Aug . 06, 2025 17:32 Toe fo'i i le lisi

Agricultural Equipment Bearings: A Power Hub for Intensive Cultivation under Radial Space Constraints

With the continuous development of modern agricultural machinery towards refinement and compactness, Pisiga Meafaigaluega Faatoaga, which are suitable for limited radial space, have become key components to ensure efficient operation of agricultural machinery due to their exquisite design and powerful performance, providing reliable support for various aspects of agricultural production in narrow spaces.

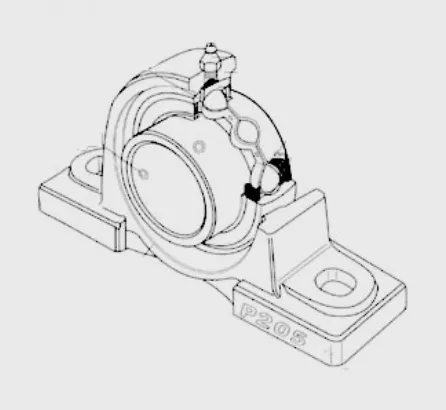

This type of Agricultural Equipment Bearing has a unique and ingenious structural design

To meet the special requirements of limited radial space, the ball bearing machine adopts a compact design, reducing the outer diameter size while optimizing the internal structure. For example, thin-walled bearings effectively save space without sacrificing load-bearing capacity by reducing the thickness of the ring wall; Needle roller bearings replace ball bearings with slender needles, significantly reducing radial dimensions and meeting installation requirements in narrow spaces. At the same time, some bearings also integrate functional components such as sealing and lubrication, reducing additional space occupation and improving the compactness and integration of the overall structure.

In terms of performance, Agricultural Equipment Bearings demonstrate excellent adaptability and reliability

Despite the limited radial size, it still has excellent load-bearing capacity through the use of high-strength materials and advanced manufacturing processes, and can withstand the large radial and axial loads generated by agricultural machinery during farming, harvesting, and other operations. High precision manufacturing standards ensure the low friction operation characteristics of bearings, reduce energy consumption, and improve equipment transmission efficiency. Moreover, good sealing and protective design enable it to operate stably in harsh agricultural environments filled with soil, dust, moisture, etc., effectively extending its service life and reducing maintenance frequency.

Among the many equipment used in agricultural production, Agricultural Equipment Bearings play an indispensable role

In small seeders, compact ball mill white metal bearings can be installed on the drive shaft of the seeder with limited space, ensuring precise and orderly seeding of seeds; The key components of the combine harvester, such as the cutting table and threshing drum, use bearings with limited radial dimensions to achieve efficient operation in a compact structure and complete complex tasks such as crop harvesting and threshing; In addition, in agricultural equipment such as orchard management machinery and greenhouse irrigation equipment that require high space, such bearings also provide strong support for the stable operation of the equipment with their unique advantages.

With the acceleration of agricultural modernization, Agricultural Equipment Bearings suitable for limited radial space are also continuously innovating and breaking through

The application of new materials such as high-strength ceramics and nanocomposites further enhances the performance and service life of bearing heating machines; The integration of intelligent technology enables the built-in sensors of bearings to monitor operating status, temperature, load and other parameters in real time, achieving fault warning and intelligent maintenance; Meanwhile, with the help of computer-aided design and simulation technology, the bearing structure has been further optimized, continuously improving its overall performance while meeting space constraints.

In summary, the bearing making machine suitable for limited radial space, with its exquisite structural design, excellent performance, and continuous technological innovation, has become the core guarantee for modern agricultural machinery to achieve efficient operation in compact spaces. They not only solve the problem of limited space for agricultural equipment, but also provide strong support for the refinement and intelligent development of agricultural production. In the future, with the continuous advancement of agricultural technology, Agricultural Equipment Bearings will play a key role in more agricultural machinery fields, helping agricultural production move towards higher levels.

Agricultural Equipment Bearings FAQs

How to choose suitable Agricultural Equipment Bearings when radial space is limited?

Prioritize the use of thin-walled bearings (such as thin-walled deep groove ball bearings or angular contact bearings), which have a low cross-sectional height and balanced load-bearing capacity, making them suitable for compact designs. Needle roller bearings can also be considered, with extremely small radial cross-sections that can withstand high radial loads.

How do Agricultural Equipment Bearings deal with dust and mud in agricultural environments?

Choose bearings with rubber sealing rings (such as 2RS or ZZ type), or adopt a design with outer rings and dust covers. If the corrosion is severe, stainless steel material or surface coating bearings can be selected.

How to ensure the lifespan of Agricultural Equipment Bearings under high loads?

When space is limited, fully loaded roller bearings (such as fully loaded cylindrical roller bearings) can be used. The design without a cage increases the number of rolling elements and improves the load-bearing capacity, but attention should be paid to speed limitations.

How to avoid positioning deviation caused by small space when installing Agricultural Equipment Bearings?

Using split type bearings or flange mounted bearings for easy adjustment of centering in narrow spaces; Ensure the machining accuracy of the shaft and bearing seat (recommended IT6 level tolerance).

What are the special requirements for lubrication and maintenance of Agricultural Equipment Bearings?

Prioritize using lifelong grease sealed bearings (such as those with lithium based grease) to reduce maintenance frequency; If the environment is harsh, lubricant can be replenished through an external oil nozzle, but attention should be paid to sealing.

Tala fou

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

Tala FouNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

Tala FouNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

Tala FouNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

Tala FouNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

Tala FouNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

Tala FouNov.22,2025