พ.ย. . 20, 2024 22:01 Back to list

spherical roller bearing failure analysis

Spherical Roller Bearing Failure Analysis

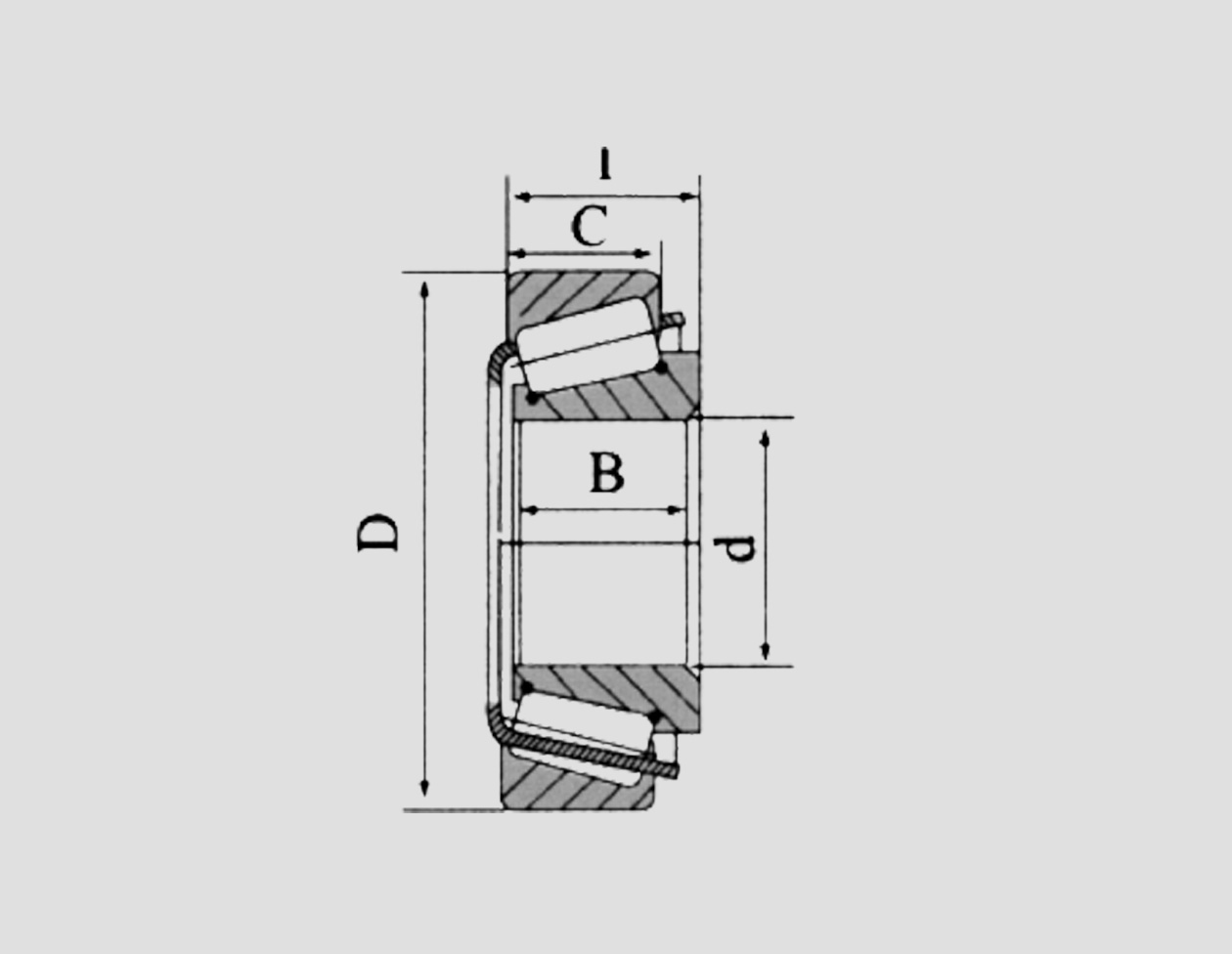

Spherical roller bearings are essential components in a wide range of mechanical systems, particularly in rotating machinery. Their unique design allows for both radial and axial load support, making them ideal for applications such as wind turbines, construction equipment, and industrial machines. However, like all mechanical parts, they are susceptible to failure, which can lead to significant downtime and costly repairs. Therefore, understanding the potential failure modes and conducting a thorough failure analysis is critical for maintaining the reliability of machinery.

Types of Failures

Spherical roller bearings can experience a variety of failure modes, the most common being fatigue, wear, lubrication issues, and misalignment. Fatigue failure often leads to the formation of surface cracks and ultimately spalling of the raceway. This is typically a progressive failure that occurs due to repeated stress cycles on the bearing surfaces, often exacerbated by inadequate lubrication or improper installation.

Wear is another common failure mode and can be caused by abrasive contaminants, poor alignment, or insufficient lubrication. Over time, wear can lead to surface degradation, increasing the gap between the rolling elements and the raceway, contributing further to operational inefficiencies and potential breakdown.

Lubrication issues can arise from either over-lubrication or under-lubrication. Under-lubrication can lead to increased friction and heat generation, resulting in overheating and eventual failure. Conversely, over-lubrication can cause excessive pressure within the bearing housing, leading to potential seals failure and leakage.

Misalignment is often due to improper installation or operational conditions and can lead to uneven load distribution on the rolling elements

. This uneven load can cause premature wear and, for spherical roller bearings specifically, may lead to a significant reduction in their lifespan.spherical roller bearing failure analysis

Failure Analysis Process

To effectively analyze bearing failures, a systematic approach is adopted, which typically involves visual inspections, material analysis, and operational evaluations.

1. Visual Inspection The first step in failure analysis is often a visual inspection of the bearing and its surrounding components. Signs of discoloration, pitting, or spalling on the raceway can indicate fatigue failures. In contrast, debris or wear particles can point to lubrication issues or contamination.

2. Material Analysis Advanced techniques such as scanning electron microscopy (SEM) can provide insights into the microstructural changes in the materials resulting from fatigue. This can help determine the root cause of the failure and whether it was due to inherent material defects or operational stresses.

3. Operational Evaluation Assessing the operating conditions under which the bearing was used is vital. This includes examining load conditions, speeds, lubrication practices, and alignment setups. Through this evaluation, it becomes easier to identify whether the failure was a result of design inadequacies or operational mismanagement.

Conclusion

The analysis of spherical roller bearing failures is crucial not only for understanding the immediate cause of downtime but also for implementing preventive measures. By recognizing the common failure modes—fatigue, wear, lubrication issues, and misalignment—and adopting a systematic approach to failure analysis, operators can improve the reliability and lifespan of their machinery. Regular maintenance, proper installation, and adherence to operational specifications play a pivotal role in mitigating the risk of bearing failure, ensuring smoother operations, and reducing costs associated with unplanned downtimes. Through diligent monitoring and analysis, organizations can foster a more robust mechanical environment that enhances performance and efficiency.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025