Dec . 27, 2024 05:41 Back to list

types of spherical roller bearings

Types of Spherical Roller Bearings

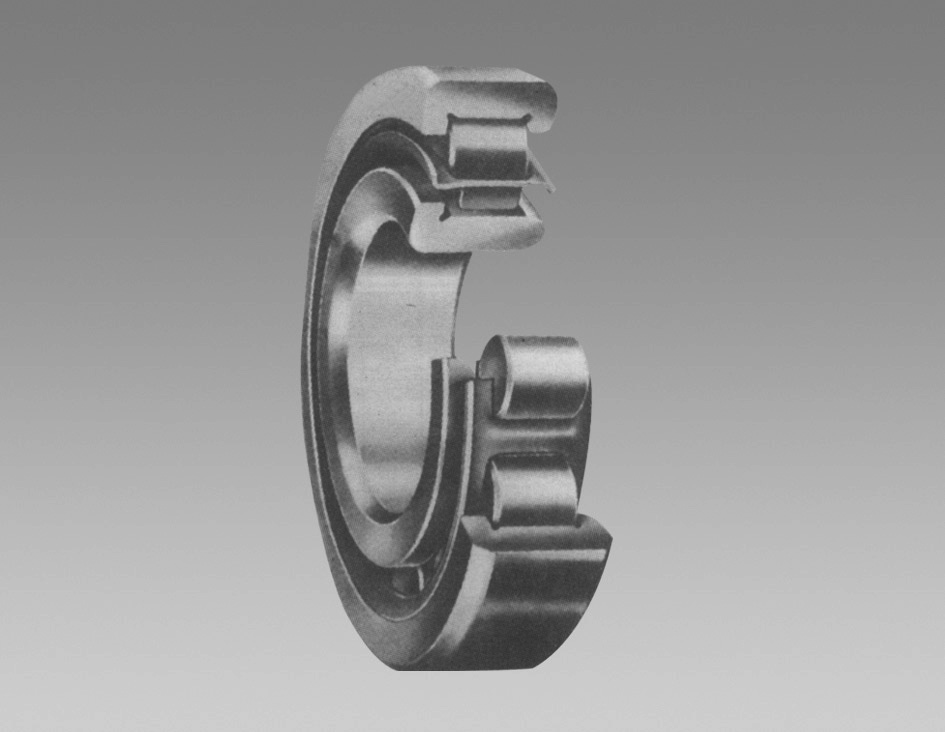

Spherical roller bearings are a crucial component in various mechanical systems, known for their ability to accommodate misalignment and support heavy radial and axial loads. Their unique design includes spherical outer surfaces that allow for angular misalignment between the shaft and the housing. This article explores the various types of spherical roller bearings, highlighting their features, applications, and advantages.

1. Design Features of Spherical Roller Bearings

Spherical roller bearings typically consist of an inner and outer ring with rolling elements (spherical rollers) situated between them. The outer ring has a spherical raceway, allowing the rollers to align themselves regardless of angular misalignment. Furthermore, these bearings can carry both radial and axial loads, making them versatile for many applications.

The internal design of spherical roller bearings includes multiple rows of rollers, typically two, which enhances their load-carrying capacity. The rollers are usually held in place by a cage or separator, which can be made from steel, brass, or polyamide, depending on the specific application and operating conditions.

2. Types of Spherical Roller Bearings

There are several types of spherical roller bearings, each designed for specific applications and operational conditions

A. Standard Spherical Roller Bearings

The most common type, standard spherical roller bearings, typically feature two rows of rollers and are used in various industrial applications. They are suitable for supporting heavy radial loads and can accommodate moderate axial loads in both directions. These bearings are often employed in machinery such as conveyors, crushers, and mills.

B. Spherical Roller Bearings with Tapered Bore

This type features a tapered inner bore, allowing for easier mounting on tapered shafts. The taper facilitates accurate alignment and provides a secure fit, which can be beneficial in applications where quick installation or removal is required. Spherical roller bearings with tapered bores are commonly used in agricultural machinery and heavy equipment.

C

. Spherical Roller Thrust Bearingstypes of spherical roller bearings

Designed to handle predominantly axial loads, spherical roller thrust bearings consist of a thrust plate, a shaft washer, and rollers arranged in a structure similar to standard spherical roller bearings. They are ideal for applications requiring high thrust capacity, such as in gearboxes and rotary tables.

D. Self-Aligning Spherical Roller Bearings

These bearings are a specialized type of spherical roller bearing that further enhances the ability to accommodate misalignment. They feature an extended spherical outer diameter and a unique internal geometry that allows for greater misalignment without increased wear. Self-aligning spherical roller bearings are ideal in applications where alignment may be an issue, such as in large electric motors or generators.

E. Spherical Roller Bearings with Special Coatings

To enhance performance and resistance to wear and corrosion, some spherical roller bearings come with specialized coatings like zinc or ceramic. These coatings prolong the bearings' lifespan and reliability, particularly in harsh environments, such as in the chemical industry or marine applications.

3. Applications of Spherical Roller Bearings

Spherical roller bearings find applications in a wide range of industries, including

- Mining and Construction Used in heavy machinery like excavators, loaders, and crushers, due to their ability to withstand extreme loads and harsh conditions. - Automotive Industry Utilized in axle bearings and gearboxes, where load alignment and balance are critical for performance and safety. - Cement Manufacturing These bearings support rotary kilns and grinding mills, which require robust components to handle high rotational speeds and heavy loads. - Renewable Energy In wind turbines, spherical roller bearings play a vital role in rotor and gearbox assemblies, contributing to the efficiency and reliability of energy production.

4. Advantages of Spherical Roller Bearings

- High Load Capacity They can support significant radial and axial loads, making them suitable for demanding applications. - Misalignment Tolerance Their design allows for angular misalignment, reducing the likelihood of premature bearing failure. - Versatility Spherical roller bearings can be used in various applications, making them a popular choice across multiple industries.

Conclusion

Spherical roller bearings are essential components in machinery that require reliable performance under challenging conditions. Their variety of types, each designed for specific applications, ensures that there is a suitable option for nearly every mechanical need. Understanding the different types and their respective advantages can aid engineers and technicians in selecting the right bearing to enhance the efficiency and longevity of their machinery.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025