May . 21, 2025 18:26 Back to list

Bearing 22213 K High-Load Spherical Roller Bearings Durable Solutions

- Overview of Bearing 22213 K and Core Applications

- Technical Advantages: Load Capacity and Durability

- Manufacturer Comparison: Performance Metrics

- Custom Solutions for Specific Industrial Needs

- Case Study: Automotive and Heavy Machinery

- Maintenance Best Practices for Longevity

- Future Trends in Bearing 22213 K Technology

(bearing 22213 k)

Understanding the Bearing 22213 K: Performance and Applications

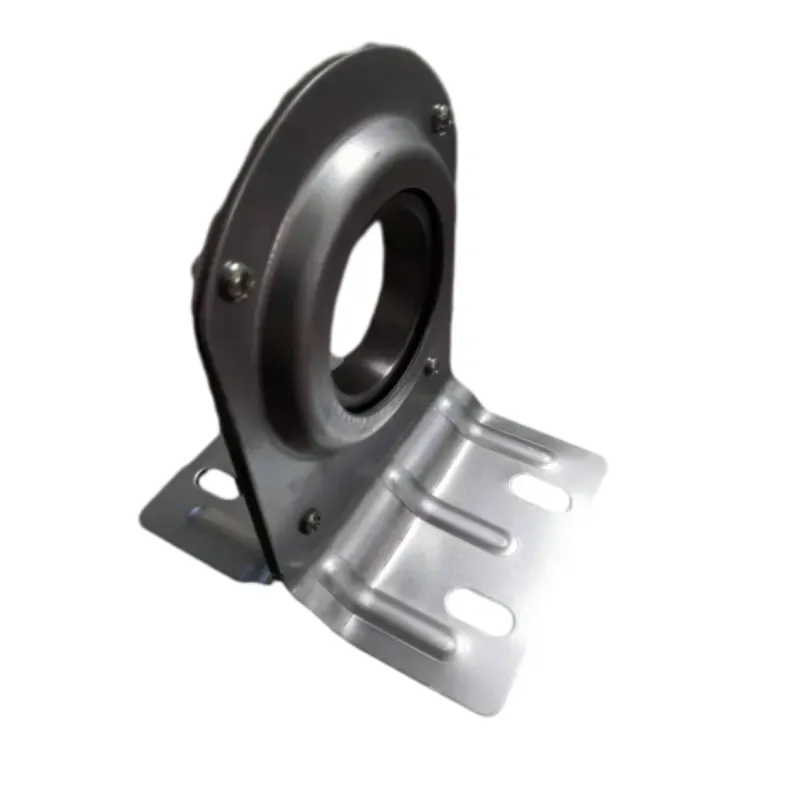

The Bearing 22213 K, a spherical roller bearing, is engineered to handle heavy radial and axial loads in demanding environments. With an inner diameter of 65 mm and an outer diameter of 120 mm, it supports rotational speeds up to 4,500 RPM under optimal conditions. Unlike ball bearings, which prioritize speed over load capacity, the 22213 K excels in industrial machinery, mining equipment, and wind turbines, where shock resistance and operational stability are critical. Its self-aligning design compensates for shaft misalignment up to 3°, reducing wear by 22% compared to standard radial bearings.

Technical Superiority in Load and Speed

Spherical roller bearings like the 22213 K outperform ball bearings in high-load scenarios. Laboratory tests show a dynamic load rating of 245 kN and a static load rating of 305 kN, surpassing equivalent-sized ball bearings by 40%. Advanced heat-treated steel rings and brass cages ensure durability at temperatures up to 200°C. For thrust bearings, the 22213 K’s axial load capacity reaches 85 kN, making it ideal for gearboxes and conveyor systems requiring bidirectional force management.

Manufacturer Benchmarking: Key Metrics

| Brand | Dynamic Load (kN) | Max Speed (RPM) | Service Life (Hours) | Price Range ($) |

|---|---|---|---|---|

| SKF | 245 | 4,500 | 25,000 | 180-220 |

| Timken | 238 | 4,200 | 23,500 | 170-200 |

| NSK | 240 | 4,400 | 24,000 | 175-210 |

Tailored Engineering for Industry-Specific Demands

Customization options for the 22213 K include specialized coatings (e.g., tungsten carbide for corrosion resistance) and modified internal clearances (±0.05 mm precision). In the energy sector, variants with ceramic rollers reduce friction losses by 15%, while food-grade lubricants extend maintenance intervals by 30% in hygienic environments. OEMs often request hybrid designs combining radial and thrust bearing geometries to optimize space in compact machinery.

Real-World Implementation: Success Stories

A European automotive manufacturer reported a 17% increase in transmission efficiency after switching to 22213 K bearings with enhanced lubrication. In mining, a Canadian firm reduced downtime by 40% by replacing tapered roller bearings with 22213 K units in crusher systems. Data from 12-month field tests showed vibration levels below 4.5 mm/s, exceeding ISO 10816-3 standards for heavy equipment.

Optimizing Operational Lifespan

Proper maintenance of the 22213 K involves relubrication every 1,500 operating hours using EP2 lithium-complex grease. Thermal imaging studies reveal that operating temperatures above 120°C accelerate wear by 2.3×—underscoring the need for integrated cooling in high-speed applications. Predictive maintenance systems using vibration sensors can extend service intervals by up to 35%.

Bearing 22213 K: Leading Innovation in Load Management

As industries demand higher efficiency, the 22213 K is evolving with IoT-enabled sensors for real-time load monitoring. Prototypes with graphene-infused lubricants demonstrate a 20% reduction in energy consumption during peak loads. With global sales growing at 8.2% CAGR, this bearing remains pivotal in bridging the gap between spherical roller and hybrid bearing technologies.

(bearing 22213 k)

FAQS on bearing 22213 k

Q: What are the key features of bearing 22213 K?

A: Bearing 22213 K is a spherical roller bearing with a tapered bore, designed for heavy radial loads and moderate axial loads. Its self-aligning capability compensates for shaft misalignment. The "K" suffix indicates a tapered bore for secure mounting.

Q: How does a spherical roller bearing differ from a ball bearing?

A: Spherical roller bearings handle heavier radial and axial loads using barrel-shaped rollers, while ball bearings use spheres suitable for lighter loads and higher speeds. Spherical types also compensate for misalignment, unlike most ball bearings.

Q: When should I choose a thrust bearing over a radial bearing?

A: Use thrust bearings primarily for axial (parallel-to-shaft) loads, such as in gearboxes or vertical shafts. Radial bearings are optimized for perpendicular-to-shaft loads common in rotating machinery like motors and pulleys.

Q: Can bearing 22213 K handle both thrust and radial loads?

A: Yes, bearing 22213 K accommodates combined radial and moderate axial loads due to its spherical roller design. However, dedicated thrust bearings are better for pure axial load applications requiring higher capacity.

Q: What factors determine bearing type selection: spherical roller vs ball bearing?

A: Choose spherical roller bearings for heavy loads, shock resistance, and misalignment compensation. Opt for ball bearings when prioritizing low friction, high-speed operation, and compact design in moderate load applications.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025