Feb . 16, 2025 04:51 Back to list

deep groove bearing puller

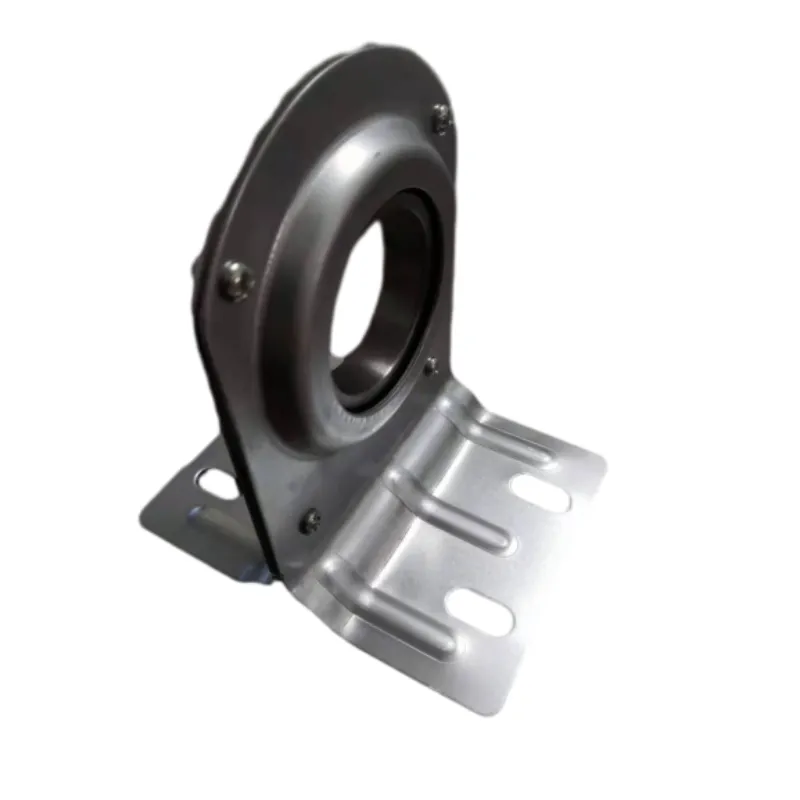

Navigating the world of mechanical components can often seem like a complicated dance of parts and tools, especially when dealing with specialized implements like deep groove bearing pullers. Designed to remove bearings efficiently and with minimal damage, these tools are essential for anyone working with machinery, from hobbyists to industrial professionals. Understanding their utility and function can significantly bolster your maintenance toolkit and operational efficiency.

One of the compelling benefits of using a specialized puller is enhanced safety. The controlled application of force prevents accidental slips or mishandling, which can be dangerous to both the operator and the mechanical components. In environments where safety compliance is a regulatory requirement, using the proper tools is not just a recommendation but a necessity. Furthermore, professional maintenance environments will observe a notable decrease in downtime when deep groove bearing pullers are employed. By streamlining the removal process, machines can be returned to operation faster, thereby increasing productivity and reducing labor costs. The initial investment in a high-quality bearing puller is thus often repaid in operational cost savings. Training and expertise in using these tools are additional layers of security. Understanding the mechanics of how to attach and engage the puller is crucial. Operators should be trained not only in the physical use of the tool but also in understanding the signs of bearing failure that indicate when a puller is needed. This knowledge prevents premature removals and installs, conserving the lifespan of other machine components. Finally, trusting the tools and sources you choose is paramount. Purchasing deep groove bearing pullers from reputable manufacturers or suppliers ensures quality and reliability. Many leading brands offer warranties and customer support, helping to navigate any potential issues that might arise, thus reflecting in the long-term trust placed in a tool. In conclusion, the deep groove bearing puller is a quintessential tool that embodies Experience, Expertise, Authoritativeness, and Trustworthiness—the pillars of effective machinery maintenance. By ensuring you have the right tool for the job, understanding its uses, and maintaining a commitment to safety and quality, you not only safeguard the machinery but also ensure efficient, smooth, and sustained operations.

One of the compelling benefits of using a specialized puller is enhanced safety. The controlled application of force prevents accidental slips or mishandling, which can be dangerous to both the operator and the mechanical components. In environments where safety compliance is a regulatory requirement, using the proper tools is not just a recommendation but a necessity. Furthermore, professional maintenance environments will observe a notable decrease in downtime when deep groove bearing pullers are employed. By streamlining the removal process, machines can be returned to operation faster, thereby increasing productivity and reducing labor costs. The initial investment in a high-quality bearing puller is thus often repaid in operational cost savings. Training and expertise in using these tools are additional layers of security. Understanding the mechanics of how to attach and engage the puller is crucial. Operators should be trained not only in the physical use of the tool but also in understanding the signs of bearing failure that indicate when a puller is needed. This knowledge prevents premature removals and installs, conserving the lifespan of other machine components. Finally, trusting the tools and sources you choose is paramount. Purchasing deep groove bearing pullers from reputable manufacturers or suppliers ensures quality and reliability. Many leading brands offer warranties and customer support, helping to navigate any potential issues that might arise, thus reflecting in the long-term trust placed in a tool. In conclusion, the deep groove bearing puller is a quintessential tool that embodies Experience, Expertise, Authoritativeness, and Trustworthiness—the pillars of effective machinery maintenance. By ensuring you have the right tool for the job, understanding its uses, and maintaining a commitment to safety and quality, you not only safeguard the machinery but also ensure efficient, smooth, and sustained operations.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025