sep . 24, 2024 18:53 Back to list

Understanding the Function and Types of Thrust Bearings in Mechanical Systems

Understanding Thrust Bearings An Essential Component in Machinery

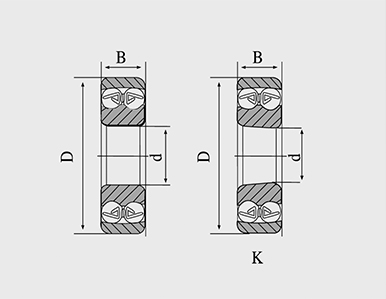

Thrust bearings play a crucial role in various mechanical systems, serving as a key component that supports axial loads and ensures smooth operation. Unlike traditional bearings that primarily handle radial loads, thrust bearings are specifically designed to manage forces that act along the shaft's axis. This capability makes them essential in applications where heavy loads are exerted in a linear direction.

Understanding Thrust Bearings An Essential Component in Machinery

On the other hand, roller thrust bearings utilize cylindrical rollers to provide a greater load-carrying capacity. This design allows them to manage higher speeds and loads, making them ideal for applications such as turbines, gearboxes, and various industrial machinery. The choice between these types depends largely on the requirements of the specific application, including load capacity, speed, and operating environment.

what is the thrust bearing

One of the critical characteristics of thrust bearings is their ability to minimize friction between moving parts. By using lubrication, thrust bearings reduce wear and tear, thereby extending the lifespan of machinery. Proper maintenance, such as regular lubrication, is essential to ensure that thrust bearings function optimally and prevent premature failure.

In industrial settings, thrust bearings are often used in conjunction with other types of bearings, creating a comprehensive bearing system that can effectively handle both radial and axial loads. This versatility is particularly important in high-demand environments, where equipment reliability is vital for operational efficiency.

In summary, thrust bearings are indispensable components in many mechanical systems, providing support against axial loads and enhancing the performance of machinery. Understanding their different types, functions, and maintenance needs is crucial for engineers and technicians aiming to ensure the longevity and efficiency of their equipment. As technology advances, the design and materials used in thrust bearings continue to evolve, paving the way for even greater performance and reliability in future applications.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025