Фев . 17, 2025 14:58 Back to list

Deep Groove Ball Bearings

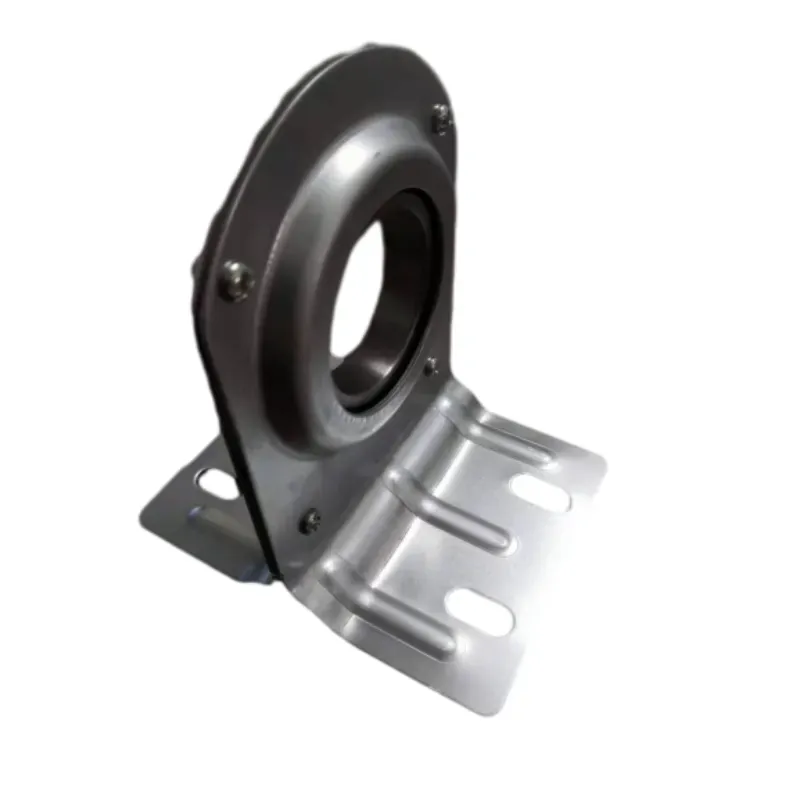

Deep groove ball bearings, often heralded as the backbone of countless mechanical applications, are indispensable in industries ranging from automotive to aerospace. Their ability to handle both radial and axial loads, combined with low friction, makes them a preferred choice for manufacturers seeking reliability and efficiency. As an expert in this domain, it is essential to delve into the intricacies of these components to truly understand their unparalleled value.

Trustworthiness in companies that produce these bearings comes from years of expertise and commitment to quality. Renowned manufacturers adhere to international standards, such as ISO and ABEC ratings, ensuring that the bearings provide consistent performance over time. In addition to the traditional uses, today's deep groove ball bearings are pivotal in green technology. Wind turbines, for instance, rely on these components for their ability to operate under variable loads and conditions without compromising efficiency. This enhances the reliability of renewable energy sources, contributing to sustainability efforts globally. Real-world experiences advocate for routine inspection and maintenance of deep groove ball bearings to prevent unexpected downtime. Users report that adherence to manufacturer guidelines and periodic lubrication significantly extends the service life of the bearings, enhancing the overall performance of the machinery. Finally, it's essential to highlight the economic aspect. Cost-effectiveness is a notable advantage of deep groove ball bearings. Their long lifespan, coupled with minimal maintenance, translates to reduced operational costs. Furthermore, the ease of installation streamlines assembly processes, adding an extra layer of efficiency. In conclusion, deep groove ball bearings epitomize the perfect blend of engineering excellence and practical application. Their robustness and reliability continue to support a myriad of industries, bolstered by the expertise and trustworthiness of manufacturers dedicated to innovation and quality. Their role in ensuring efficient mechanical operations makes them an irreplaceable component in modern machinery, underscoring their importance in today's technological landscape.

Trustworthiness in companies that produce these bearings comes from years of expertise and commitment to quality. Renowned manufacturers adhere to international standards, such as ISO and ABEC ratings, ensuring that the bearings provide consistent performance over time. In addition to the traditional uses, today's deep groove ball bearings are pivotal in green technology. Wind turbines, for instance, rely on these components for their ability to operate under variable loads and conditions without compromising efficiency. This enhances the reliability of renewable energy sources, contributing to sustainability efforts globally. Real-world experiences advocate for routine inspection and maintenance of deep groove ball bearings to prevent unexpected downtime. Users report that adherence to manufacturer guidelines and periodic lubrication significantly extends the service life of the bearings, enhancing the overall performance of the machinery. Finally, it's essential to highlight the economic aspect. Cost-effectiveness is a notable advantage of deep groove ball bearings. Their long lifespan, coupled with minimal maintenance, translates to reduced operational costs. Furthermore, the ease of installation streamlines assembly processes, adding an extra layer of efficiency. In conclusion, deep groove ball bearings epitomize the perfect blend of engineering excellence and practical application. Their robustness and reliability continue to support a myriad of industries, bolstered by the expertise and trustworthiness of manufacturers dedicated to innovation and quality. Their role in ensuring efficient mechanical operations makes them an irreplaceable component in modern machinery, underscoring their importance in today's technological landscape.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025