Dec . 01, 2024 03:58 Back to list

spherical roller bearings

Understanding Spherical Roller Bearings Key Features and Applications

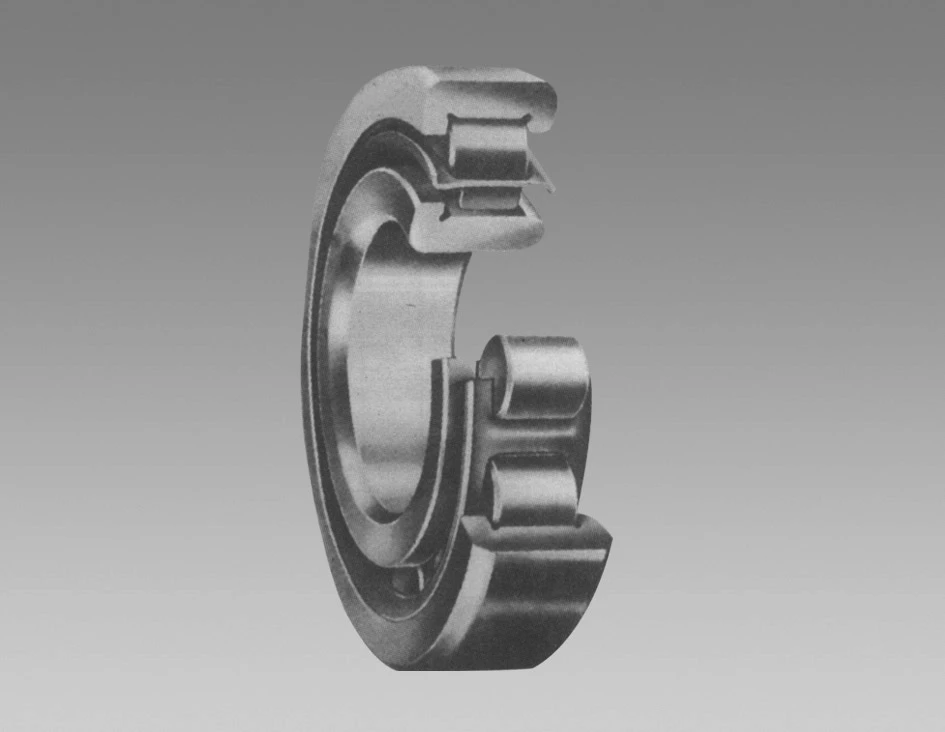

Spherical roller bearings are specialized rolling-element bearings designed to accommodate heavy loads and allow angular misalignment, making them an essential component in various industrial applications. These bearings are characterized by their ability to support both axial and radial loads due to their unique design that features a spherical outer raceway and barrel-shaped rollers.

Construction and Design

A typical spherical roller bearing consists of two rows of symmetrical rollers, a solid inner ring, and an outer ring with a spherical raceway. This construction not only provides a high degree of load-carrying capacity but also enables the bearing to self-align in the presence of misalignment caused by shaft deflections or housing tolerances. The spherical shape of the outer raceway allows the bearing to accommodate misalignment angles of up to 2 degrees, which is often encountered in heavy machinery and equipment.

Key Features

1. Load Capacity Spherical roller bearings are designed to support significant radial and axial loads, making them suitable for applications where heavy loads are common. Their large contact area helps distribute the load, reducing stress on individual components.

2. Misalignment Tolerance One of the most significant advantages of spherical roller bearings is their ability to handle misalignment. This feature is crucial in various applications where installation conditions might cause misalignment due to thermal expansions or mechanical edge cuts.

3. Durability and Longevity With proper lubrication and maintenance, spherical roller bearings can operate efficiently over long periods. Their robust design minimizes wear and tear, contributing to longer service life and reduced maintenance costs.

4. Versatility These bearings are available in a range of sizes and configurations, which enables their use in various applications — from large industrial machinery to specialized equipment like wind turbines and railway vehicles.

spherical roller bearings

Applications

Spherical roller bearings find applications across numerous industries due to their unique characteristics. Here are some notable examples

- Mining and Quarrying Spherical roller bearings are commonly used in conveyor systems, crushers, and screeners in the mining and quarrying industries. They handle heavy loads and resist harsh conditions, such as dust and moisture.

- Construction Equipment Equipment like excavators, bulldozers, and cranes often rely on spherical roller bearings for their support structures, pivot points, and moving components. Their ability to withstand shock loads and misalignment makes them ideal for these applications.

- Wind Turbines In renewable energy applications, particularly wind turbines, spherical roller bearings are critical for rotor support and blade pitch control systems. They ensure the smooth operation of these machines in varying environmental conditions.

- Railways Spherical roller bearings are used in train axles, providing the strength needed to support heavy loads while allowing for track irregularities.

Conclusion

Spherical roller bearings are indispensable in industries where heavy loads and misalignment are prevalent. Their unique design, which allows for high load capacity and misalignment tolerance, makes them a preferred choice for various applications. Additionally, their durability and versatility enable manufacturers to optimize performance while minimizing maintenance costs. As technology advances and industry demands evolve, the role of spherical roller bearings will likely expand, further solidifying their importance in modern machinery and equipment. Understanding their features, advantages, and various applications is crucial for engineers and technicians tasked with selecting the right bearing solutions for their specific needs.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025