Nov . 29, 2024 13:36 Back to list

Understanding the Functionality and Applications of Thrust Ball Bearings in Machinery

Understanding Thrust Ball Bearings A Comprehensive Overview

Thrust ball bearings are a vital component in many mechanical systems, designed to support axial loads while allowing smooth rotation. Unlike other types of bearings, such as radial ball bearings, which accommodate radial loads, thrust ball bearings are specifically engineered to handle thrust loads. This article delves into the construction, types, applications, advantages, and limitations of thrust ball bearings.

Construction and Types

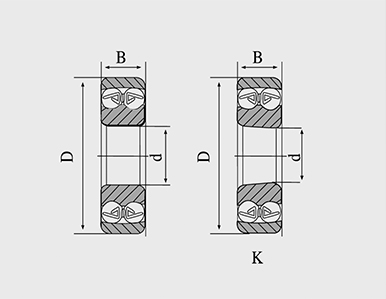

Thrust ball bearings consist of two grooved rings, known as races, and a set of balls that fit between these races. The design allows the balls to rotate freely while providing support for axial loads along the axis of the shaft. The primary types of thrust ball bearings include single-direction and double-direction ball bearings.

- Single-Direction Thrust Ball Bearings These bearings can withstand thrust loads in one direction only. They are commonly used in applications where the load is consistently applied from a single side. - Double-Direction Thrust Ball Bearings These bearings can bear loads from both directions, making them suitable for applications where the direction of the load may change frequently.

Applications

Thrust ball bearings are used in a variety of applications across numerous industries. Their ability to efficiently support axial loads makes them ideal for

1. Machine Tools In machines where axial motion is required, thrust ball bearings provide the necessary support and stability. 2. Automotive Applications In vehicles, these bearings are often found in gearboxes and other components that experience rotary motion constrained in a linear direction.

3. Industrial Equipment They are used in conveyor systems, cranes, and lifts, where efficient load transfer is crucial for performance.

thrust ball bearing

4. Aerospace Thrust ball bearings are utilized in aircraft engines and control systems where reliability and precision are paramount.

Advantages of Thrust Ball Bearings

Thrust ball bearings offer several advantages. Firstly, they provide excellent axial load support, which is crucial for the stability of rotating machinery. Their design allows for lower friction and faster movement compared to other bearing types, enhancing efficiency.

The ease of installation and maintenance is another significant benefit. Thrust ball bearings do not require complex alignments, making them relatively easy to integrate into mechanical systems. Additionally, they can handle moderate speeds effectively, making them versatile for various applications.

Limitations

Despite their advantages, thrust ball bearings do come with limitations. They are primarily suitable for moderate speeds and are not designed to support significant radial loads. If radial loads are present, additional bearings may be required to accommodate them, increasing overall system complexity.

Furthermore, the material of the bearings plays a crucial role in their performance. Thrust ball bearings are typically made from high-grade steel; however, in harsh operating environments, such as those with excessive moisture or corrosive substances, the bearings may be subject to wear and deterioration. Selecting the right type of bearing for specific conditions is essential to ensure longevity and reliability.

Conclusion

In summary, thrust ball bearings are indispensable components in modern machinery and engineering applications. Their unique design allows for effective support of axial loads, making them suitable for various industries, including automotive, aerospace, and manufacturing. Understanding their construction, advantages, and limitations is crucial for engineers and technicians when designing systems that require precise and reliable motion. As technology continues to advance, the development of new materials and designs for thrust ball bearings will likely enhance their performance, leading to even broader applications in the future.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025