Dec . 18, 2024 01:18 Back to list

supply of multi-row cylindrical roller bearings for industrial use

Supply of Multi-Row Cylindrical Roller Bearings for Industrial Use

In the industrial sector, where machinery plays a pivotal role in various operations, the efficiency and reliability of these machines are paramount. One of the essential components contributing to this efficiency is the bearing system employed in industrial machinery. Among the numerous types of bearings available in the market, multi-row cylindrical roller bearings have gained significant traction due to their distinctive characteristics and advantages that cater to industrial needs.

Understanding Multi-Row Cylindrical Roller Bearings

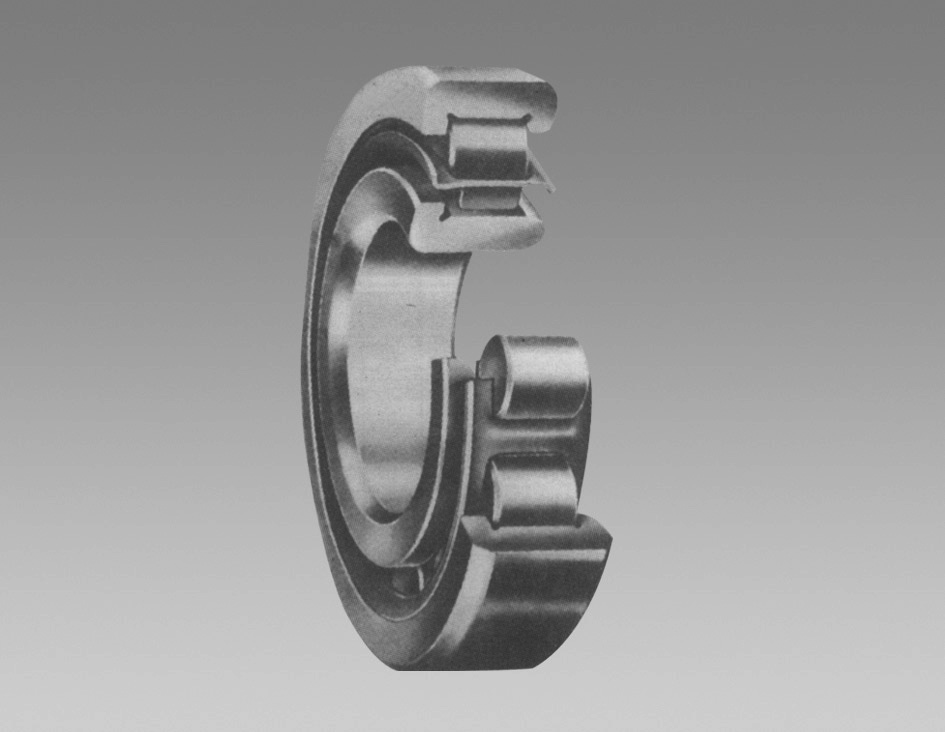

Multi-row cylindrical roller bearings consist of multiple rows of cylindrical rollers arranged in a way that allows for the accommodation of axial and radial loads. These bearings are designed to handle high loads and provide a high degree of stiffness, making them particularly suitable for heavy machinery and high-speed applications. They can be found in various industries, including mining, construction, manufacturing, and transportation.

The unique design of multi-row cylindrical roller bearings allows them to efficiently distribute loads across a larger surface area, significantly reducing stress on individual components. This characteristic not only enhances their load-carrying capacity but also extends their operational lifespan, reducing the frequency of maintenance and replacements. The bearings can handle misalignment and thermal expansion, making them robust options for challenging industrial environments.

The Demand for Multi-Row Cylindrical Roller Bearings

The global market for multi-row cylindrical roller bearings is on the rise, fueled by an increasing demand for highly efficient and reliable machinery components. Industries are striving for improved performance and longer operational life for their equipment, making high-quality bearings an essential investment.

Market trends indicate a growing inclination towards automation and advanced manufacturing processes, which further drives the need for durable and efficient bearing solutions

. As equipment manufacturers strive to produce machines that can withstand harsh operating conditions while maintaining precision, the reliance on multi-row cylindrical roller bearings is expected to grow in the coming years.supply of multi-row cylindrical roller bearings for industrial use

Supply Chain and Availability

The supply chain for multi-row cylindrical roller bearings is critical to meeting the demands of various industries. Manufacturers need to ensure a consistent and high-quality supply of bearings to maintain operational efficiency for their clients. This includes securing reliable sources of raw materials, maintaining quality control during the manufacturing process, and establishing logistical frameworks that allow for timely delivery and inventory management.

Global suppliers and manufacturers are increasingly investing in technology and automation to enhance production capabilities. The success of these suppliers is dependent on their ability to deliver products that meet industry standards and customer expectations for performance, durability, and reliability.

Challenges in the Market

Despite the positive outlook for multi-row cylindrical roller bearings, some challenges persist in the supply chain. Fluctuations in raw material prices, changes in demand patterns, and disruptions due to unforeseen circumstances (such as geopolitical tensions and natural disasters) can create bottlenecks in production and supply.

Additionally, the introduction of advanced materials and manufacturing techniques requires continual adaptation from suppliers to keep up with market demands. Manufacturers must also emphasize sustainability and environmental responsibility in their operations, as industries increasingly prioritize eco-friendly practices.

Conclusion

In conclusion, the supply of multi-row cylindrical roller bearings for industrial use is a vital component in the machinery market. Their ability to handle heavy loads and provide reliable service makes them an indispensable asset in various applications. As industries evolve and demand becomes more complex, suppliers must innovate and adapt to ensure a steady flow of quality bearings. In doing so, they will play a crucial role in enhancing the performance and longevity of industrial machinery, ultimately leading to increased productivity and efficiency across the sector. As we look to the future, the importance of these bearings will continue to be recognized, shaping the landscape of industrial operations worldwide.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025