Nov . 17, 2024 21:20 Back to list

single row deep groove ball bearings

Understanding Single Row Deep Groove Ball Bearings

Single row deep groove ball bearings represent one of the most common types of rolling element bearings used in various applications. Their design and versatility make them a staple in industries ranging from automotive to aerospace, household appliances to industrial machinery. In this article, we will delve into the characteristics, applications, advantages, and design considerations of single row deep groove ball bearings.

Characteristics of Single Row Deep Groove Ball Bearings

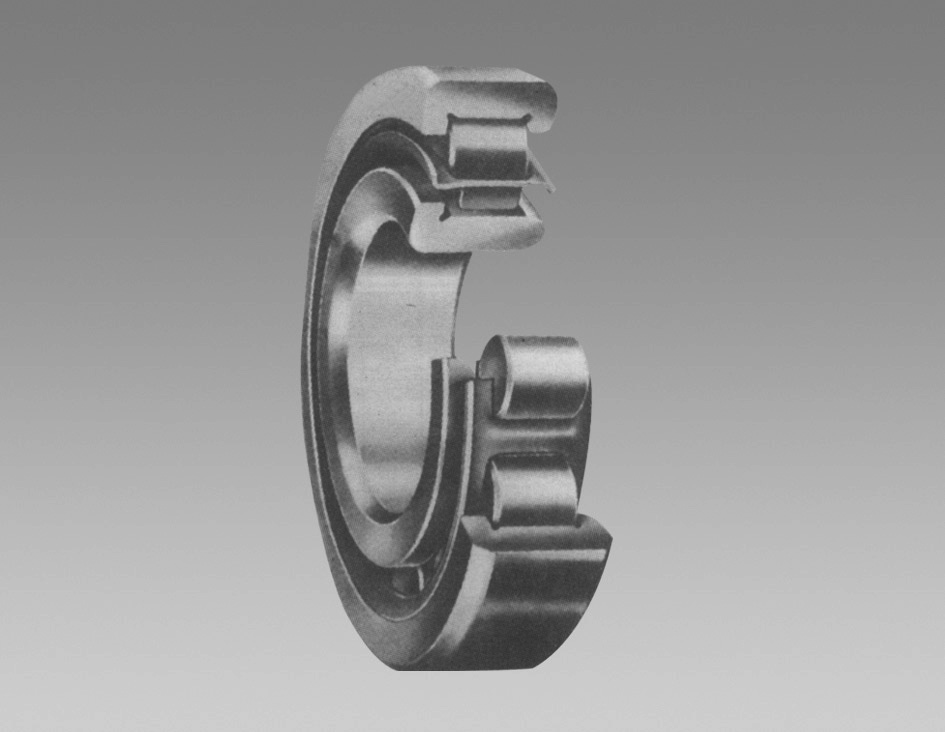

Single row deep groove ball bearings consist of an outer ring, an inner ring, a cage, and a series of balls. The design features a deep groove in both the outer and inner rings, which allows the balls to be firmly accommodated and provides a larger load-carrying capacity compared to other bearing types.

These bearings can operate effectively under various loads, including radial loads and axial loads in both directions. The deep groove design facilitates the smooth movement of the balls, leading to reduced friction and enhanced efficiency. Their construction allows for the bearings to be installed easily while requiring minimal space, making them a preferred choice in a range of compact applications.

Applications

The versatility of single row deep groove ball bearings makes them suitable for numerous applications across different sectors

. In the automotive industry, they are used in wheel hubs, electric motors, gearboxes, and pumps. Their ability to withstand high speeds and loads makes them ideal for critical automotive components that require reliable performance.In industrial settings, these bearings are commonly employed in conveyor systems, pumps, fans, and electric motors. They are also found in household appliances such as washing machines, refrigerators, and air conditioners. Their reliability and efficiency contribute directly to the performance and longevity of these devices.

Moreover, single row deep groove ball bearings play a vital role in the aerospace sector, where they are utilized in aircraft engines and auxiliary systems. The bearings are engineered to handle extreme operating conditions, ensuring the safety and reliability of aviation components.

Advantages of Single Row Deep Groove Ball Bearings

single row deep groove ball bearings

One of the primary advantages of single row deep groove ball bearings is their robustness and durability. They can accommodate misalignment and are less sensitive to installation errors, which means that they can perform well even under unfavorable conditions.

These bearings also require minimal maintenance, providing significant cost savings over their lifecycle. Their low friction design translates to reduced energy consumption, which is essential, especially in applications like electric motors where efficiency is paramount. Additionally, their capacity to handle both radial and axial loads makes them adaptable to a variety of mechanical situations.

Another significant benefit is their availability in numerous sizes and configurations. Manufacturers offer options with different materials, seals, and lubrication types, allowing for tailored solutions that meet specific operational requirements.

Design Considerations

When selecting a single row deep groove ball bearing, several design considerations must be taken into account. The load capacity, speed rating, and environmental conditions are crucial factors in determining whether a particular bearing is suitable for a specific application.

The choice of material also plays a pivotal role; while standard steel bearings are common, stainless steel and ceramic options are available for environments where corrosion and wear resistance are critical. Sealed or shielded bearings provide added protection against contaminants, which is essential in harsh working environments.

Lastly, precise lubrication is crucial for the performance and longevity of the bearings. Depending on the application, users can choose from different lubrication methods, including grease-filled, oil-filled, or self-lubricating options.

Conclusion

Single row deep groove ball bearings are a foundational element in modern machinery and equipment. Their ability to accommodate various loads, coupled with their durability and low maintenance requirements, make them an ideal choice for a broad range of applications. By understanding their characteristics, advantages, and design considerations, engineers and manufacturers can choose the right bearings to ensure optimal performance, reliability, and efficiency in their systems. Whether in automotive, industrial, or aerospace applications, these bearings continue to be an essential component driving technological advancements and productivity improvements.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025