Dec . 18, 2024 14:53 Back to list

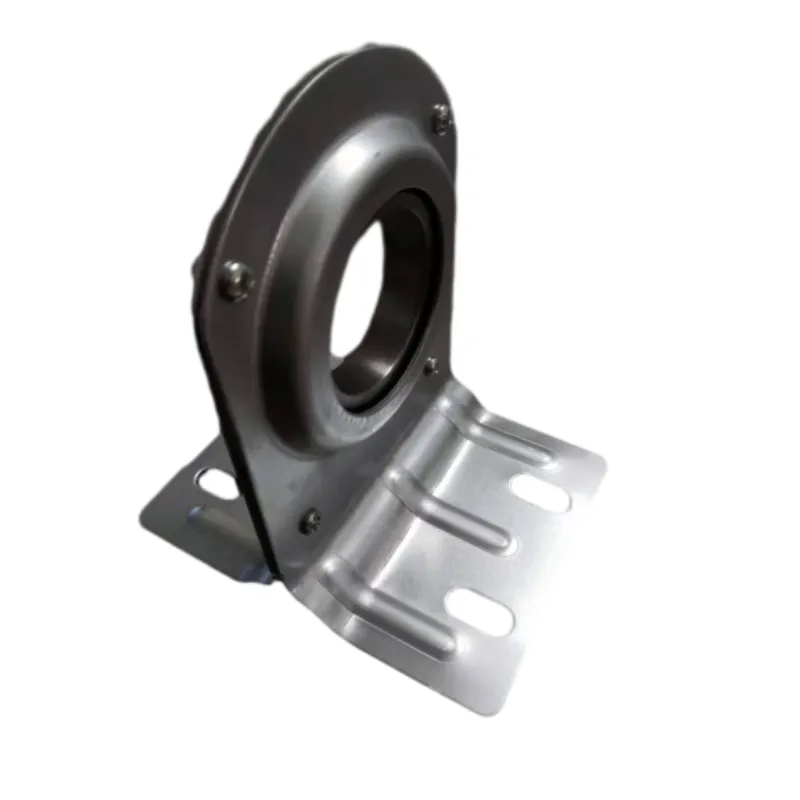

22328 bearing

Understanding the 22328 Bearing Key Characteristics and Applications

Bearings are crucial components in the machinery and mechanical systems that power our modern world. At the heart of many machines, the bearing facilitates rotational or linear motion while minimizing friction between moving parts. Among various types of bearings, the 22328 bearing stands out due to its distinct design and application benefits. This article explores the characteristics, applications, and maintenance considerations of the 22328 bearing.

What is the 22328 Bearing?

The 22328 bearing is categorized as a spherical roller bearing. Spherical roller bearings are designed to accommodate misalignment and provide axial as well as radial load support. The designation 22328 indicates its specific dimensions and load capacities. The term 20 often refers to the series type or internal design features. Given its robust construction, the 22328 bearing can endure high loads and is particularly renowned for its self-aligning capabilities.

One of the hallmark features of the 22328 bearing is its ability to accommodate substantial angular misalignment due to its spherical interior shape, which allows the rolling elements to adjust their position relative to the outer ring. This is critical in applications where shafts may not be perfectly aligned, preventing unnecessary wear and failure of the bearing.

Technical Specifications

The 22328 bearing generally exhibits a dynamic load rating of around 164 kN and a static load rating ranging from 150 kN, depending on the manufacturer. With an outer diameter of 280 mm and an inner diameter of 140 mm, it is capable of supporting heavy loads while maintaining minimal noise and vibration levels. The cage material, typically steel or brass, enhances durability and performance under varying operating conditions.

Lubrication is vital for the longevity and efficient functioning of the 22328 bearing. Grease or oil lubrication helps reduce friction and removes heat generated from contact surfaces during rotation. Therefore, selecting the right lubricant is essential, taking into account factors such as load, speed, and environmental conditions.

22328 bearing

Applications of 22328 Bearing

The versatility of the 22328 bearing makes it suitable for various industries. It is frequently utilized in heavy machinery, such as crushers, conveyor systems, and industrial fans, where heavy radial loads are common. Additionally, it finds applications in the construction and mining sectors, powering equipment like excavators and drilling rigs.

Moreover, the automotive sector employs the 22328 bearing in components such as gearboxes and axles, where reliability and high load capacity are paramount. Its self-aligning feature reduces the risk of failure due to shaft misalignment, making it ideal for applications where precision is critical.

Maintenance Considerations

To ensure the effective performance of the 22328 bearing, regular maintenance is essential. Users should implement a routine inspection schedule to check for wear and tear, especially in high-load applications. Detecting early signs of failure, such as unusual noise or vibrations, can prevent catastrophic breakdowns and reduce downtime.

Proper lubrication maintenance is another critical aspect. Over-greasing or under-greasing can lead to overheating or insufficient lubrication, respectively. Hence, adhering to the manufacturer’s specifications for lubrication intervals and amounts is crucial.

Conclusion

The 22328 bearing exemplifies the perfect blend of strength and versatility in bearing technology. Its unique structural features make it an ideal choice for a broad range of applications, particularly in heavy machinery and automotive sectors. Understanding its specifications, applications, and maintenance tips ensures that users maximize its performance and lifespan. In a world that relies heavily on machinery and efficiency, the 22328 bearing remains an indispensable component with significant contributions to operational excellence. With proper application and care, it can effectively withstand the demands of modern industrial environments.

Latest news

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025