Mar . 06, 2025 13:56 Back to list

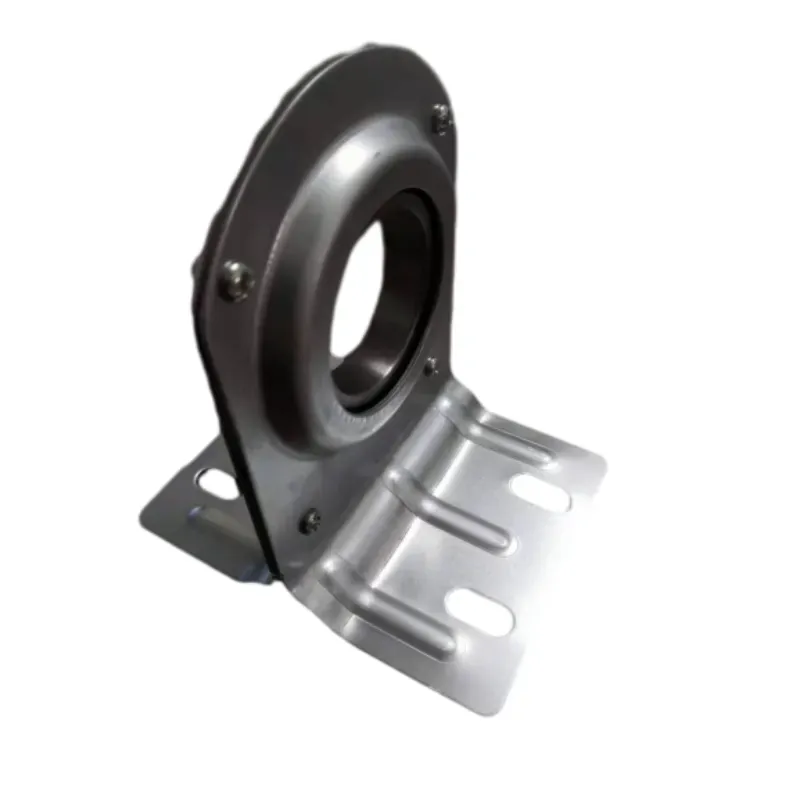

cylindrical roller bearings

Cylindrical roller bearings play a pivotal role in the smooth and efficient operation of machinery across various industries. Engineered to handle heavy radial loads and operate under high-speed conditions, these bearings are crucial components that ensure the reliability and performance of equipment. Let's delve into the specifics of their applications, advantages, and why they remain a preferred choice for many professionals in the field of mechanical engineering.

In terms of maintenance, cylindrical roller bearings contribute significantly to the ease of equipment upkeep. Their simple construction facilitates straightforward assembly and disassembly processes, which is invaluable in minimizing downtime during maintenance operations. This is a critical factor in industries where operational continuity is essential, such as in chemical processing plants that operate around the clock. The reliability and ease of maintenance of these bearings make them a preferred choice for engineers tasked with ensuring the consistent performance of essential equipment. The expertise behind cylindrical roller bearings is rooted in advanced engineering and materials science. Manufacturers leverage cutting-edge technology and materials to enhance the performance characteristics of these bearings. The use of high-grade steel and precision manufacturing processes ensure that the bearings can withstand the stresses they encounter while maintaining optimal functionality. This commitment to quality and innovation positions manufacturers as trusted partners to industries that demand the utmost in performance and reliability. Authoritativeness in the field of cylindrical roller bearings is often established through rigorous testing and adherence to international standards. Leading manufacturers invest heavily in research and development, collaborating with academic institutions and industry partners to continuously improve bearing technology. Compliance with standards such as ISO and ANSI not only affirms the quality of the bearings but also instills confidence in end-users regarding their efficacy and safety. Building trustworthiness in cylindrical roller bearings involves transparent communication about their capabilities and limitations. Providing detailed product specifications, performance data, and case studies demonstrating real-world applications reinforces the credibility of the product. Education initiatives, such as training sessions and workshops for engineers and maintenance teams, further solidify the reputation of manufacturers as authorities on bearing technology. In summary, cylindrical roller bearings are indispensable components that cater to a wide array of industrial applications. Their ability to manage heavy radial loads, versatility in design, efficiency, and ease of maintenance make them an expert choice for ensuring the smooth operation of machinery across industries. By continuously advancing bearing technology and maintaining stringent quality standards, manufacturers uphold their authoritative status and foster trust among their clients, reaffirming the critical role these components play in modern engineering.

In terms of maintenance, cylindrical roller bearings contribute significantly to the ease of equipment upkeep. Their simple construction facilitates straightforward assembly and disassembly processes, which is invaluable in minimizing downtime during maintenance operations. This is a critical factor in industries where operational continuity is essential, such as in chemical processing plants that operate around the clock. The reliability and ease of maintenance of these bearings make them a preferred choice for engineers tasked with ensuring the consistent performance of essential equipment. The expertise behind cylindrical roller bearings is rooted in advanced engineering and materials science. Manufacturers leverage cutting-edge technology and materials to enhance the performance characteristics of these bearings. The use of high-grade steel and precision manufacturing processes ensure that the bearings can withstand the stresses they encounter while maintaining optimal functionality. This commitment to quality and innovation positions manufacturers as trusted partners to industries that demand the utmost in performance and reliability. Authoritativeness in the field of cylindrical roller bearings is often established through rigorous testing and adherence to international standards. Leading manufacturers invest heavily in research and development, collaborating with academic institutions and industry partners to continuously improve bearing technology. Compliance with standards such as ISO and ANSI not only affirms the quality of the bearings but also instills confidence in end-users regarding their efficacy and safety. Building trustworthiness in cylindrical roller bearings involves transparent communication about their capabilities and limitations. Providing detailed product specifications, performance data, and case studies demonstrating real-world applications reinforces the credibility of the product. Education initiatives, such as training sessions and workshops for engineers and maintenance teams, further solidify the reputation of manufacturers as authorities on bearing technology. In summary, cylindrical roller bearings are indispensable components that cater to a wide array of industrial applications. Their ability to manage heavy radial loads, versatility in design, efficiency, and ease of maintenance make them an expert choice for ensuring the smooth operation of machinery across industries. By continuously advancing bearing technology and maintaining stringent quality standards, manufacturers uphold their authoritative status and foster trust among their clients, reaffirming the critical role these components play in modern engineering.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025