Aug . 22, 2024 05:43 Back to list

Understanding Tapered Roller Bearing Number Chart for Effective Selection and Use

Understanding Taper Roller Bearing Number Chart

Taper roller bearings are widely used in various applications due to their ability to support both radial and axial loads. These bearings are characterized by their conical shape, which allows for better alignment with the shaft and casings. A crucial aspect to understand when working with taper roller bearings is their number chart, which provides essential information for identifying and selecting the appropriate bearings for different applications.

What are Taper Roller Bearings?

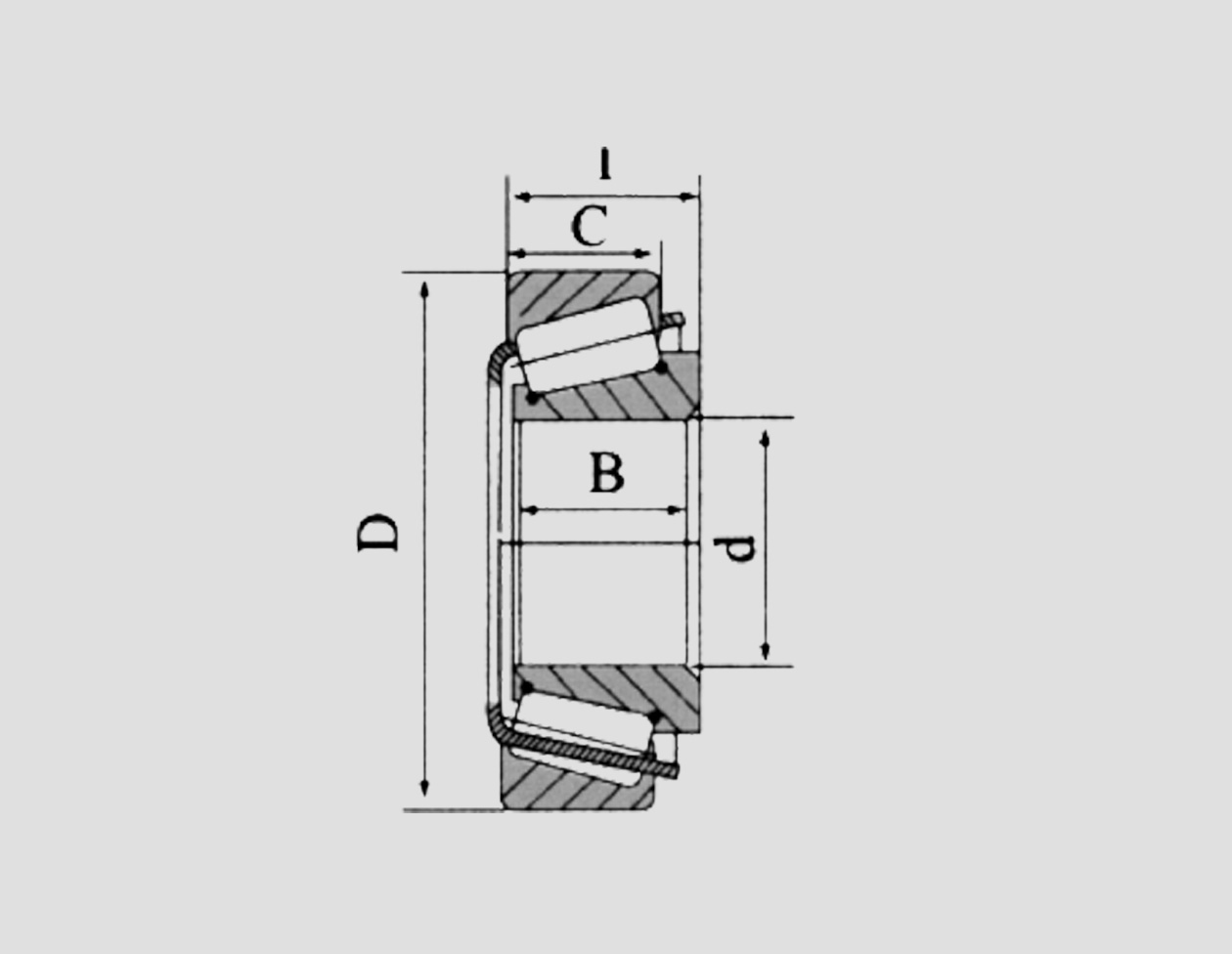

Taper roller bearings consist of an inner ring, an outer ring, a cage, and tapered rolling elements. The design allows the roller elements to make contact with the raceways at a specific angle, which helps to distribute the load evenly across the bearing. This unique design enables them to carry heavier loads compared to standard roller bearings, making them ideal for use in automotive, aerospace, and industrial machinery applications.

The Importance of Bearing Number Charts

Bearing number charts serve as a universal language for identifying and categorizing bearings. These charts provide a systematic way to decode the various components of a bearing's part number, which typically includes information about the bearing type, size, design, and any special features. For taper roller bearings, the number chart is particularly important because it helps engineers and maintenance personnel select the correct bearing that meets the specific load and performance requirements of a given application.

Decoding the Taper Roller Bearing Number

Typically, the number for taper roller bearings consists of a combination of letters and numbers. The first part of the number often indicates the type of bearing. For example, T may stand for a taper roller bearing. The subsequent digits usually denote the size and dimension of the bearing, such as the outer diameter, inner diameter, and width.

taper roller bearing number chart

For example, a bearing numbered 30206 can be deciphered as follows - 30 - This specifies the series of the bearing. - 206 - This indicates the size range and dimensions, which can be looked up in the corresponding size chart to find exact measurements such as the cone's outer diameter and the cup's inner diameter.

Additionally, suffixes may be added to indicate specific features like different tolerances or finishes. Understanding these designations is crucial for ensuring that the bearing will function correctly in its intended application.

Application of Taper Roller Bearing Number Chart

When selecting taper roller bearings for applications such as automobile wheel hubs or machinery spindles, engineers refer to the bearing number chart to determine the most suitable options. Matching the part number to the specifications required for each application ensures optimal performance, longevity, and safety.

Moreover, when replacing bearings, using the correct number avoids compatibility issues. Many systems may require interchangeable parts, and the taper roller bearing number chart aids in finding a replacement that matches the original specifications precisely.

Conclusion

In conclusion, the taper roller bearing number chart is an invaluable tool for engineers, maintenance professionals, and anyone involved in bearing selection and replacement. Understanding the numbering system and being able to decode the information is essential for ensuring that the correct taper roller bearing is chosen for a specific application. This not only improves the efficiency and reliability of the machinery or vehicle but also extends the lifespan of the components involved. As industries continue to evolve, having a comprehensive grasp of bearing specifications and their number charts remains a fundamental skill for professionals in the field.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025