Fev . 16, 2025 10:54 Back to list

Spherical Roller Bearings

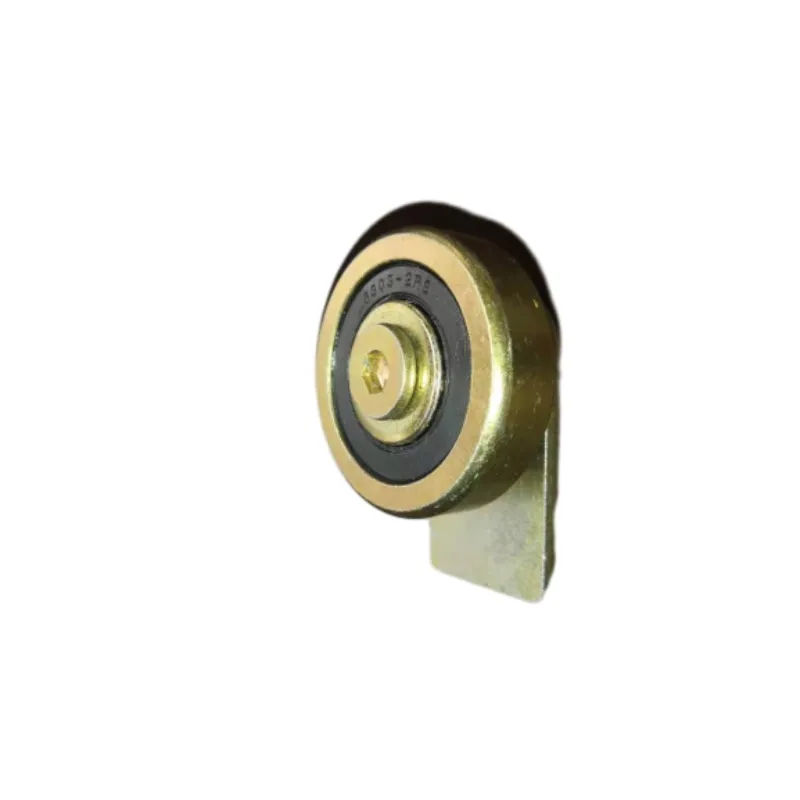

The realm of double row deep groove ball bearings is one that melds precision engineering with intricate dynamics, making it a focal point in industrial applications where both load capacity and durability are paramount. These bearings are uniquely designed to manage radial and axial loads in both directions, which distinguishes them from their single-row counterparts. This article delves into the intricacies surrounding the sizing and selection of double row deep groove ball bearings, providing insights grounded in industry experience and expertise.

The precision in manufacturing these components can't be overstated. Double row deep groove ball bearings are crafted to exacting standards, often specified by global benchmarks such as ISO or ANSI. These standards ensure that regardless of the application or location, the bearings perform consistently and reliably, instilling confidence across industries. Experienced engineers emphasize not only size and load capacity but also the importance of material selection and sealing techniques, which are pivotal in extending bearing lifespan. From an authoritative standpoint, established manufacturers like SKF, NSK, and FAG have significantly contributed to the proliferation of knowledge regarding these bearings. Their research and development divisions work tirelessly to innovate and refine bearing technologies, ensuring that they meet the ever-evolving demands of modern engineering challenges. Publications and technical bulletins from such entities become vital resources for professionals seeking to deepen their understanding and application of these components. Trust in double row deep groove ball bearings also hinges on the maintenance practices employed once they are installed. Regular inspection, lubrication, and monitoring of operational conditions are critical aspects that ensure these bearings achieve their maximum service life. Technicians and operators are often trained specifically in bearing management, further contributing to the reliability and trustworthiness of these bearings in critical applications. In summary, the depth of expertise required to effectively utilize double row deep groove ball bearings underscores their complexity and importance. By leveraging detailed size charts and adhering to the best practices in selection, installation, and maintenance, industries can harness the full potential of these remarkable components. The intersection of engineering acumen, manufacturing excellence, and practical application positions these bearings as fundamental enablers of efficiency and reliability across a multitude of sectors.

The precision in manufacturing these components can't be overstated. Double row deep groove ball bearings are crafted to exacting standards, often specified by global benchmarks such as ISO or ANSI. These standards ensure that regardless of the application or location, the bearings perform consistently and reliably, instilling confidence across industries. Experienced engineers emphasize not only size and load capacity but also the importance of material selection and sealing techniques, which are pivotal in extending bearing lifespan. From an authoritative standpoint, established manufacturers like SKF, NSK, and FAG have significantly contributed to the proliferation of knowledge regarding these bearings. Their research and development divisions work tirelessly to innovate and refine bearing technologies, ensuring that they meet the ever-evolving demands of modern engineering challenges. Publications and technical bulletins from such entities become vital resources for professionals seeking to deepen their understanding and application of these components. Trust in double row deep groove ball bearings also hinges on the maintenance practices employed once they are installed. Regular inspection, lubrication, and monitoring of operational conditions are critical aspects that ensure these bearings achieve their maximum service life. Technicians and operators are often trained specifically in bearing management, further contributing to the reliability and trustworthiness of these bearings in critical applications. In summary, the depth of expertise required to effectively utilize double row deep groove ball bearings underscores their complexity and importance. By leveraging detailed size charts and adhering to the best practices in selection, installation, and maintenance, industries can harness the full potential of these remarkable components. The intersection of engineering acumen, manufacturing excellence, and practical application positions these bearings as fundamental enablers of efficiency and reliability across a multitude of sectors.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025