Nov . 23, 2024 20:40 Back to list

taper roller bearing application

Applications of Taper Roller Bearings

Taper roller bearings are a crucial component in a wide variety of machinery and equipment, providing essential support for rotating shafts. Their design allows them to handle both axial and radial loads, making them versatile and effective for many applications. This article explores the numerous applications of taper roller bearings, detailing their functionality and the benefits they offer in different industries.

Overview of Taper Roller Bearings

Taper roller bearings consist of inner and outer rings that have tapered inner and outer raceways, and tapered rollers that fit between these raceways. The angle of the taper allows for a rolling motion that accommodates combined loads, where axial and radial forces need to be managed simultaneously. This unique design increases the bearing's load capacity, durability, and efficiency, making them preferred choices in demanding conditions.

Automotive Applications

One of the most significant applications of taper roller bearings is in the automotive industry. They play a critical role in vehicle wheel hubs, where they support the weight of the vehicle and ensure smooth wheel rotation. Taper roller bearings are also found in various drivetrain components, including differential gears and transmission systems. Their ability to handle heavy loads and resist wear makes them ideal for heavy-duty vehicles, such as trucks and buses, which require robust support for high-stress applications.

Industrial Machinery

In the realm of industrial machinery, taper roller bearings are commonly used in equipment such as conveyor systems, milling machines, and rotary tables. These bearings support rotating components that undergo significant operational stress, making their reliability vital for maintaining productivity. For instance, in manufacturing plants, taper roller bearings may be used in gearboxes, where they manage the transmission of power and help reduce friction, thereby increasing equipment lifespan.

Aviation and Aerospace

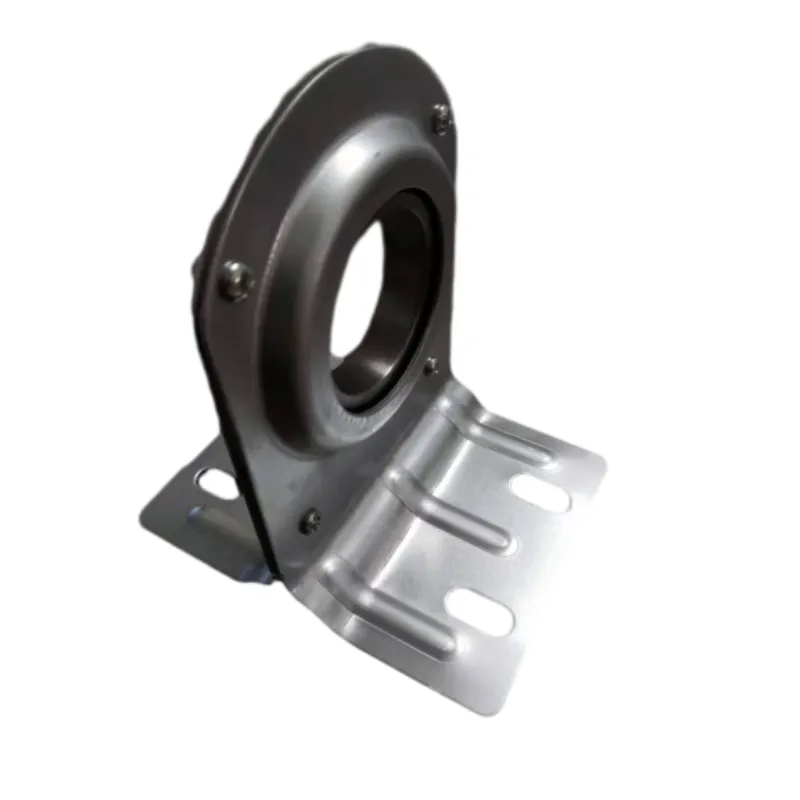

taper roller bearing application

The aviation and aerospace industries also rely heavily on taper roller bearings due to their high-performance characteristics. In aircraft, these bearings are utilized in landing gear assemblies and control surfaces where precision and reliability are paramount. The ability to withstand extreme forces and environmental conditions makes taper roller bearings suitable for these critical applications. Ensuring the safety and efficiency of aircraft requires components that can perform reliably under a variety of conditions, and taper roller bearings meet these stringent demands.

Construction Machinery

Construction machinery, such as excavators, cranes, and bulldozers, often operates in harsh environments with considerable loading conditions. Taper roller bearings help ensure smooth operation in these machines by supporting heavy components like pivot points and lifting arms. Their durability and capacity to handle axial loads under harsh conditions contribute to the machines’ operational effectiveness and longevity, ultimately leading to reduced maintenance costs and increased productivity on construction sites.

Railway Applications

Taper roller bearings are extensively used in railway systems, particularly in the wheelset assemblies of trains. They support the weight of the train while allowing for smooth, efficient rolling over tracks. The design of taper roller bearings minimizes friction and heat generation, which is critical for maintaining efficiency at high speeds. Additionally, their ability to endure heavy axial and radial loads enhances safety and reliability in railway operations.

Wind Energy

As renewable energy sources gain prominence, taper roller bearings are increasingly being employed in wind turbines. They are used in both the rotor and gearbox assemblies. The ability to handle variable loads and extreme weather conditions makes them well-suited for this application. Efficient operation of wind turbines is vital for maximizing energy production, and taper roller bearings contribute significantly to this goal by ensuring smooth and reliable performance.

Conclusion

Taper roller bearings are essential components in a multitude of applications across various industries. Their ability to handle combined loads makes them incredibly versatile, allowing their implementation in automotive, industrial machinery, aviation, construction, railway, and wind energy applications. As industries continue to evolve and demand higher performance and reliability from their machinery, taper roller bearings will remain a pivotal part of engineering solutions, driving efficiency and longevity in equipment performance.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025