Feb . 17, 2025 12:45 Back to list

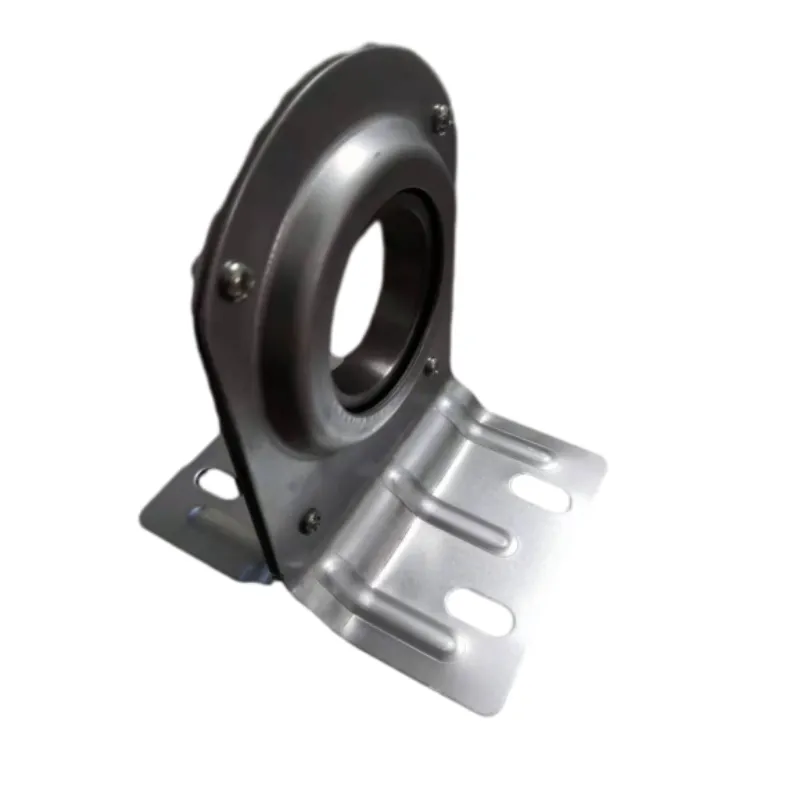

Deep Groove Ball Bearings

Understanding and selecting the right single row deep groove bearings can significantly influence machinery performance and resource efficiency. These bearings are not only pivotal in reducing friction and supporting radial and axial loads but also in optimizing the smooth operation of various mechanical applications.

In terms of innovation, companies specializing in the manufacture of single row deep groove bearings are increasingly incorporating advanced materials and manufacturing techniques. Utilizing ceramic balls in lieu of steel is one such innovation aimed at enhancing speed performance and reducing thermal expansion issues. These ceramics are lighter, harder, and more resistant to extreme temperatures, rendering them ideal for high-performance applications. Industry leaders in bearing technology continually invest in research and development to ensure their products meet evolving industrial demands. This emphasis on innovation underscores their commitment to delivering products that offer superior performance and reliability. Consumers seeking dependable products should consider manufacturers renowned for their expertise and precision engineering. Trustworthiness in selecting the right supplier is paramount. It’s advisable to collaborate with manufacturers that adhere to international quality standards such as ISO 9001 and have a proven track record of customer satisfaction. Reviews, testimonials, and case studies can provide valuable insights into a manufacturer’s reliability and the performance of their products. In summary, single row deep groove bearings are integral components that play a crucial role in a multitude of applications. Selecting high-quality bearings tailored to specific operational requirements can greatly enhance machinery efficiency and longevity. By focusing on expertise, quality standards, and innovation, businesses can ensure the reliability and success of their mechanical operations.

In terms of innovation, companies specializing in the manufacture of single row deep groove bearings are increasingly incorporating advanced materials and manufacturing techniques. Utilizing ceramic balls in lieu of steel is one such innovation aimed at enhancing speed performance and reducing thermal expansion issues. These ceramics are lighter, harder, and more resistant to extreme temperatures, rendering them ideal for high-performance applications. Industry leaders in bearing technology continually invest in research and development to ensure their products meet evolving industrial demands. This emphasis on innovation underscores their commitment to delivering products that offer superior performance and reliability. Consumers seeking dependable products should consider manufacturers renowned for their expertise and precision engineering. Trustworthiness in selecting the right supplier is paramount. It’s advisable to collaborate with manufacturers that adhere to international quality standards such as ISO 9001 and have a proven track record of customer satisfaction. Reviews, testimonials, and case studies can provide valuable insights into a manufacturer’s reliability and the performance of their products. In summary, single row deep groove bearings are integral components that play a crucial role in a multitude of applications. Selecting high-quality bearings tailored to specific operational requirements can greatly enhance machinery efficiency and longevity. By focusing on expertise, quality standards, and innovation, businesses can ensure the reliability and success of their mechanical operations.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025