Nov . 23, 2024 08:41 Back to list

cylindrical ball bearing

The Importance of Cylindrical Ball Bearings in Modern Engineering

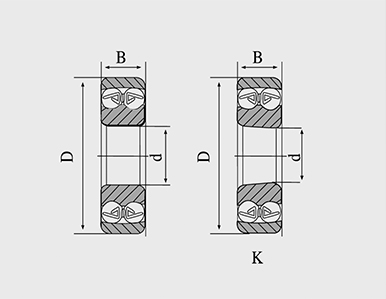

Cylindrical ball bearings are essential components in various mechanical systems, playing a critical role in reducing friction and facilitating smooth rotation. These bearings consist of an inner ring, an outer ring, rolling elements (cylindrical balls), and typically a cage to provide spacing between the rolling elements. Their design allows them to accommodate both radial and axial loads, making them versatile and widely used in numerous applications.

Design and Functionality

The fundamental purpose of a cylindrical ball bearing is to support rotating shafts and reduce the friction that occurs between moving parts. The smooth surface of the balls allows for a near-frictionless movement, which is crucial in high-speed applications. The cylindrical shape of the rolling elements enables the bearings to distribute loads evenly, providing stability and longevity to machinery.

The materials used to manufacture cylindrical ball bearings are crucial for their performance. Most commonly, they are made from high-quality steel or ceramic materials. Steel bearings are known for their strength and durability, while ceramic bearings offer advantages in terms of weight and resistance to corrosion and heat. The choice of material often depends on the specific application, operating environment, and expected load conditions.

Applications

Cylindrical ball bearings are widely used across various industries, including automotive, aerospace, manufacturing, and robotics. In the automotive sector, these bearings can be found in engines, transmissions, and wheels, where they help to ensure efficient operation and enhance the lifespan of the components. In aerospace, the reliability and lightweight properties of cylindrical bearings are critical for flight safety and performance.

cylindrical ball bearing

Moreover, these bearings are also integral to industrial machinery such as conveyor systems, pumps, and electric motors. They allow for efficient motion in automated systems, minimizing downtime and maintenance needs. With the rise of robotics and automation, the demand for high-performance cylindrical ball bearings continues to grow, emphasizing their importance in modern engineering.

Advantages

One of the primary advantages of cylindrical ball bearings is their ability to handle both radial and axial loads. This versatility makes them ideal for applications where space is limited, and weight is a concern. Additionally, the use of high-quality materials and advanced manufacturing techniques contributes to their durability and reliability, ensuring they can withstand challenging operating conditions.

Cylindrical ball bearings are also relatively easy to install and maintain. Regular inspection and lubrication can significantly extend their service life and enhance their performance. The ability to provide smooth, low-friction movement makes them invaluable in enhancing the efficiency of mechanical systems.

Conclusion

In conclusion, cylindrical ball bearings are a foundational component in the realm of mechanical engineering. Their unique design, versatility, and reliability contribute to their widespread use across numerous industries. As technology continues to advance, the development of more efficient and durable cylindrical ball bearings will remain vital to the improvement of machinery and the optimization of performance in various applications. Their importance cannot be overstated, as they are key players in the machinery that drives our modern world.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025