Nov . 30, 2024 00:02 Back to list

Tapered Bearing Removal Tool for Easy and Efficient Component Extraction Solutions

Understanding Tapered Bearing Pullers Functions and Advantages

When it comes to mechanics, having the right tools can make all the difference in efficiency and effectiveness. One such specialized tool is the tapered bearing puller. This tool is designed specifically for extracting tapered bearings, which are commonly used in various automotive and industrial applications. Understanding the purpose, functionality, and advantages of tapered bearing pullers can enhance your toolbox and improve your mechanical projects.

What is a Tapered Bearing Puller?

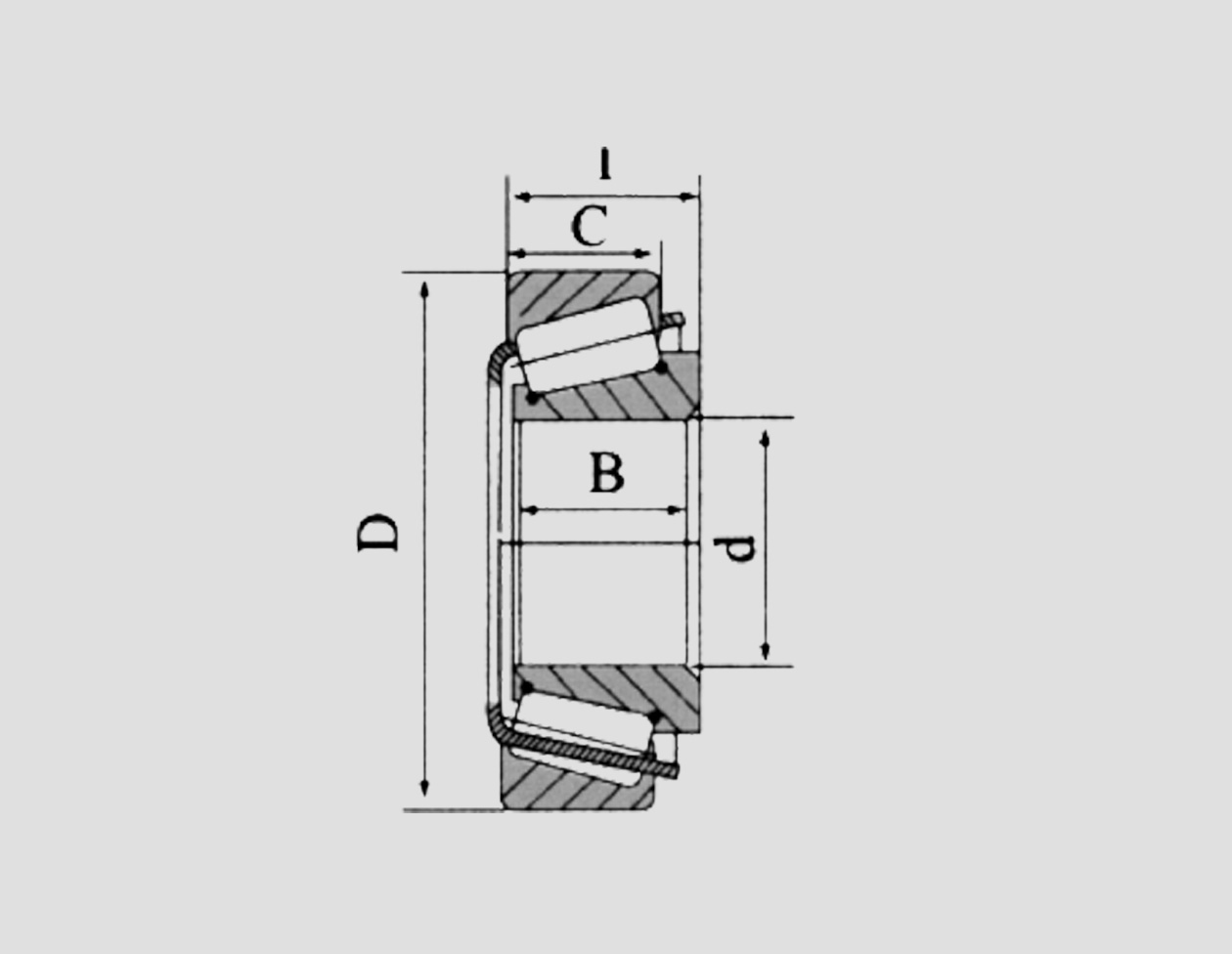

A tapered bearing puller is a mechanical tool used to remove tapered bearings from their housings or shafts without causing damage to the bearings or surrounding components. These pullers come in various sizes and designs, tailored to accommodate different bearing dimensions and access requirements. They typically feature three arms that grip the outer race of the bearing, and a central forcing screw that applies even pressure to pull the bearing away from the mounting surface.

How Does a Tapered Bearing Puller Work?

The operation of a tapered bearing puller is relatively straightforward. To use one, the mechanic must first ensure that the bearing puller is properly sized for the bearing they wish to extract. Once selected, the arms of the tool are positioned around the bearing, and the central screw is threaded into position. As the screw is turned, it pulls the arms inward, gripping the bearing’s outer race and applying a steady force. This force gradually separates the bearing from its seat, allowing for safe and effective removal.

Importance of Using a Tapered Bearing Puller

Using a tapered bearing puller is crucial for several reasons

1. Prevention of Damage Tapered bearings are precision components, and improper removal can cause deformation or surface damage. A puller ensures that the bearing is extracted evenly, preserving its integrity for potential reuse.

tapered bearing puller

2. Efficiency Attempting to remove a tapered bearing without the proper tool can lead to time-consuming trial and error. A puller streamlines the process, allowing mechanics to complete jobs more rapidly and efficiently.

3. Versatility Tapered bearing pullers can be used on a variety of machinery ranging from automotive applications to industrial equipment, making them a versatile addition to any mechanic’s toolkit.

Advantages of Tapered Bearing Pullers

The advantages of using a tapered bearing puller extend beyond mere functionality

- Cost-Effectiveness While there may be an upfront investment in a quality tapered bearing puller, the savings from preventing damage to bearings and surrounding parts can outweigh the costs. This longevity translates to fewer replacements and repairs over time.

- User-Friendly Most tapered bearing pullers are designed with ease of use in mind. The tools are often adjustable for a range of bearing sizes and feature simple mechanics that can be operated with minimal training.

- Reduced Downtime In commercial settings, time is money. Using a tapered bearing puller can significantly reduce downtime, facilitating quicker repairs and maintenance, and getting machinery back into operation faster.

Conclusion

In conclusion, a tapered bearing puller is an invaluable tool for anyone dealing with bearings in mechanical settings. Its role in efficiently and safely extracting tapered bearings cannot be overstated. By preventing damage and promoting effective removal, these pullers enhance the overall mechanics experience, save time, and reduce costs in the long run. Whether you're a seasoned mechanic or a home DIY enthusiast, investing in a quality tapered bearing puller is a step toward ensuring that your projects are both successful and sustainable. Ensure you have the right tool for the job, and experience the efficiency and reliability that a tapered bearing puller brings to your mechanical endeavors.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025