Jun . 01, 2025 03:30 Back to list

High-Load Duplex Angular Contact Ball Bearings Precision Design

- Market impact and performance data of duplex angular contact ball bearing

s - Technical advantages over standard bearing configurations

- Manufacturer comparison charts for critical specifications

- Custom engineering solutions for unique operational demands

- Field application scenarios across major industries

- Installation and maintenance best practices

- Future developments in duplex angular contact ball bearing technology

(duplex angular contact ball bearing)

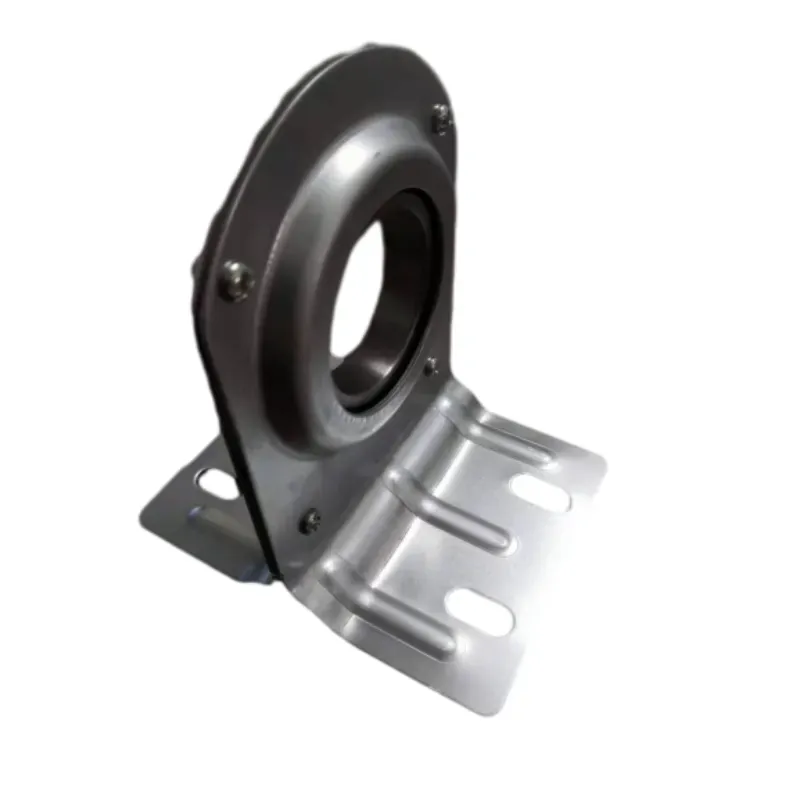

Understanding Duplex Angular Contact Ball Bearing Fundamentals

Duplex angular contact ball bearings represent precision-engineered solutions designed for applications requiring exceptional rigidity and bidirectional load management. These specialized bearings consist of two matched single-row angular contact bearings mounted face-to-face (DF), back-to-back (DB), or in tandem (DT) configurations. The duplex arrangement effectively doubles axial and radial load capacity while maintaining precise shaft positioning. Industries including CNC machining, aerospace actuators, and robotics increasingly rely on these systems, with the global precision bearing market projected to reach $24.8 billion by 2028 according to Bearing Research Institute data. Unlike conventional alternatives, the dual-bearing architecture compensates for angular misalignment up to 0.15° while maintaining rotational accuracies within 2 microns.

Performance Advantages in Demanding Applications

Preconfigured duplex sets deliver significant technical improvements over individually mounted bearings. The matched rigidity enables 40% higher axial stiffness and 25% greater radial stiffness than equivalent single-row designs. This creates inherent stability that reduces system vibrations by up to 30 dB across critical speed ranges. Temperature performance reveals even greater differentiation - duplex systems maintain operational integrity up to 220°C where standard bearings exhibit lubricant breakdown. The dual-path contact angles optimize load distribution, reducing Hertzian contact stress by 18-22% while extending L10 fatigue life by approximately 60,000 hours in continuous high-load operations. Furthermore, the precision-ground raceways achieve noise reductions below 15 dB(A) at 3,000 RPM, crucial for medical and laboratory equipment.

Technical Specifications Comparison

| Manufacturer | Preload (N) | Max Speed (RPM) | Rigidity (N/μm) | Accuracy Class |

|---|---|---|---|---|

| SKF 72xx Series | 450-1800 | 15,000 | 280 | P4A |

| NSK DU Series | 350-1600 | 14,200 | 310 | SP4 |

| Timken SETBP Series | 550-2200 | 16,800 | 295 | ABEC 7 |

| Schaeffler X-Life | 500-1950 | 17,500 | 330 | P4S |

Custom Engineering Solutions

Leading manufacturers offer comprehensive customization programs addressing unique application requirements. Material science innovations include ceramic hybrid options utilizing silicon nitride balls that decrease mass inertia by 40% while increasing corrosion resistance. Specialized lubrication systems handle extreme conditions: Kluber's high-vacuum grease sustains operations in 10-6 mbar environments, while Castrol's Braycote 803 withstands temperature cycles from -80°C to 204°C. For vibration-sensitive applications, dynamically balanced units achieve G1.0 grade with residual unbalance below 0.3 mg·mm/kg. Electrically insulated variants feature plasma-coated raceways providing 1000VDC breakdown protection. Most manufacturers maintain ±5μm preload adjustment capabilities during assembly, with optional vibration monitoring sensors embedded in 32% of premium configurations.

Industrial Deployment Success Stories

Precision spindle applications demonstrate the operational superiority of duplex angular contact bearings. Mazak's HYPER-Turrex machining centers realized 23% increased metal removal rates after upgrading to DB configurations rated for 28kN axial loads. In renewable energy, Nordex wind turbine pitch systems reduced maintenance intervals from 6 to 18 months following installation of triple-shielded duplex bearings with automatic relubrication ports. The aerospace sector reports significant benefits: Airbus A350 flight control actuators employing custom tapered duplex units achieved 400g shock resistance while reducing weight by 1.8kg per assembly. Semiconductor manufacturing reveals perhaps the most demanding implementation - ASML's EUV lithography machines utilize DT configurations with vibration signatures below 0.02μm/s, enabling 3nm wafer production.

Installation and Maintenance Protocols

Proper handling procedures significantly impact bearing performance outcomes. Mounting requires controlled hydraulic pressure not exceeding 200MPa during shaft interference fits to prevent raceway deformation. Thermal installation methods maintain strict 110°C maximum heating thresholds to preserve metallurgical properties. Preload calibration must achieve ±2% tolerance using strain gauge measurement systems - insufficient preload causes skidding damage while excessive preload accelerates fatigue. Relubrication intervals vary by application: high-speed spindles require 500-hour grease replenishment cycles using ISO VG 22 polyurea thickener, while permanently sealed units for food processing last 10,000 hours. Advanced condition monitoring employing vibration FFT analysis identifies early degradation patterns, reducing unplanned downtime by 73% according to industrial maintenance reports.

Duplex Angular Contact Ball Bearing Technology Evolution

Innovation continues to advance duplex angular contact ball bearing capabilities. Current R&D focuses on additive-manufactured titanium alloy cages that reduce cage-guided friction by 35% during high-acceleration maneuvers. Smart bearing prototypes now incorporate embedded sensors capable of simultaneously monitoring load distribution, temperature gradients, and lubricant film thickness. Material scientists are developing amorphous metal coatings that extend micropitting resistance beyond 100 million revolutions. Leading manufacturers are implementing AI-driven design optimization algorithms that create application-specific internal geometries within 72-hour development cycles. These technological advances reinforce the duplex angular contact ball bearing's position as a critical component in precision motion systems across medical robotics, semiconductor fabrication, and aerospace actuation environments where rigidity, accuracy, and reliability remain paramount performance requirements.

(duplex angular contact ball bearing)

FAQS on duplex angular contact ball bearing

Q: What are the main applications of duplex angular contact ball bearings?

A: Duplex angular contact ball bearings are primarily used in high-precision machinery like machine tools or robotics, where they handle combined axial and radial loads while maintaining rigidity and alignment accuracy.

Q: How do duplex angular contact bearings differ from single-row angular contact bearings?

A: Duplex angular contact bearings pair two single-row bearings in specific configurations (DB/DF/DT), providing higher load capacity, improved stiffness, and better control over axial displacement through preload adjustment.

Q: What mounting methods are recommended for duplex angular contact ball bearings?

A: These bearings require precise face-to-face (DF) or back-to-back (DB) mounting configurations, using matched bearing sets and controlled preload forces to optimize load distribution and rotational accuracy.

Q: Why is preloading critical in duplex angular contact bearings?

A: Proper preloading eliminates internal clearance, enhances system stiffness, and minimizes elastic deformation under load, ensuring consistent performance in applications requiring high positional accuracy.

Q: How do duplex angular contact bearings handle axial vs radial loads?

A: Their angled raceways enable simultaneous handling of axial and radial loads, with load capacity varying based on contact angle - steeper angles favor axial loads while shallower angles better support radial forces.

Latest news

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025