Oct . 18, 2024 14:03 Back to list

Guide to Installing Tapered Roller Bearings for Optimal Performance and Longevity

Installing Tapered Roller Bearings A Comprehensive Guide

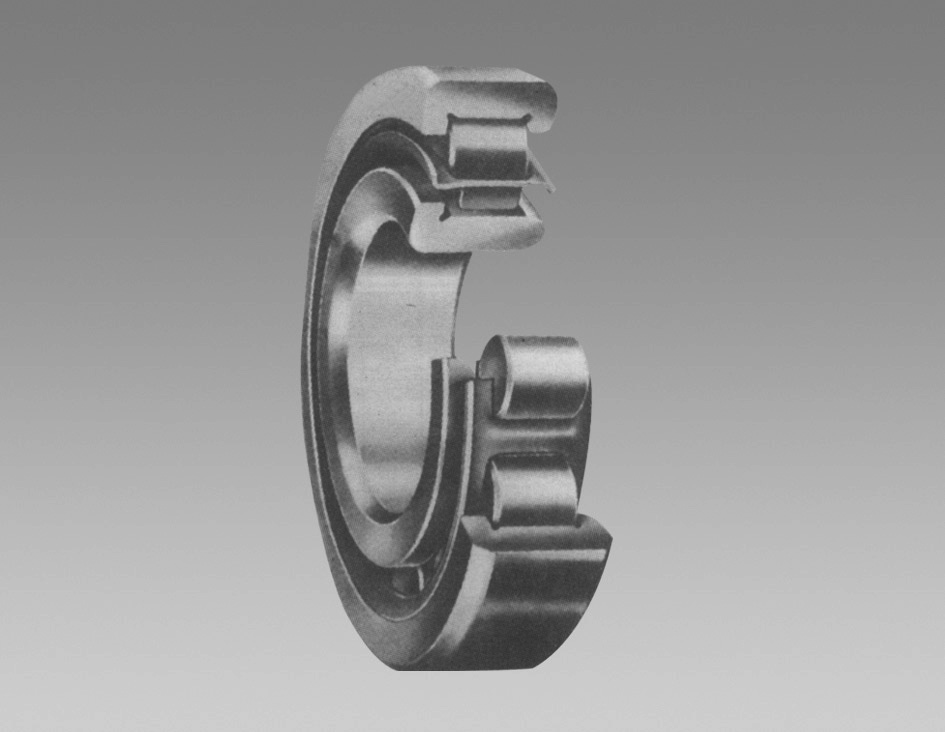

Tapered roller bearings are designed to carry both radial and axial loads, making them a critical component in various applications, including automotive, industrial machinery, and aerospace systems. Proper installation is crucial for ensuring the longevity and performance of these bearings. In this article, we will explore the essential steps and considerations involved in installing tapered roller bearings.

Understanding Tapered Roller Bearings

Tapered roller bearings consist of an inner ring, an outer ring, rolling elements (usually tapered rollers), and a cage. The tapered shape allows the rollers to maintain contact with the raceway, enabling the bearing to accommodate both axial and radial loads. This makes them exceptionally versatile, but it also means that installation needs to be carried out with precision.

Tools and Preparation

Before you begin the installation process, gather the necessary tools, which may include

- A bearing puller - Torque wrench - Calipers or micrometers - Mallet or hammer - Press (for interference fits) - Clean cloths and appropriate lubricant

Ensure that the work area is clean to avoid contamination, which is a common cause of premature bearing failure

.Step-by-Step Installation Process

1. Inspect the Bearings and Housing Before installation, thoroughly inspect the bearings and their housing for signs of damage or wear. Check that the surfaces are clean and free of debris. Any imperfections can lead to failure.

installing tapered roller bearings

2. Prepare the Housing If applicable, heat the bearing outer ring slightly (to about 100°C or 212°F) to facilitate easier installation. You can use a bearing heater or an oven. This thermal expansion will allow the bearing to fit easily into the housing.

3. Install the Outer Race Gently place the heated outer race into the housing. Ensure that it is aligned properly; an incorrect alignment can cause undue stress on the bearing.

4. Condition the Inner Race The inner race can also be heated if necessary, particularly if it fits tightly on the shaft. However, this is often not required. If the fit is appropriate, place the inner race onto the shaft.

5. Insert Rollers Once both races are in place, you can begin inserting the tapered rollers. Be sure to place them in the correct orientation, where the large ends of the rollers are facing the larger diameter of the raceways. Use a clean lubricant to coat the rollers lightly, reducing friction during operation.

6. Install the Cage After properly seated the rollers, install the cage that holds the rollers in position. This helps maintain proper spacing and alignment between the rollers, which is crucial for optimal performance.

7. Completing the Installation Once the bearings are assembled, ensure everything is tight. You can use a torque wrench to tighten any associated fasteners to the recommended specifications. This step is critical to prevent movement that could cause premature wear or failure.

8. Final Inspection After installation, conduct a final inspection to ensure that all components are properly aligned and secured. Rotate the assembly by hand to check for smooth operation without any binding or noise.

Conclusion

Installing tapered roller bearings may seem daunting, but with careful preparation and attention to detail, the process can be effectively managed. Proper installation not only enhances the performance and lifespan of the bearings but also contributes to the overall efficiency of the equipment they are a part of. Always refer to the manufacturer’s guidelines for specific torque values and additional instructions for your particular application. By following these steps, you can ensure a reliable and successful installation of tapered roller bearings.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025