febr . 20, 2025 13:49 Back to list

Cylindrical Roller Bearings

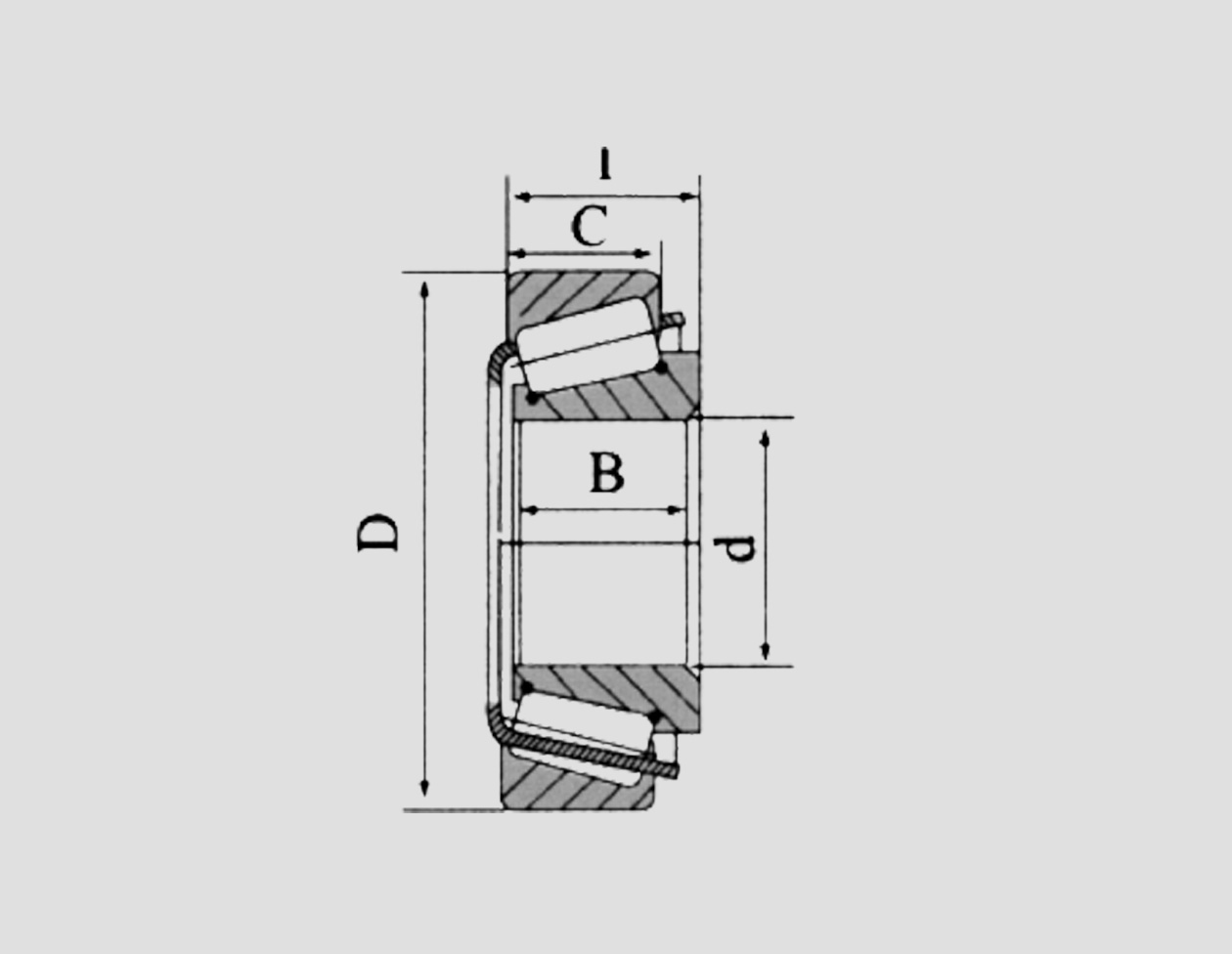

The world of industrial machinery relies heavily on the integrity and reliability of its components, among which double cylindrical roller bearings play a pivotal role. As an instrumental part in various applications, these bearings offer the kind of performance and durability that's essential in demanding environments. Understanding their structure, advantages, and usage can provide insights into why they are the preferred choice for high-stress applications worldwide.

When it comes to authority in the bearing sector, numerous OEMs and aftermarket suppliers have established reputations based on expertise with these components. Companies with decades of experience have documented success stories where the deployment of double cylindrical roller bearings has significantly improved operational throughput and machinery reliability. This credence from established industry leaders adds a layer of trustworthiness, as these components are critical in the seamless operation of complex machinery. Real-world applications of double cylindrical roller bearings often showcase their effectiveness in settings that demand robust and reliable operation. In wind turbines, for instance, these bearings support the main rotor shaft, requiring both strength and precision due to the varying loads induced by wind conditions. Similarly, in the steel manufacturing sector, they accommodate the heavy rolling loads found in steel mills, ensuring operational integrity during intense production cycles. Furthermore, advancements in technology continue to enhance the performance of these bearings. Innovations such as improved lubrication methods and enhanced surface treatments are being adopted to further reduce energy consumption and improve resistance to environmental factors like dust and moisture. These developments represent the continuous evolution within the bearing industry, attesting to both its expertise and commitment to delivering authoritative solutions for industrial challenges. In conclusion, double cylindrical roller bearings are more than just mechanical components; they are the backbone of high-performance machinery operations across diverse industries. Their proven reliability, backed by expert manufacturing and proper maintenance, assures industries of their operational excellence. Trust in these components is further cemented by the unwavering success they have enabled within industrial applications worldwide. This trust, coupled with ongoing innovations, secures their position as indispensable components in the world of industrial machinery.

When it comes to authority in the bearing sector, numerous OEMs and aftermarket suppliers have established reputations based on expertise with these components. Companies with decades of experience have documented success stories where the deployment of double cylindrical roller bearings has significantly improved operational throughput and machinery reliability. This credence from established industry leaders adds a layer of trustworthiness, as these components are critical in the seamless operation of complex machinery. Real-world applications of double cylindrical roller bearings often showcase their effectiveness in settings that demand robust and reliable operation. In wind turbines, for instance, these bearings support the main rotor shaft, requiring both strength and precision due to the varying loads induced by wind conditions. Similarly, in the steel manufacturing sector, they accommodate the heavy rolling loads found in steel mills, ensuring operational integrity during intense production cycles. Furthermore, advancements in technology continue to enhance the performance of these bearings. Innovations such as improved lubrication methods and enhanced surface treatments are being adopted to further reduce energy consumption and improve resistance to environmental factors like dust and moisture. These developments represent the continuous evolution within the bearing industry, attesting to both its expertise and commitment to delivering authoritative solutions for industrial challenges. In conclusion, double cylindrical roller bearings are more than just mechanical components; they are the backbone of high-performance machinery operations across diverse industries. Their proven reliability, backed by expert manufacturing and proper maintenance, assures industries of their operational excellence. Trust in these components is further cemented by the unwavering success they have enabled within industrial applications worldwide. This trust, coupled with ongoing innovations, secures their position as indispensable components in the world of industrial machinery.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025