jan . 24, 2025 02:33 Back to list

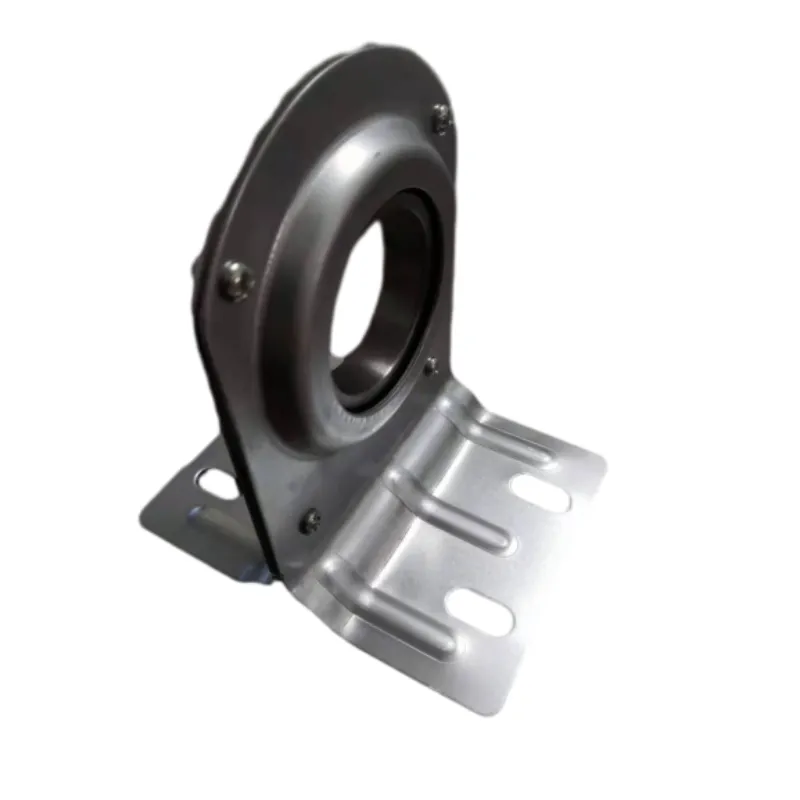

deep groove ball bearing

When it comes to precision engineering components, bearings stand as indispensable elements central to the smooth operation of countless machinery and equipment. The specific configuration of a 25 * 62 * 15 bearing is one such example, catering to specialized applications demanding exact dimensions and performance characteristics.

Choosing the Right Supplier For businesses seeking reliable bearings for their machinery, partnering with a reputable supplier is crucial. A supplier with a proven track record in producing high-quality bearings enhances not only the performance of the machinery but also instills confidence in its continued reliability. Such suppliers offer verified technical documents and bearings produced under certified quality management systems, further ensuring the product's authority and trustworthiness. User Experience and Maintenance Regular maintenance and correct installation play essential roles in maximizing the life and performance of the 25 * 62 * 15 bearing. Technicians emphasize the importance of proper lubrication and periodic checks for signs of wear and tear as part of the routine maintenance schedule. Adequate user training in understanding these maintenance requirements can significantly enhance operational efficiency, reduce downtime, and increase the overall trustworthiness of the machinery in commercial applications. In sectors like automotive repair or machine tool outfitting, user feedback continually shapes the development and improvement of these components. Listening to end-user experiences allows manufacturers to innovate and tailor bearings like the 25 * 62 * 15 to meet evolving needs and conditions, thereby advancing the field of mechanical components and providing new solutions. In Conclusion The 25 * 62 * 15 bearing offers an exemplary case of how specialized components rise to meet industrial challenges. Through its precise design, robust durability, and efficient performance, it stands as a testament to modern engineering prowess. As advancements continue in bearing technology, industries worldwide will benefit from the ever-increasing standards of quality and performance that bearings like these demonstrate. The combination of meticulous manufacturing practices, authoritative quality management, and ongoing innovation ensures that the 25 * 62 * 15 bearing continues to be a trusted choice in both current and future applications.

Choosing the Right Supplier For businesses seeking reliable bearings for their machinery, partnering with a reputable supplier is crucial. A supplier with a proven track record in producing high-quality bearings enhances not only the performance of the machinery but also instills confidence in its continued reliability. Such suppliers offer verified technical documents and bearings produced under certified quality management systems, further ensuring the product's authority and trustworthiness. User Experience and Maintenance Regular maintenance and correct installation play essential roles in maximizing the life and performance of the 25 * 62 * 15 bearing. Technicians emphasize the importance of proper lubrication and periodic checks for signs of wear and tear as part of the routine maintenance schedule. Adequate user training in understanding these maintenance requirements can significantly enhance operational efficiency, reduce downtime, and increase the overall trustworthiness of the machinery in commercial applications. In sectors like automotive repair or machine tool outfitting, user feedback continually shapes the development and improvement of these components. Listening to end-user experiences allows manufacturers to innovate and tailor bearings like the 25 * 62 * 15 to meet evolving needs and conditions, thereby advancing the field of mechanical components and providing new solutions. In Conclusion The 25 * 62 * 15 bearing offers an exemplary case of how specialized components rise to meet industrial challenges. Through its precise design, robust durability, and efficient performance, it stands as a testament to modern engineering prowess. As advancements continue in bearing technology, industries worldwide will benefit from the ever-increasing standards of quality and performance that bearings like these demonstrate. The combination of meticulous manufacturing practices, authoritative quality management, and ongoing innovation ensures that the 25 * 62 * 15 bearing continues to be a trusted choice in both current and future applications.

Next:

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025