កុម្ភៈ . 16, 2025 07:46 Back to list

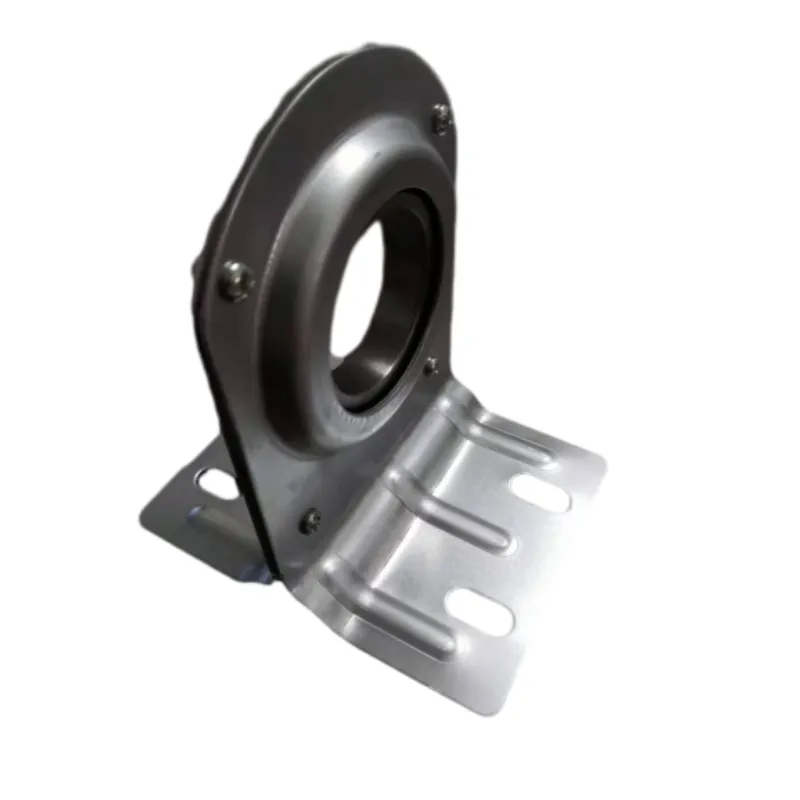

deep groove ball bearing

When considering the importance of component selection for mechanical systems, the diameter of a bearing like the 6005 model holds critical significance. Components such as bearings are fundamental to ensuring the efficiency and longevity of machinery. The 6005 bearing, with a specific focus on its diameter, serves as a quintessential example of how precise specifications in component design can lead to a marked improvement in mechanical performance.

Furthermore, the authority in the production of 6005 bearings is evident through adherence to quality control processes. Reputable manufacturers maintain rigorous testing environments to ensure each bearing meets precise specifications. This is especially true for the diameter, which if even slightly off, can lead to exponential system inefficiencies. Such manufacturers often provide extensive documentation and certification regarding the bearing's specifications, testifying to their commitment to high-quality production standards. In terms of trustworthiness, consumer confidence in the 6005 bearing derives from both historical performance data and ongoing field studies. These bearings have been vetted time and again in various high-demand applications, demonstrating their capability to function reliably over extended periods. When sourced from reputable providers, the 6005 bearing’s diameter is precisely calibrated to fit seamlessly into diverse applications, minimizing downtime and maximizing productivity. Moreover, the choice of bearing diameter also impacts energy efficiency. A properly sized bearing reduces unnecessary friction, thus conserving energy and enhancing the system's overall efficiency. This is particularly relevant in industries that operate continuously and cannot afford any loss of efficiency. The 6005 bearing's optimal performance thus contributes significantly to sustainable industrial practices by reducing operational energy consumption. In conclusion, the 6005 bearing's diameter is more than just a measurement; it embodies the intersection of precise engineering, material science, and manufacturing excellence. Its critical role in various applications underscores the importance of precision and reliability in industrial components. For businesses looking to optimize their mechanical systems, understanding the significance of bearing diameter, especially for standard models like the 6005, is imperative. By ensuring that these components perform to the highest standards, companies can achieve greater efficiency, reduced operational costs, and an extended lifespan for their machinery.

Furthermore, the authority in the production of 6005 bearings is evident through adherence to quality control processes. Reputable manufacturers maintain rigorous testing environments to ensure each bearing meets precise specifications. This is especially true for the diameter, which if even slightly off, can lead to exponential system inefficiencies. Such manufacturers often provide extensive documentation and certification regarding the bearing's specifications, testifying to their commitment to high-quality production standards. In terms of trustworthiness, consumer confidence in the 6005 bearing derives from both historical performance data and ongoing field studies. These bearings have been vetted time and again in various high-demand applications, demonstrating their capability to function reliably over extended periods. When sourced from reputable providers, the 6005 bearing’s diameter is precisely calibrated to fit seamlessly into diverse applications, minimizing downtime and maximizing productivity. Moreover, the choice of bearing diameter also impacts energy efficiency. A properly sized bearing reduces unnecessary friction, thus conserving energy and enhancing the system's overall efficiency. This is particularly relevant in industries that operate continuously and cannot afford any loss of efficiency. The 6005 bearing's optimal performance thus contributes significantly to sustainable industrial practices by reducing operational energy consumption. In conclusion, the 6005 bearing's diameter is more than just a measurement; it embodies the intersection of precise engineering, material science, and manufacturing excellence. Its critical role in various applications underscores the importance of precision and reliability in industrial components. For businesses looking to optimize their mechanical systems, understanding the significance of bearing diameter, especially for standard models like the 6005, is imperative. By ensuring that these components perform to the highest standards, companies can achieve greater efficiency, reduced operational costs, and an extended lifespan for their machinery.

Next:

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025