Aug . 05, 2024 21:50 Back to list

Understanding Miniature Deep Groove Ball Bearings and Their Applications in Precision Engineering and Robotics

Understanding Miniature Deep Groove Ball Bearings

Miniature deep groove ball bearings are essential components in various mechanical systems. These small yet robust devices play a critical role in enabling smooth rotational movement while minimizing friction and wear. Used widely across industries, from electronics to robotics, their design and functionality make them a go-to choice for countless applications.

Design Features

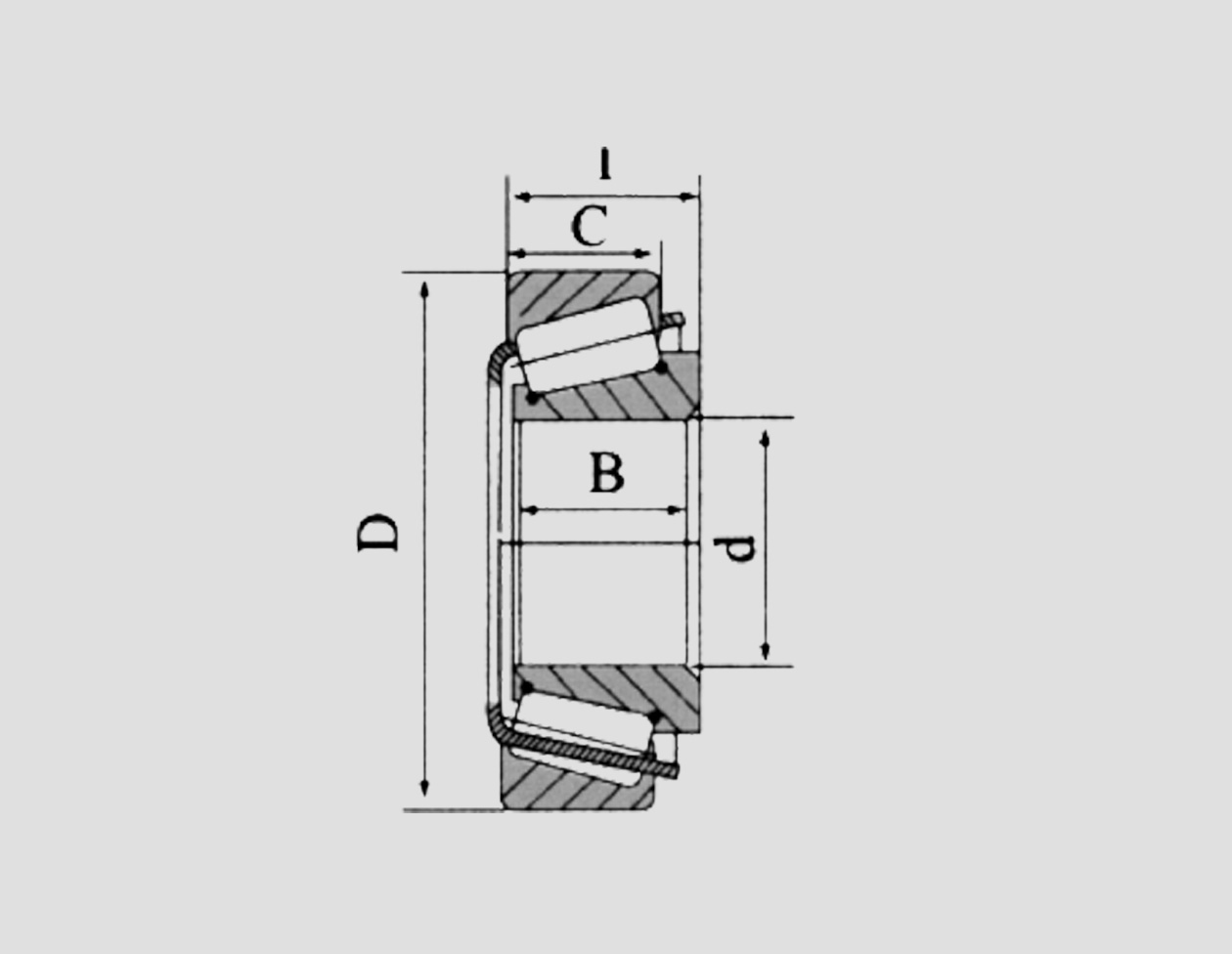

Miniature deep groove ball bearings are typically characterized by a few key features. Firstly, they have a simple structure, comprising an inner race, an outer race, balls, and a cage that holds the balls in place. They can be made from various materials, including stainless steel, chrome steel, or ceramic, depending on the specific application and environmental conditions.

The term deep groove refers to the shape of the raceways, which are designed to accommodate radial and axial loads in both directions. This configuration allows for higher load carrying capacity, stability, and efficiency. Additionally, the deep grooves ensure that the balls remain in contact with the raceways over a larger contact area, which reduces stress and enhances durability.

Advantages

One of the most significant advantages of miniature deep groove ball bearings is their ability to operate at high speeds while maintaining low noise levels. This characteristic is crucial for applications in sensitive environments, such as in medical devices or precision instruments. Moreover, their low friction properties translate to energy savings, making them more efficient in energy-intensive applications.

Miniature ball bearings also afford a high degree of customization. They come in various sizes, materials, and configurations, allowing engineers to select the best bearing type for their specific needs. For instance, sealed or shielded bearings are available for environments where contamination must be avoided, providing protection against dust and moisture.

miniature deep groove ball bearings

Applications

The versatility of miniature deep groove ball bearings lends them to a wide range of applications. In the electronic industry, they’re commonly used in hard drives, motors, and cooling fans, where size constraints are critical. In the model and hobbyist community, these bearings are employed in radio-controlled cars, drones, and other miniature devices where both weight and efficiency are paramount.

Moreover, in the medical field, miniature bearings are used in surgical equipment, diagnostic machines, and hospital bed mechanisms. Here, precision and reliability are crucial, and deep groove ball bearings provide the necessary performance standards.

Maintenance and Lifespan

To maximize the lifespan of miniature deep groove ball bearings, regular maintenance is recommended. This can include periodic lubrication, inspection, and cleaning to ensure that any debris or contaminants do not impede functionality. Depending on the application, the choice of lubricant can significantly impact the bearing's performance and durability.

The expected lifespan of these bearings can vary based on factors such as load, speed, and operating conditions. However, with proper care, they can last for many years, providing consistent performance in demanding applications.

Conclusion

In summary, miniature deep groove ball bearings are indispensable in modern machinery and equipment. Their unique design allows for high efficiency and low friction performance, making them suitable for various applications across multiple industries. Understanding their functionality, advantages, and maintenance needs can significantly enhance their effectiveness in achieving optimal performance in any mechanical setup. Whether in critical medical devices or high-speed electronics, these small components make a substantial impact on the overall efficiency and reliability of systems worldwide.

Latest news

-

common-failures-in-thrust-ball-bearings-and-solutions

NewsAug.22,2025

-

how-tapered-roller-bearings-can-take-shock-loads

NewsAug.22,2025

-

angular-bearings-in-high-precision-spindles

NewsAug.22,2025

-

the-impact-of-misalignment-on-cylindrical-roller-bearing-performance

NewsAug.22,2025

-

the-role-of-cage-design-in-deep-groove-ball-bearing-durability

NewsAug.22,2025

-

the-impact-of-material-quality-on-machinery-bearings-lifespan

NewsAug.22,2025