Jan . 10, 2025 08:43 Back to list

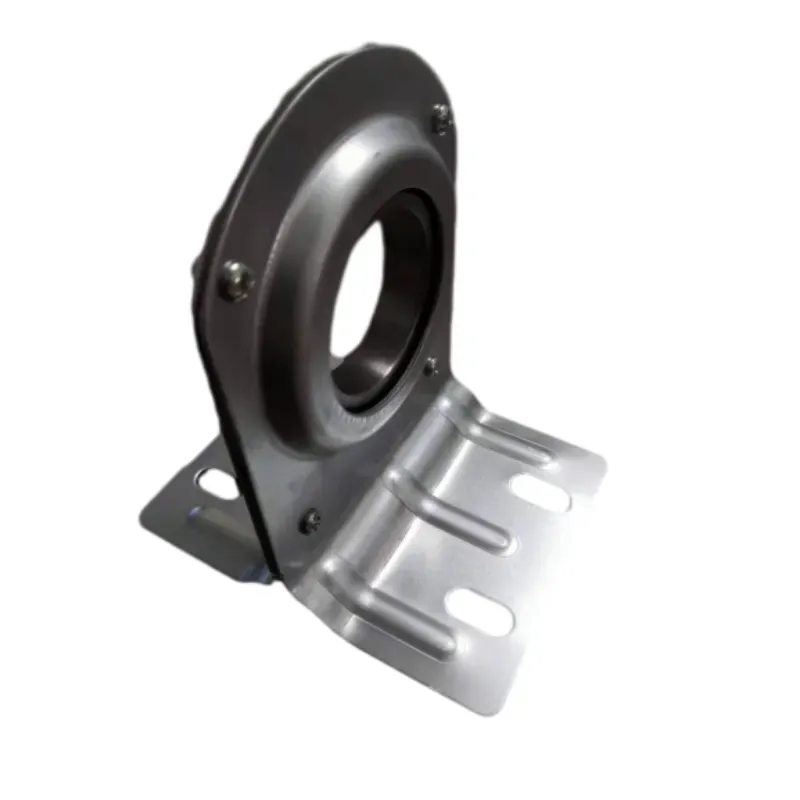

bearing testing machine

Bearing testing machines are crucial instruments in various industries that rely on the precision and durability of their components. These machines ensure bearings meet stringent quality standards and perform optimally under different operational conditions. A deeper understanding of their use and benefits reveals their significance in engineering, manufacturing, and production.

Experience plays a critical role in the development and use of bearing testing machines. Laboratories and R&D facilities employing these machines gain extensive experience through continuous use, allowing them to refine test processes and innovate new testing methodologies. Experienced technicians are instrumental in interpreting complex data, translating results into actionable improvements in bearing design or production processes. This cumulative knowledge enhances their value proposition, offering clients deeply insightful consultations based on empirical data. Trustworthiness is paramount when it comes to the application of bearing testing machines, as the stakes are often high. Industries depend on the results these machines provide to ensure the reliability and safety of their products. Manufacturers of testing machines build trust through extensive warranties, responsive customer service, and rigorous testing of their own equipment in various scenarios. This approach ensures that potential customers can rely on the integrity of the testing results provided by these machines. Therefore, when considering the acquisition of a bearing testing machine, it is vital to assess the manufacturer's track record in expertise, authoritative adherence to industry standards, and the overall trustworthiness of their offerings. Additionally, tapping into the experiences of other industry players who have successfully utilized these machines can provide valuable insights and mitigate risks. As industries continue to demand higher levels of efficiency and reliability from their components, the role of bearing testing machines will only grow in prominence. Whether for quality control, R&D, or failure analysis, these machines provide indispensable data that drives innovation and enhances product performance. Choosing the right machine with the backing of a reputable manufacturer can be a defining factor in maintaining competitiveness in an increasingly demanding market.

Experience plays a critical role in the development and use of bearing testing machines. Laboratories and R&D facilities employing these machines gain extensive experience through continuous use, allowing them to refine test processes and innovate new testing methodologies. Experienced technicians are instrumental in interpreting complex data, translating results into actionable improvements in bearing design or production processes. This cumulative knowledge enhances their value proposition, offering clients deeply insightful consultations based on empirical data. Trustworthiness is paramount when it comes to the application of bearing testing machines, as the stakes are often high. Industries depend on the results these machines provide to ensure the reliability and safety of their products. Manufacturers of testing machines build trust through extensive warranties, responsive customer service, and rigorous testing of their own equipment in various scenarios. This approach ensures that potential customers can rely on the integrity of the testing results provided by these machines. Therefore, when considering the acquisition of a bearing testing machine, it is vital to assess the manufacturer's track record in expertise, authoritative adherence to industry standards, and the overall trustworthiness of their offerings. Additionally, tapping into the experiences of other industry players who have successfully utilized these machines can provide valuable insights and mitigate risks. As industries continue to demand higher levels of efficiency and reliability from their components, the role of bearing testing machines will only grow in prominence. Whether for quality control, R&D, or failure analysis, these machines provide indispensable data that drives innovation and enhances product performance. Choosing the right machine with the backing of a reputable manufacturer can be a defining factor in maintaining competitiveness in an increasingly demanding market.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025