Jul . 31, 2025 15:56 צוריק צו דער ליסטע

How Deep Groove Ball Bearings Are Tailored for Different Uses

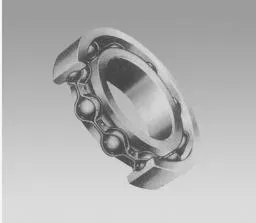

Deep groove ball bearings are versatile components that play a crucial role in various industrial applications, ensuring smooth and efficient operation. By understanding the deep groove ball bearing specification, types, uses, and sizes, we can appreciate how these bearings are customized to meet the specific demands of different industries. This article delves into the intricacies of טיף גרוב קוגל בערינגז, highlighting their unique characteristics and how they are tailored for optimal performance in diverse settings.

Understanding Deep Groove Ball Bearings

Deep groove ball bearings are designed with a unique deep groove ball bearing specification that allows them to handle both radial and axial loads effectively. The raceway on the inner and outer rings has a radius slightly larger than the ball’s radius, enabling smooth load distribution. These bearings come in various types, including open, shielded, and sealed variants, each offering different levels of protection against contaminants. For instance, the open type allows for easy inspection and maintenance, while the shielded and sealed types provide better protection against dust and moisture.

- Applications Across Industries

די uses of deep groove ball bearings are extensive, spanning multiple industries such as automotive, machinery, aerospace, and more. In the automotive sector, these bearings are used in wheel hubs, steering systems, and transmission systems, ensuring smooth and reliable operation. In machinery, they are found in electric motors, gearboxes, and conveyor systems, contributing to high-speed rotation and low noise levels. Their ability to handle both radial and axial loads makes them suitable for a wide range of applications.

- Sizing and Dimensions

When it comes to deep groove ball bearing sizes, there is a wide variety to choose from, catering to different load requirements and operational speeds. The dimensions include the outer diameter (D), inner diameter (d), and width (B), among others. For example, the 6011-RZ bearing has an outer diameter of 90 mm, an inner diameter of 55 mm, and a width of 18 mm. The basic load rating and limiting speeds also vary among models, with the 6011-RZ having a basic load rating of 30.3 kN and a limiting speed of 7000 rpm for grease lubrication.

Tailoring Performance מיט טיף גרוב פּילקע בערינגז

In high-speed applications, טיף גרוב קוגל בערינגז are customized to ensure minimal friction and maximum efficiency. These bearings are designed with low friction torque, making them ideal for applications that require high-speed rotation, low noise, and low vibration. The use of steel plate stamped cages and the precise engineering of the raceway contribute to their high performance. For example, the 6012 bearing has a limiting speed of 6700 rpm for grease lubrication, showcasing its suitability for high-speed operations.

- Enhancing Load Capacity

For applications that involve heavy loads, טיף גרוב קוגל בערינגז are tailored to handle significant radial and axial loads. By increasing the radial clearance, these bearings can even replace high-speed angular contact ball bearings in certain scenarios. This makes them a versatile choice for applications where both types of loads are present. However, it is important to note that bearings with notches are not suitable for carrying axial loads.

- Improving Durability and Protection

To enhance durability and protect against contaminants, טיף גרוב קוגל בערינגז come with various protective features. These include steel plate dust covers, rubber sealing rings, and stop rings attached to the outer diameter of the outer ring. These features not only protect the bearing from dust and moisture but also reduce the need for frequent maintenance, ensuring long-term reliability.

Comparative Analysis of Deep Groove Ball Bearings

To further illustrate the customization and performance capabilities of טיף גרוב קוגל בערינגז, let's examine a comparative table of various models and their key performance metrics. This table highlights the differences in dimensions, load ratings, and limiting speeds, which are crucial factors in selecting the right bearing for specific applications.

|

Model Number |

Dimension (mm) |

Basic Load Rating (kN) |

Limiting Speed (rpm) |

Remarks |

|

6011-RZ |

90 x 55 x 18 |

30.3 |

7000 |

Suitable for moderate loads and high-speed applications |

|

6012 |

95 x 60 x 18 |

31.7 |

6700 |

Ideal for high-speed and low-noise applications |

|

6013 |

100 x 65 x 18 |

32.1 |

6300 |

High load capacity with moderate speed |

|

6014 |

110 x 70 x 20 |

38.6 |

5700 |

Heavy load applications with lower speed |

|

6015 |

115 x 75 x 20 |

40.2 |

5400 |

High load capacity with moderate speed |

|

6016 |

125 x 80 x 22 |

47.5 |

5000 |

Suitable for high-speed applications with significant axial loads |

|

6017 |

130 x 85 x 22 |

50.8 |

4500 |

High load capacity with moderate speed |

|

6018 |

140 x 90 x 24 |

57.5 |

4300 |

Heavy load applications with lower speed |

This table demonstrates the wide range of deep groove ball bearing sizes and their corresponding performance capabilities. Each model is tailored to meet specific load and speed requirements, making them suitable for various industrial applications. For example, the 6012 model is ideal for applications requiring high speed and low noise, while the 6014 model is better suited for heavy load applications with lower speed requirements.

FAQ:About טיף גרוב פּילקע בערינגז

What are the advantages of deep groove ball bearings?

Deep groove ball bearings offer several advantages, including their ability to handle both radial and axial loads, low friction, and high-speed capabilities. They are also available in a wide range of sizes and types, making them suitable for various applications.

How do I choose the right deep groove ball bearing for my application?

When choosing a deep groove ball bearing, consider factors such as load requirements, speed, noise and vibration levels, and operating environment. Refer to the specifications and dimensions provided by the manufacturer to ensure the bearing meets your needs.

What is the difference between open and sealed deep groove ball bearings?

Open טיף גרוב קוגל בערינגז allow for easy inspection and maintenance but may require additional protection against contaminants. Sealed bearings, on the other hand, are protected against dust and moisture, reducing the need for frequent maintenance.

Can deep groove ball bearings be used in high-temperature applications?

While טיף גרוב קוגל בערינגז are generally suitable for a wide range of temperatures, their performance may vary depending on the specific application. It is important to choose the appropriate lubricant and materials to ensure optimal performance in high-temperature environments.

Where can I purchase high-quality deep groove ball bearings?

You can purchase high-quality טיף גרוב קוגל בערינגז from reputable suppliers like ARYBEARING. They offer a wide range of bearings with detailed specifications and competitive prices. Visit their website to explore their product offerings and place your order.

Deep groove ball bearings are highly versatile and customizable components that are tailored to meet the specific needs of various applications. From high-speed operations to heavy-load scenarios, these bearings offer reliable performance and durability. We encourage wholesalers to promote these high-quality bearings and invite everyone to order from our company to ensure optimal performance in their applications. Whether you need bearings for automotive, machinery, or other industrial uses, טיף גרוב קוגל בערינגז are designed to deliver exceptional results.

לעצטע נייעס

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

נייעסNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

נייעסNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

נייעסNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

נייעסNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

נייעסNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

נייעסNov.22,2025