Dez . 30, 2024 23:20 Back to list

spherical roller thrust bearing sizes

Understanding Spherical Roller Thrust Bearing Sizes

Spherical roller thrust bearings are a specialized type of bearing designed to accommodate axial loads in high-performance applications. Unlike traditional roller bearings that primarily support radial loads, these bearings can take on significant axial loads along with limited radial loads, making them indispensable in various engineering applications, particularly in heavy machinery and manufacturing equipment. Understanding the sizes and specifications of spherical roller thrust bearings is crucial for ensuring optimal performance and longevity in machinery.

What Are Spherical Roller Thrust Bearings?

Spherical roller thrust bearings consist of spherical-shaped rolling elements that are housed within a cage. The unique design allows the rollers to align themselves with the shaft and the raceways, accommodating angular misalignments effectively. This feature makes them ideal for applications where conditions can cause misalignment, such as in marine, mining, and heavy-duty industrial machines. The bearings are proficient in handling high speeds and heavy loads, ensuring machinery operates efficiently.

Size Specification of Spherical Roller Thrust Bearings

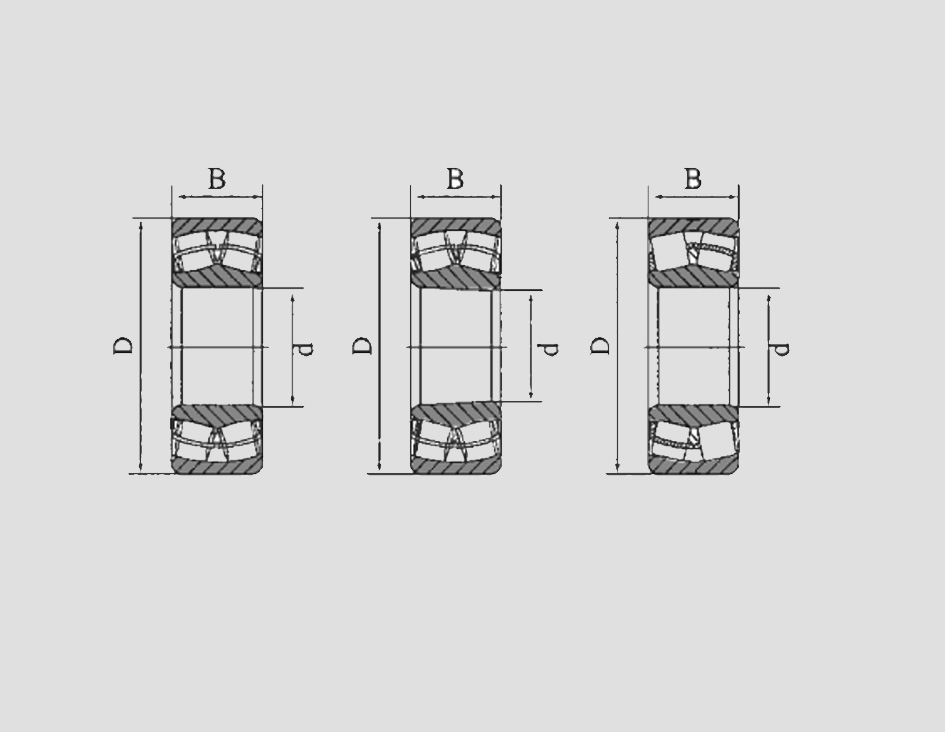

The size of a spherical roller thrust bearing is primarily characterized by its bore diameter, outer diameter, and width. Each bearing size is defined by specific numerical codes that enable easy identification. The International Organization for Standardization (ISO) provides standardized dimensions to ensure compatibility and interchangeability worldwide.

1. Bore Diameter This is the internal diameter of the bearing and is crucial for ensuring a perfect fit with the shaft. The bore sizes can vary significantly, ranging from a few millimeters to several hundred millimeters. Manufacturers typically offer a variety of size options to suit different applications.

2. Outer Diameter The outer diameter is the diameter of the bearing’s outer ring. This measurement determines how the bearing fits within its housing. Correct outer diameter selection is essential for proper alignment and load distribution.

3. Width The width of the bearing, or thickness, is also a critical dimension. It influences the load-carrying capacity and must be selected based on the application’s specific load requirements.

spherical roller thrust bearing sizes

Importance of Size Selection

Selecting the right size for a spherical roller thrust bearing is vital for several reasons

- Load Capacity The size of the bearing directly affects its load-carrying capacity. Larger bearings can typically handle more substantial loads, while smaller bearings are suited for lighter applications. Engineers must calculate expected loads and choose a bearing size that meets or exceeds these requirements.

- Fit and Alignment A correctly sized bearing will fit snugly on the shaft and within the housing, promoting better alignment and reducing wear. Poor fit caused by incorrect sizing can lead to premature failure and costly downtime.

- Performance Efficiency Properly sized bearings function more efficiently, reducing friction and heat generation during operation. This enhanced performance can extend the life of both the bearing and the machinery it serves.

Conclusion

Spherical roller thrust bearings play a vital role in many industrial applications, and understanding their sizes is essential for engineers and technicians. Ensuring the right selection based on bore diameter, outer diameter, and width will not only improve machinery performance but also enhance reliability and longevity.

When selecting spherical roller thrust bearings, it is essential to consult manufacturer specifications and utilize standardized codes to identify the appropriate size for your application. Incorporating these bearings appropriately into machinery design can lead to improved operational efficiency and reduced maintenance costs over time. Ultimately, attention to detail in the selection of bearing sizes will translate to better machinery performance in demanding environments.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025