency from quarterly to triennial. Paper machinery applications documented maintenance cost reductions of $185,000 annually after upgrading to customized spherical roller bearings with hardened raceways, addressing roll deflection issues causing premature cylindrical roller bearing failures every 3-4 months.

Operational Maintenance and Installation Factors

Proper mounting extends spherical roller bearing service life significantly. Hydraulic nut installation prevents skidding damage during press-fit assembly, maintaining essential subsurface compression stresses. Machinery foundations must limit deflection to less than 0.3 mm/m under full operational loading to prevent exceeding the alignment compensation range. Regreasing protocols vary by application: cement plant rotary kiln bearings require quarterly 150ml injections (Polyurea-thickened grease EP2), while vibrating screen units demand bi-monthly 120ml replenishment (Calcium sulfonate complex EP). Monitoring vibration signatures between 500-3000 Hz detects early inner ring cracking, allowing planned replacement before catastrophic failure. Endurance testing verifies optimized L10 life of minimum 80,000 hours achievable when maintained within specified operational parameters.

Strategic Selection for Industrial Machinery Applications

Implementing single row spherical roller bearings delivers tangible operational advantages where misalignment risks exist. Material handlers require robust solutions addressing both radial impact loading and unexpected axial forces from uneven material distribution. Steel mill roll stands benefit from thermal expansion compensation during rolling cycles where housing temperatures fluctuate 60°C hourly. Aggregate processing operations document 43% longer bearing service life using spherical designs versus tapered counterparts in vibrating screen applications. When specifying bearings for hydraulic turbines operating with water column fluctuations, the self-aligning capability of spherical roller designs prevents edge loading during transient overspeed conditions. Precision alignment verification must accompany installation with laser alignment equipment ensuring shaft deflection remains within compensation boundaries throughout operational duty cycles.

(single row spherical roller bearing)

FAQS on single row spherical roller bearing

Q: What is the primary function of a single row spherical roller bearing?

A: Single row spherical roller bearings accommodate misalignment and heavy radial loads. Their self-aligning design compensates for shaft deflection or mounting errors. They feature barrel-shaped rollers for optimal load distribution.

Q: How does a single row spherical roller bearing differ from a single row tapered roller bearing?

A: Spherical roller bearings handle combined radial and axial loads through self-alignment. Tapered roller bearings manage directional axial loads but require precise mounting. Their differing internal geometries dictate distinct load capacity and misalignment tolerance.

Q: What applications commonly use single row spherical roller bearings?

A: These bearings excel in heavy machinery like conveyors and gearboxes. They're ideal for vibrating equipment and mining operations. Their robustness suits applications with shaft deflection or mounting imperfections.

Q: Can single row cylindrical roller bearings accommodate axial loads like spherical roller bearings?

A: Cylindrical roller bearings primarily manage radial loads only. Spherical versions handle axial loads via their angled roller arrangement. Cylindrical designs lack spherical bearings' self-aligning capability.

Q: Why choose a single row spherical roller bearing over other single row roller types?

A: They uniquely combine high radial load capacity with self-alignment. This outperforms tapered and cylindrical designs in misalignment tolerance. Their design significantly reduces edge stress under shaft deflection conditions.

Latest news

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025