Oct . 10, 2024 15:08 Back to list

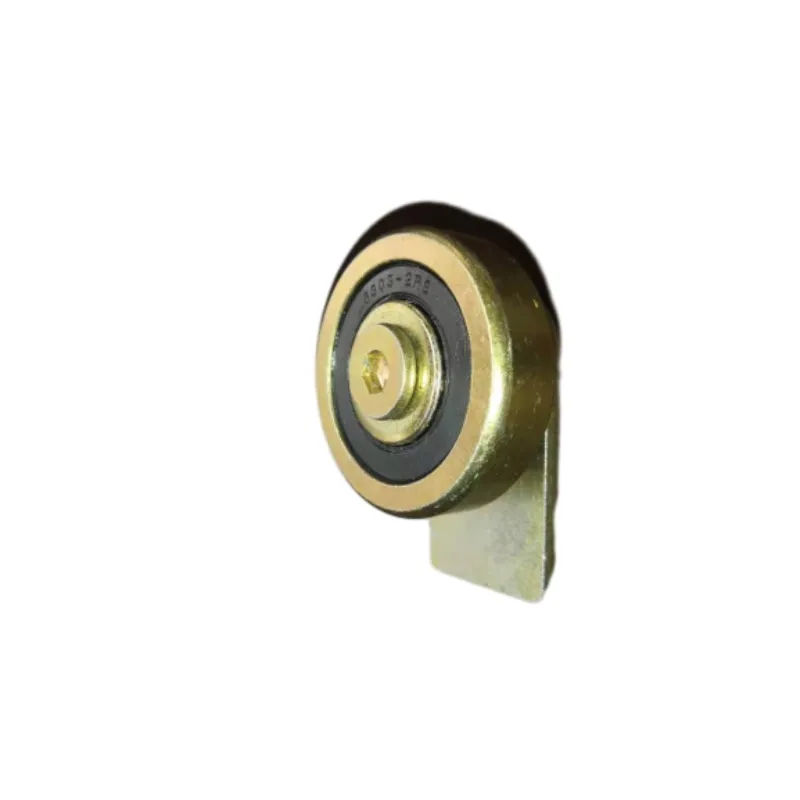

single row spherical roller bearing

Single Row Spherical Roller Bearings A Comprehensive Overview

Single row spherical roller bearings are pivotal components in a myriad of industrial applications, owing to their innovative design and capacity to bear heavy loads while accommodating misalignment. This article delves into the design, functionality, applications, and advantages of single row spherical roller bearings.

Design and Structure

Single row spherical roller bearings consist of an inner ring, an outer ring, and a set of spherical rollers. The unique geometry of the bearing allows the rollers to pivot freely within the raceways, which are slightly curved. This design enables the bearing to handle both radial and axial loads in either direction. The spherical shape of the rollers facilitates a greater contact area with the races, leading to improved load distribution and reduced stress on the bearing surfaces.

Typically, these bearings contain a cage or separator that maintains the proper spacing between the rollers, thus preventing them from colliding and allowing smooth operation. The cage is often made from materials such as steel or brass, chosen based on the specific application requirements.

Functionality

One of the key attributes of single row spherical roller bearings is their ability to accommodate misalignment due to shaft deflection and mounting errors. This feature is particularly valuable in high-load applications where slight misalignments are common. Furthermore, these bearings can operate efficiently in environments subjected to vibration and shock loads.

The rolling elements in spherical roller bearings are designed to reduce friction, which translates into lower operating temperatures and extended bearing life. Additionally, these bearings are typically self-aligning, meaning they can adjust themselves when the shaft shifts, which reduces wear and tear on associated components.

Applications

Single row spherical roller bearings are utilized across various industries due to their robust nature

. They are widely employed in applications such assingle row spherical roller bearing

1. Heavy Machinery These bearings are essential in cranes, excavators, and industrial gearboxes where heavy loads and misalignments are prevalent. 2. Mining and Construction Equipment in these industries often encounters harsh conditions, making the durability and resilience of spherical roller bearings crucial.

3. Automotive In vehicles, these bearings can be found in applications such as wheel hubs and transmission systems.

4. Wind Turbines The ability to handle dynamic loading and misalignment makes these bearings suitable for wind turbine gearboxes.

5. Cement and Steel Processing Machinery in these sectors frequently operates under severe conditions, where the reliability of spherical roller bearings is critical.

Advantages

The advantages of single row spherical roller bearings are manifold. Their ability to handle high radial and moderate axial loads makes them suitable for a diverse range of applications. Additionally, their self-aligning feature minimizes the risk of premature wear and failure, thereby increasing equipment lifespan and reliability.

Another noteworthy benefit is their capacity to operate in harsh environments, making them ideal for outdoor applications and industries that face dust, dirt, and moisture.

Their low maintenance requirements reduce operational downtime, which is a considerable advantage for industries that depend on high availability and efficiency. Moreover, the designs can be tailored with different materials and lubricants to cater to specific requirements, enhancing their versatility further.

Conclusion

In summary, single row spherical roller bearings are essential components that play a critical role in the functionality and longevity of various machinery and equipment. With their unique design that allows for heavy load capacity, self-alignment, and robust performance in challenging environments, these bearings are a reliable choice for many industrial applications. As industries continue to evolve and demand greater efficiency, the importance and relevance of single row spherical roller bearings will likely persist, ensuring their role as a cornerstone in engineering solutions worldwide.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025