Dec . 19, 2024 21:30 Back to list

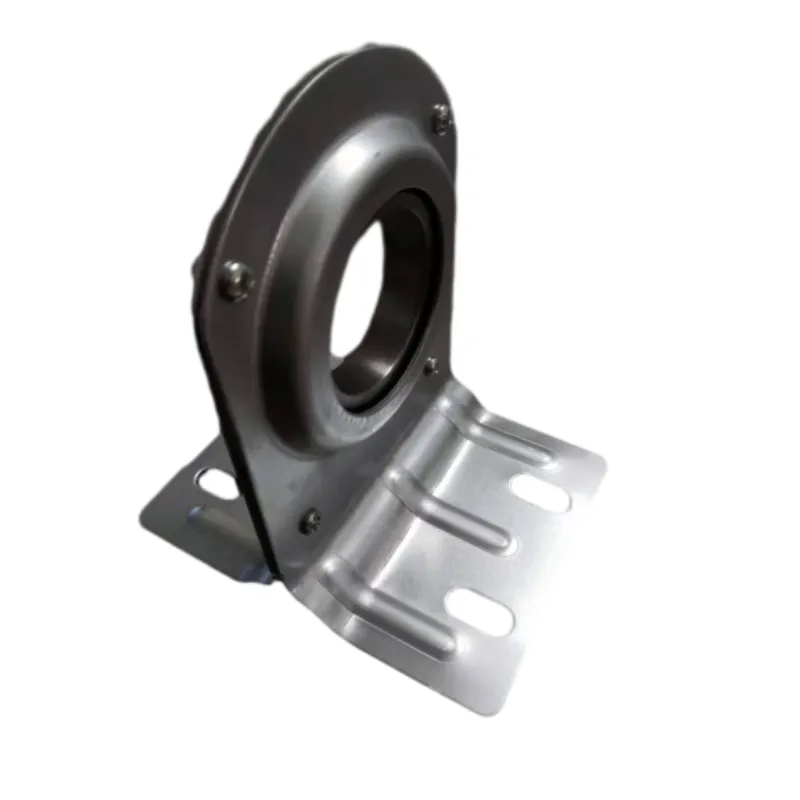

diameter bearing 6203

Understanding the Diameter Bearing 6203 A Comprehensive Guide

When it comes to machinery, smooth operation and longevity are key factors that manufacturers and engineers prioritize. One crucial component that plays a significant role in achieving these goals is the bearing. Among the many types of bearings available, the diameter bearing 6203 stands out due to its reliability, versatility, and widespread application. In this article, we will delve into the specifics of the 6203 bearing, including its design, applications, and maintenance.

What is a Diameter Bearing 6203?

The 6203 bearing is a type of deep groove ball bearing, which is characterized by its simple structure and high load-bearing capacity. Its designation 6203 specifies a bearing with an inner diameter of 17 mm, an outer diameter of 40 mm, and a width of 12 mm. These dimensions allow it to fit in various mechanisms, making it an ideal choice for numerous applications. The 6203 bearing typically consists of an outer ring, an inner ring, a set of balls, and a cage that holds the balls in place.

Design Features

One of the notable features of the 6203 bearing is its deep groove design, which facilitates effective load distribution. This design minimizes stress at the contact points between the balls and the races (the inner and outer rings), allowing it to handle both radial and axial loads. Furthermore, the 6203 bearing can accommodate misalignment and slight angular misalignment between the shafts and housings, which enhances its performance and lifespan.

The 6203 bearing is available in various materials, including stainless steel and chrome steel. Stainless steel variants offer enhanced resistance to corrosion, making them suitable for applications in moist or chemically aggressive environments. The raceways and balls are typically hardened, ensuring durability and efficiency in operation.

Applications of the 6203 Bearing

Due to its dimensions and design, the 6203 bearing finds a myriad of applications across different industries. Commonly used in electric motors, household appliances, industrial machinery, and automotive applications, its versatility is one of its strongest qualities.

diameter bearing 6203

In the automotive industry, the 6203 bearing is often utilized in components such as alternators, starters, and wheels, where smooth rotation is essential for optimal performance. In industrial settings, it is frequently used in conveyor systems and pumps. Household appliances, including washing machines and fans, also rely on the reliable operation of the 6203 bearing.

Maintenance and Longevity

For any bearing, maintenance is crucial to ensure longevity and performance. The 6203 bearing, while designed for durability, benefits from regular maintenance checks. Here are some essential maintenance tips

1. Lubrication Bearings require proper lubrication to reduce friction and wear. Depending on the application, grease or oil may be used. It's important to follow the manufacturer's specifications regarding lubrication intervals.

2. Inspection Regularly check for signs of wear, such as noise, vibration, or an increase in operating temperature. Early detection of these symptoms can prevent serious damage.

3. Cleaning In dusty or dirty environments, keeping the bearing clean is essential. Contaminants can lead to premature failure, so using seals or shields can enhance protection.

4. Alignment Ensuring that the bearing is properly aligned during installation can prevent unnecessary stress and ultimately prolong its life.

Conclusion

The diameter bearing 6203 is a fundamental component in the design and operation of numerous machines and devices. Its robust construction, ability to handle various loads, and adaptability to different environments make it a reliable choice across diverse industries. Understanding its features, applications, and maintenance requirements is crucial for engineers and technicians who strive for efficiency and longevity in their machinery. By prioritizing proper care and maintenance, the lifespan of the 6203 bearing can be maximized, ensuring optimal performance and smoother operations for years to come.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025