júl . 31, 2025 15:59 Vissza a listához

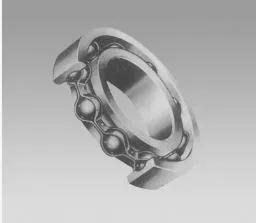

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

The integration of nanotechnology into ball bearing machine components is revolutionizing industries by significantly reducing friction and enhancing durability. This innovation is particularly impactful in gépcsapágyak, mezőgazdasági gépek csapágyai, és ipari gépcsapágyak, where performance and longevity are critical.By incorporating nanomaterials into the manufacturing process, these bearings exhibit enhanced material strength and superior lubrication properties, leading to extended service life. The reduced friction not only boosts efficiency but also decreases wear and tear, ensuring that machinery operates smoothly over extended periods. This technological advancement underscores the commitment to delivering cutting-edge solutions that meet the rigorous demands of modern industrial applications.

The Role of Nanotechnology in Machinery Csapágyak Csapágyak

Nanotechnology is transforming ball mill bearing designs by introducing advanced materials and coatings that minimize wear and tear. Here’s how:

l Enhanced Material Strength

Nanostructured alloys and ceramics are being used in gépcsapágyak to improve load capacity and resistance to deformation. These materials ensure smoother operation even under extreme conditions, making them ideal for ipari gépcsapágyak.

l Superior Lubrication Properties

Nanocoatings reduce friction by creating ultra-smooth surfaces on ball bearing machine components. This innovation is especially beneficial for mezőgazdasági gépek csapágyai, where dust and debris often compromise traditional lubrication.

l Extended Service Life

By minimizing friction and wear, nanotechnology extends the lifespan of ball mill bearing units. This reduces maintenance costs and downtime, offering long-term savings for industries relying on heavy-duty gépcsapágyak.

Applications Across Industries: Machinery Csapágyak

From agriculture to manufacturing, nanotechnology-enhanced bearings are making waves.

l Agricultural Machinery Bearings

In farming equipment, mezőgazdasági gépek csapágyai must withstand harsh environments. Nanotech coatings protect against corrosion and abrasion, ensuring reliable performance in tractors, harvesters, and other machinery.

l Industrial Machine Bearings

Factories depend on ipari gépcsapágyak for seamless operations. Nanostructured materials enhance precision and reduce energy consumption, making them indispensable in high-speed applications.

l Ball Mill Bearings

Mining and cement industries rely on ball mill bearing systems for grinding operations. Nanotech improvements boost efficiency and reduce heat generation, optimizing productivity.

Comparing Traditional Bearings vs. Nanotech-Enhanced Bearings

The advancement of nanotechnology has significantly improved bearing performance. Below is a comparison between traditional bearings and nanotech-enhanced gépcsapágyak:

|

Feature |

Traditional Bearings |

Nanotech-Enhanced Bearings |

|

Súrlódáscsökkentés |

Moderate, requires frequent lubrication |

Ultra-low, self-lubricating due to nanocoatings |

|

Tartósság |

Prone to wear under heavy loads |

Exceptional wear resistance, longer lifespan |

|

Korrózióállóság |

Susceptible to rust in harsh environments |

Highly resistant due to nanostructured materials |

|

Maintenance Needs |

Regular lubrication & replacement |

Minimal maintenance, reduced downtime |

|

Applications |

General industrial use |

High-performance industrial machine bearings, agricultural machinery bearings, and ball mill bearing systems |

l Improved Efficiency in Ball Bearing Machine Components

Nanotech bearings reduce energy loss, making them ideal for high-speed gépcsapágyak in manufacturing and processing plants.

l Cost-Effectiveness Over Time

While initial costs may be higher, nanotech-enhanced mezőgazdasági gépek csapágyai save money by reducing replacement frequency and maintenance expenses.

l Adaptability to Extreme Conditions

From high-temperature environments to corrosive settings, nanotech ipari gépcsapágyak outperform traditional options, ensuring reliability in critical applications.

This comparison highlights why industries are rapidly adopting nanotechnology in ball mill bearing and other high-demand bearing systems. For wholesalers, stocking these advanced solutions means offering customers cutting-edge performance and long-term savings. Explore ARY Bearing’s catalog today for premium nanotech-enhanced bearings!

Why Choose Machinery Csapágyak from ARY Bearing's Advanced Solutions?

ARY Bearing offers cutting-edge gépcsapágyak designed for superior performance.

l Unmatched Durability

Our ipari gépcsapágyak incorporate nanotechnology for unmatched wear resistance, ensuring longevity even in the toughest conditions.

l Precision Engineering

Every ball bearing machine component from ARY Bearing is crafted with precision, guaranteeing smooth operation and minimal energy loss.

l Custom Solutions

We provide tailored mezőgazdasági gépek csapágyai és ball mill bearing units to meet specific industry needs, backed by expert support.

FAQ:About Machinery Csapágyak

What makes machinery bearings superior?

Nanotech coatings reduce friction and wear, enhancing efficiency and lifespan in gépcsapágyak.

Are machinery bearings suitable for heavy-duty applications?

Yes, our ipari gépcsapágyak are designed to handle extreme loads and harsh environments.

How do nanotech mezőgazdasági gépek csapágyai perform in dusty conditions?

They feature self-lubricating properties that prevent contamination, ensuring reliable performance.

Can ARY machinery bearings customize ball mill bearing solutions?

Absolutely! We offer tailored designs to meet specific operational requirements.

Where can wholesalers order these advanced machinery bearings?

Visit ARY Bearing to explore our range and place bulk orders for high-performance gépcsapágyak.

Nanotechnology is redefining the future of ball bearing machine systems, offering unparalleled benefits across industries. For wholesalers seeking top-tier ipari gépcsapágyak, mezőgazdasági gépek csapágyai, és ball mill bearing solutions, ARY Bearing is the trusted partner. Place your order today and experience the next generation of friction reduction!Our team of experts leverages cutting-edge nanotechnology to tailor bespoke bearing solutions that cater to the unique requirements of various industries. Whether you need bearings for heavy-duty machinery, precision equipment, or high-speed applications, we have the expertise to deliver tailored solutions that optimize performance and reliability. With ARY Bearing, you can be assured of receiving custom-made bearings that meet your exact specifications, ensuring maximum efficiency and durability in your operations.

Legfrissebb hírek

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

HírNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

HírNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

HírNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

HírNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

HírNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

HírNov.22,2025