Nov . 07, 2024 00:36 Back to list

what is a tapered bearing

What is a Tapered Bearing?

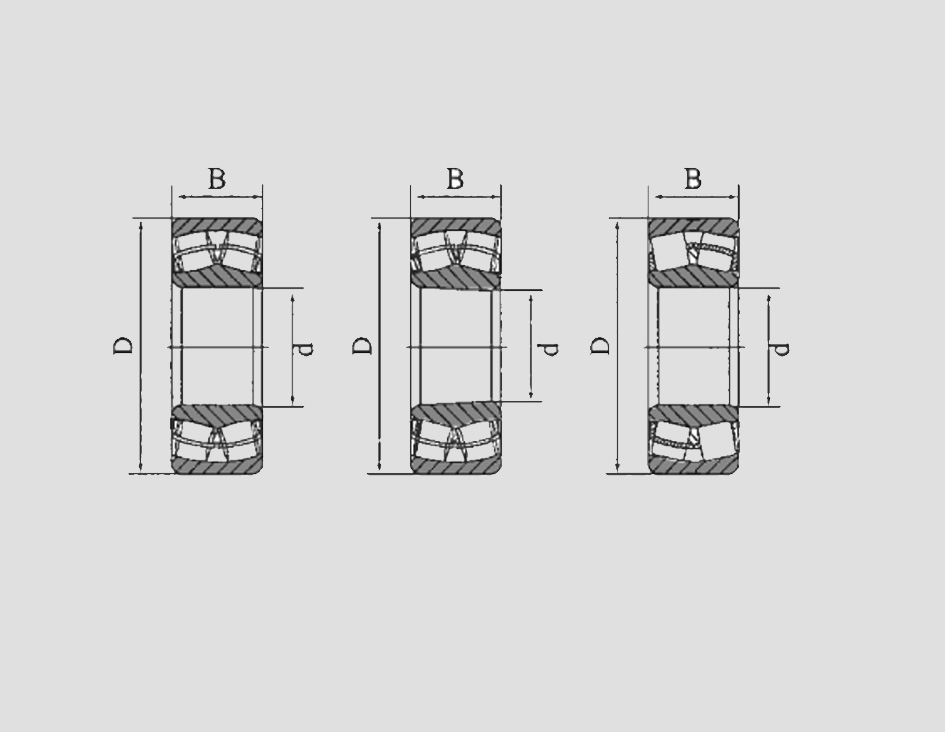

Tapered bearings, also known as tapered roller bearings, are a type of rolling-element bearing that can support both axial and radial loads. Their unique design allows for applications requiring high speed and load capacity, making them essential in various industries such as automotive, aerospace, and manufacturing.

The fundamental structure of a tapered bearing consists of two main components the cone and the cup. The cone is made up of an inner ring and roller elements, while the cup serves as the outer ring. The rollers have a tapered shape, allowing them to make line contact with the raceway surfaces at a slight angle. This design enables the bearing to handle higher loads compared to other types of bearings, as the angle of contact distributes the load over a larger surface area.

Key Features and Benefits

One of the salient features of tapered bearings is their ability to support axial loads in one direction while also accommodating radial loads. This dual functionality is particularly advantageous in applications such as wheel hubs, where both types of loads are present. The tapered design also allows for adjustment of internal clearance, which can improve performance and longevity.

Another benefit of tapered bearings is their ability to handle variations in load and speed. The alignment of the rollers with the raceways helps minimize friction, reducing wear and prolonging the life of the bearing. This characteristic is crucial in high-speed applications where traditional bearings may fail due to overheating and excessive friction.

what is a tapered bearing

Applications of Tapered Bearings

The versatility of tapered bearings makes them suitable for a variety of applications. In the automotive industry, they are commonly used in wheel bearings, transmission systems, and differential assemblies. Their robust design enables vehicles to operate smoothly even under heavy loads and extreme driving conditions.

In the industrial sector, tapered bearings can be found in heavy machinery, conveyor systems, and construction equipment. These machines often operate under fluctuating loads and harsh environments, making the reliability of tapered bearings vital for operational efficiency and safety.

In aerospace applications, tapered bearings are utilized in landing gears and engines. Their capability to handle significant forces and provide stability is paramount in the demanding conditions faced during flight.

Conclusion

Tapered bearings are an essential component of modern machinery and vehicles, offering a unique combination of load capacity, durability, and versatility. Their ability to manage both axial and radial loads optimally makes them indispensable in various industries, from automotive to aerospace. As technology continues to advance, the design and materials used in tapered bearings will likely evolve, further enhancing their performance and applications. Understanding the fundamental principles behind tapered bearings is crucial for engineers and technicians involved in design and maintenance, ensuring reliability and efficiency in their respective fields.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025