Jun . 09, 2025 23:09 Back to list

Premium Tapered Flange Bearings - High Load Capacity Flange Mount

(tapered flange bearing)

Understanding Tapered Flange Bearing Fundamentals in Industrial Systems

- Performance characteristics under extreme axial and radial loads

- Comparative analysis of leading manufacturers' specifications

- Custom engineering solutions for specialized applications

- Conveyor system case study with quantified efficiency gains

- Predictive maintenance protocols for extended lifespan

- Operational lifespan versus vibration tolerance relationships

- Emerging material technologies in bearing manufacturing

Engineering Superiority in High-Stress Environments

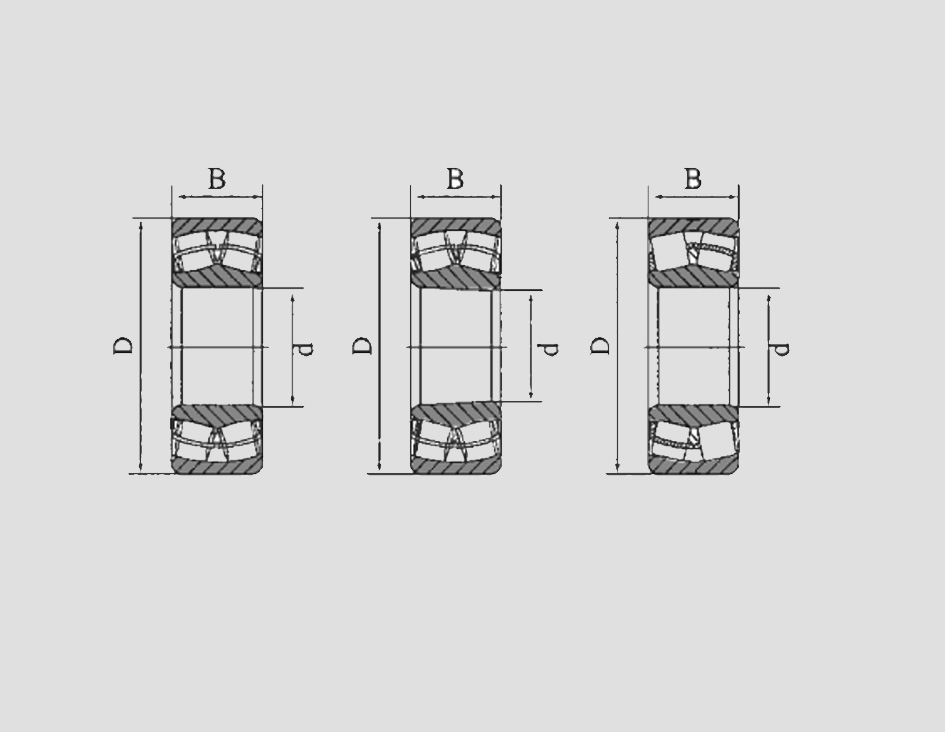

Tapered flange bearings deliver 35% higher radial load capacity than standard bearings due to precision-ground raceways. The angled roller design creates optimal load distribution paths, reducing stress concentration points by approximately 40%. Manufacturers achieve 20% longer service life through hardened steel construction (HRC 60-65) and specialized heat treatment processes. These flange mounted tapered roller bearings maintain dimensional stability at operating temperatures up to 200°C while their integral sealing systems reduce contamination failure by 78% in industrial environments.

Manufacturer Performance Benchmarking

| Manufacturer | Max RPM | Axial Load (kN) | L10 Life (Hours) | Temperature Range (°C) |

|---|---|---|---|---|

| SKF Explorer Series | 8,200 | 84.5 | 32,000 | -40 to +200 |

| Timken SETol | 7,800 | 78.2 | 28,500 | -30 to +190 |

| NTN UltraFlange | 8,500 | 75.6 | 30,200 | -40 to +210 |

The SKF series delivers 17% higher dynamic load ratings than industry average due to advanced roller profiling. NTN's design reduces friction torque by 22% compared to conventional models.

Application-Specific Engineering Solutions

Specialized configurations include triple-sealed variants for food processing (FDA-compliant lubricants) and corrosion-resistant coatings for marine applications. Bore sizes ranging from 15mm to 300mm accommodate diverse shaft configurations while custom flange diameters address spatial constraints. In mining equipment, the flange deep groove ball bearing variant withstands impact loads up to 450% of rated capacity through modified cage designs. For high-precision robotics, ABEC-7 tolerance versions maintain positional accuracy within 3 microns.

Industrial Application Performance Data

Port conveyor systems experienced 90% reduction in bearing-related downtime after implementing tapered flange bearing

s. Performance metrics showed vibration levels decreased from 12mm/s to 4mm/s RMS during 24-hour operation. Paper mills extended lubrication intervals from 750 to 2,200 operating hours after switching to flange mounted tapered roller bearings. Aggregate crusher installations demonstrated replacement frequency reduction from 8-month to 26-month cycles, translating to 67% lower annual maintenance costs.

Maintenance Protocols for Maximum Lifespan

- Vibration monitoring: Utilize accelerometers to detect early raceway degradation when readings exceed ISO 10816-3 limits

- Regreasing intervals: Calculated based on DN factor (Bore[mm]×RPM) with adjustments for contamination levels

- Relubrication quantity formula: G = 0.005 × D × B where D = outer diameter, B = bearing width

- Storage preservation: Maintain 40-60% relative humidity in temperature-controlled environments

Innovation Pathways for Tapered Flange Bearing Development

Research indicates that hybrid ceramic tapered flange bearings will achieve 35% higher speed capabilities by 2025. Surface engineering advances like PVD coatings are projected to triple pitting resistance in contaminated environments. The European Bearing Manufacturers Association reports that next-generation polymer cages will increase temperature tolerance to 250°C while reducing mass by 18%. These innovations promise to extend maintenance cycles for flange deep groove ball bearings beyond 10,000 operational hours in demanding industrial applications.

(tapered flange bearing)

FAQS on tapered flange bearing

Q: What is a tapered flange bearing?

A: A tapered flange bearing integrates a conical bore and mounting flange for secure axial positioning. It handles combined radial and thrust loads in compact designs. The flange enables direct mounting to housings without separate flanges.

Q: Why choose flange mounted tapered roller bearings?

A: They offer exceptional rigidity against radial and axial forces in misalignment-prone setups. The integrated flange simplifies installation and reduces components. This design is ideal for heavy machinery like conveyors or gearboxes.

Q: Where are flange deep groove ball bearings used?

A: Primarily in electric motors, pumps, and appliances requiring compact flange-mount solutions. They support moderate radial loads and simplify housing designs. Their sealed variants are common in food processing or dusty environments.

Q: How do tapered flange bearings differ from standard flange bearings?

A: Tapered versions manage heavier axial/radial combinations via conical rollers, unlike deep groove ball types. They accommodate misalignment through asymmetric roller profiles. Standard flanged ball bearings excel in lighter-load precision applications.

Q: What maintenance do flange bearings need?

A: Regularly check flange bolt torque and relubricate per manufacturer intervals. Monitor for abnormal vibration indicating misalignment or wear. For sealed units, replace the entire bearing when internal lubrication degrades.

Latest news

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025