Jan . 10, 2025 08:53 Back to list

combine harvester bearings

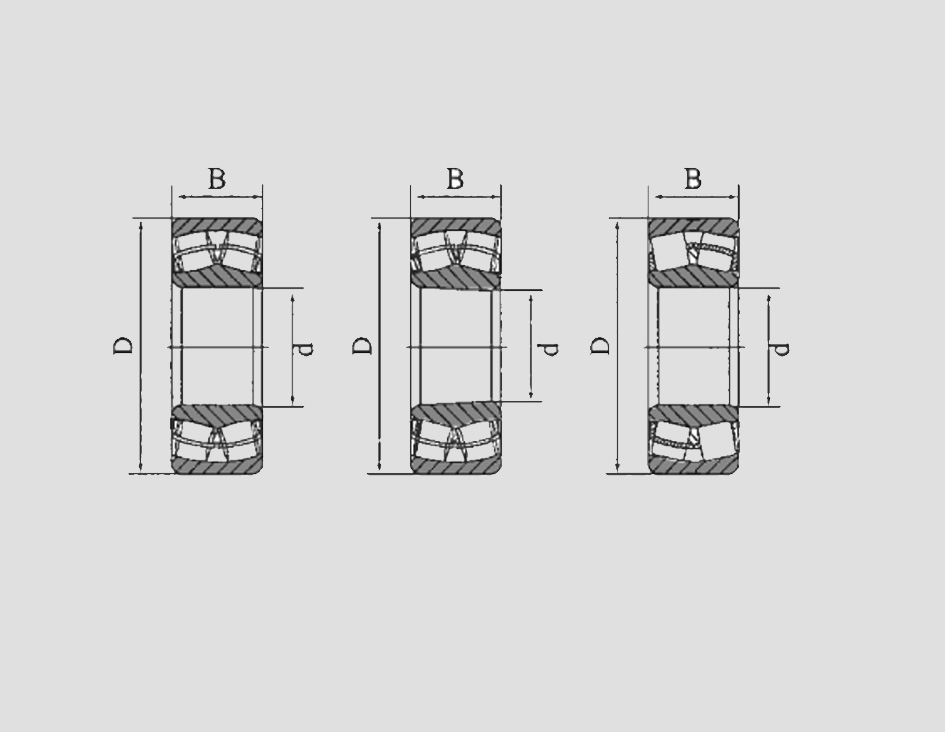

In the world of modern agriculture, few pieces of machinery are as crucial as the combine harvester. Integral to its functionality are the combine harvester bearings — components that ensure the smooth operation of this agricultural powerhouse. For those in the agricultural industry, understanding the significance of these bearings, their selection, and maintenance becomes pivotal to maximizing efficiency and productivity.

In recent years, innovations in combine harvester bearings have introduced advanced materials and designs that offer greater resistance to wear and tear. For instance, some manufacturers have developed bearings that self-lubricate, significantly reducing maintenance demands. Farmers and agricultural technicians staying current with these advancements can dramatically improve their operational efficiencies. From an authoritative perspective, using OEM (Original Equipment Manufacturer) parts is often advocated. These components are specifically designed for compatibility with particular combine harvester models, ensuring optimal performance. While aftermarket options might present immediate cost savings, they could compromise long-term reliability and machine efficiency, sometimes leading to greater expenses due to unexpected failures. For agricultural operations relying on the seamless function of their machines, establishing a preventative maintenance regime is invaluable. This includes not just routine checks, but also storing spare bearings and other critical components to minimize downtime during the harvest rush. Collaborating with specialists who have authoritative knowledge in machinery parts can transform how efficiently your combine harvester operates. In conclusion, the role of combine harvester bearings cannot be overstated. These components are fundamental to the machine's performance, and their selection, maintenance, and replacement involve sophisticated knowledge and expertise. By investing in quality bearings and adhering to rigorous upkeep practices, agricultural operations can trust in the reliability of their machinery. As agriculture continues to advance technologically, so too should the strategies employed to maintain crucial machinery parts.

In recent years, innovations in combine harvester bearings have introduced advanced materials and designs that offer greater resistance to wear and tear. For instance, some manufacturers have developed bearings that self-lubricate, significantly reducing maintenance demands. Farmers and agricultural technicians staying current with these advancements can dramatically improve their operational efficiencies. From an authoritative perspective, using OEM (Original Equipment Manufacturer) parts is often advocated. These components are specifically designed for compatibility with particular combine harvester models, ensuring optimal performance. While aftermarket options might present immediate cost savings, they could compromise long-term reliability and machine efficiency, sometimes leading to greater expenses due to unexpected failures. For agricultural operations relying on the seamless function of their machines, establishing a preventative maintenance regime is invaluable. This includes not just routine checks, but also storing spare bearings and other critical components to minimize downtime during the harvest rush. Collaborating with specialists who have authoritative knowledge in machinery parts can transform how efficiently your combine harvester operates. In conclusion, the role of combine harvester bearings cannot be overstated. These components are fundamental to the machine's performance, and their selection, maintenance, and replacement involve sophisticated knowledge and expertise. By investing in quality bearings and adhering to rigorous upkeep practices, agricultural operations can trust in the reliability of their machinery. As agriculture continues to advance technologically, so too should the strategies employed to maintain crucial machinery parts.

Next:

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025