мар . 06, 2025 12:24 Back to list

cylindrical roller bearing sizes

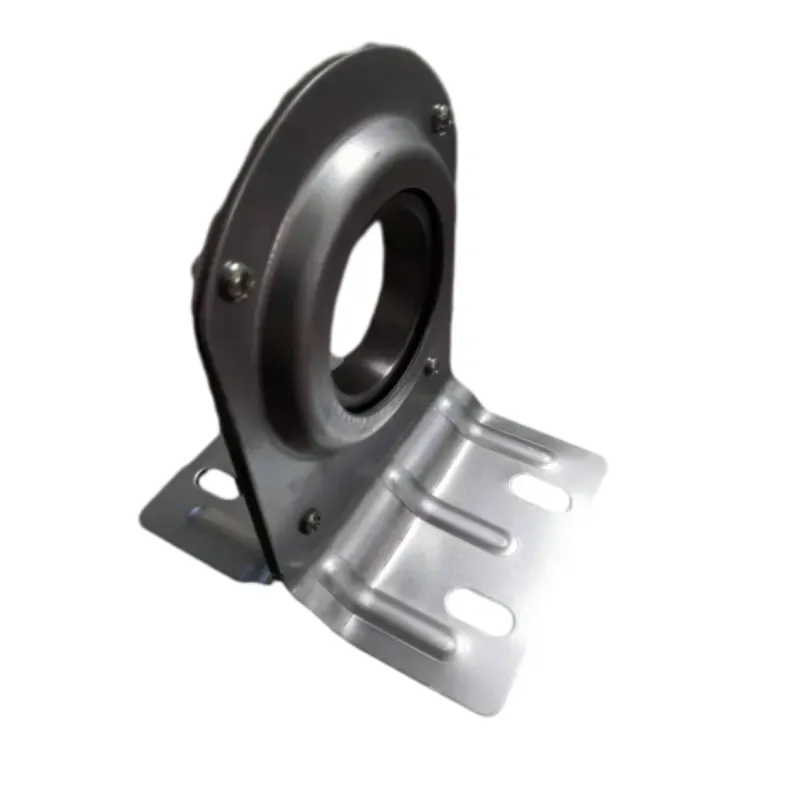

Navigating the intricate world of mechanical components, understanding the nuances of cylindrical roller bearing sizes is paramount for industries that rely on precise machine operations. These bearings play a crucial role in reducing friction and supporting radial and axial loads in various industrial applications, including manufacturing, heavy machinery, and automotive sectors.

In terms of authoritativeness, the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) have established standardized sizes and classifications for cylindrical roller bearings. Adhering to these standards guarantees that the bearings fit seamlessly into internationally designed machinery, offering users confidence in their installations. It's also crucial for industry professionals to refer to these standards when specifying bearing sizes for both new equipment and replacement scenarios. Trustworthiness in selecting cylindrical roller bearing sizes stems from working with reputable manufacturers who provide comprehensive data sheets and technical support. Transparency in material composition, testing results, and compliance with international standards ensures that the chosen bearings will perform reliably under specified conditions. When sourcing bearings, it is vital to consider the manufacturer's reputation and history within the industry. Companies with a long-standing commitment to innovation and quality control are often seen as trustworthy partners. To sum it up, selecting the appropriate cylindrical roller bearing sizes is a decisive factor in the efficiency and durability of machinery. Backed by experience and expertise, choosing the correct bearing size requires assessing the specific demands of the application, consulting authoritative standards, and partnering with manufacturers known for their commitment to quality and transparency. By prioritizing these elements, industries can significantly mitigate risks and improve operational resilience, ensuring machinery remains in optimal working condition across diverse applications.

In terms of authoritativeness, the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) have established standardized sizes and classifications for cylindrical roller bearings. Adhering to these standards guarantees that the bearings fit seamlessly into internationally designed machinery, offering users confidence in their installations. It's also crucial for industry professionals to refer to these standards when specifying bearing sizes for both new equipment and replacement scenarios. Trustworthiness in selecting cylindrical roller bearing sizes stems from working with reputable manufacturers who provide comprehensive data sheets and technical support. Transparency in material composition, testing results, and compliance with international standards ensures that the chosen bearings will perform reliably under specified conditions. When sourcing bearings, it is vital to consider the manufacturer's reputation and history within the industry. Companies with a long-standing commitment to innovation and quality control are often seen as trustworthy partners. To sum it up, selecting the appropriate cylindrical roller bearing sizes is a decisive factor in the efficiency and durability of machinery. Backed by experience and expertise, choosing the correct bearing size requires assessing the specific demands of the application, consulting authoritative standards, and partnering with manufacturers known for their commitment to quality and transparency. By prioritizing these elements, industries can significantly mitigate risks and improve operational resilience, ensuring machinery remains in optimal working condition across diverse applications.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025