Nov . 09, 2024 09:54 Back to list

Understanding Axial Load Capacity in Spherical Roller Bearings for Enhanced Performance

Understanding Spherical Roller Bearings and Their Ability to Handle Axial Loads

Spherical roller bearings are a type of rolling-element bearing that can accommodate both radial and axial loads in both directions. These bearings are particularly known for their versatility and robustness, making them a popular choice in various industrial applications. In this article, we will explore the characteristics and advantages of spherical roller bearings, particularly in relation to their ability to handle axial loads effectively.

Structure of Spherical Roller Bearings

Spherical roller bearings consist of an outer ring with a spherical raceway, an inner ring with two raceways, and barrel-shaped rollers. The unique geometry of these rollers allows them to align themselves with the outer ring regardless of misalignments that may occur due to assembly errors, shaft deflections, or operational stresses. This self-aligning capability is one of the primary reasons spherical roller bearings are favored in applications where misalignment is a possibility.

Axial Load Handling

One of the hallmark features of spherical roller bearings is their ability to take on axial loads, which are forces applied parallel to the shaft of the bearing. Unlike some other bearing types that are designed primarily for radial loads, spherical roller bearings excel in contexts where both radial loads and axial loads are present.

The design of the rollers allows for a high degree of contact with the raceway, increasing the bearing’s load-carrying capacity. They can manage axial loads in both directions, which enhances their versatility in applications such as heavy machinery, wind turbines, and conveyor systems. The ability to support axial loads effectively reduces the need to combine bearings, streamlining designs and reducing potential failure points.

Applications and Benefits

Industries that rely heavily on machinery with dynamic loads, such as construction, mining, and manufacturing, benefit significantly from the use of spherical roller bearings. They are commonly found in applications such as gearboxes, electric motors, and material handling equipment. The requirement for durability in these environments cannot be overstated, and spherical roller bearings are designed to handle the high forces encountered during operation.

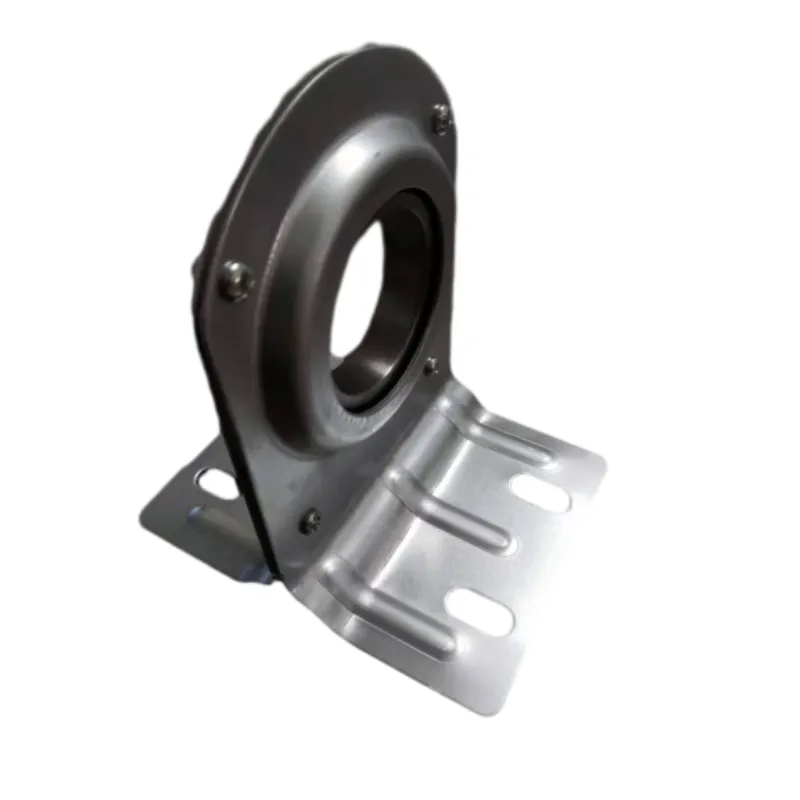

spherical roller bearing axial load

In addition to their mechanical robustness, the self-aligning feature of spherical roller bearings contributes to lower maintenance costs and longer service life

. This capability is particularly beneficial in environments where precise alignment is challenging to maintain, preventing premature wear and damage to both the bearings and the machinery they support.Factors Affecting Axial Load Performance

While spherical roller bearings are well-suited for handling axial loads, several factors influence their performance

1. Load Direction Spherical roller bearings can support axial loads in both directions but are more effective when loads are evenly distributed. Sudden or vertical directional changes in load can affect longevity.

2. Speed The rotational speed of the application can affect the heat generated within the bearing. High speeds may require additional lubrication or specialized bearing designs to manage thermal conditions.

3. Lubrication Proper lubrication is crucial for minimizing friction and wear. Some applications may necessitate specific lubricants that can withstand extreme conditions, thereby enhancing bearing life.

4. Environmental Conditions Exposure to contaminants, temperature extremes, or excessive moisture can impact the integrity of the bearing. Choosing the right materials and seals can mitigate these risks.

Conclusion

Spherical roller bearings play a vital role in modern machinery by effectively managing both radial and axial loads. Their unique design enables them to handle challenging operational conditions, making them indispensable in various industries. Understanding the advantages and limitations of these bearings, particularly regarding axial loads, is crucial for engineers and designers to optimize their applications and ensure reliability. As industries continue to evolve, the demand for efficient and durable bearing solutions will only grow, solidifying the role of spherical roller bearings in engineering applications worldwide.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025