Aug . 29, 2024 23:29 Back to list

Single Row Tapered Roller Bearing - High Performance & Durability

Understanding Single Row Tapered Roller Bearings

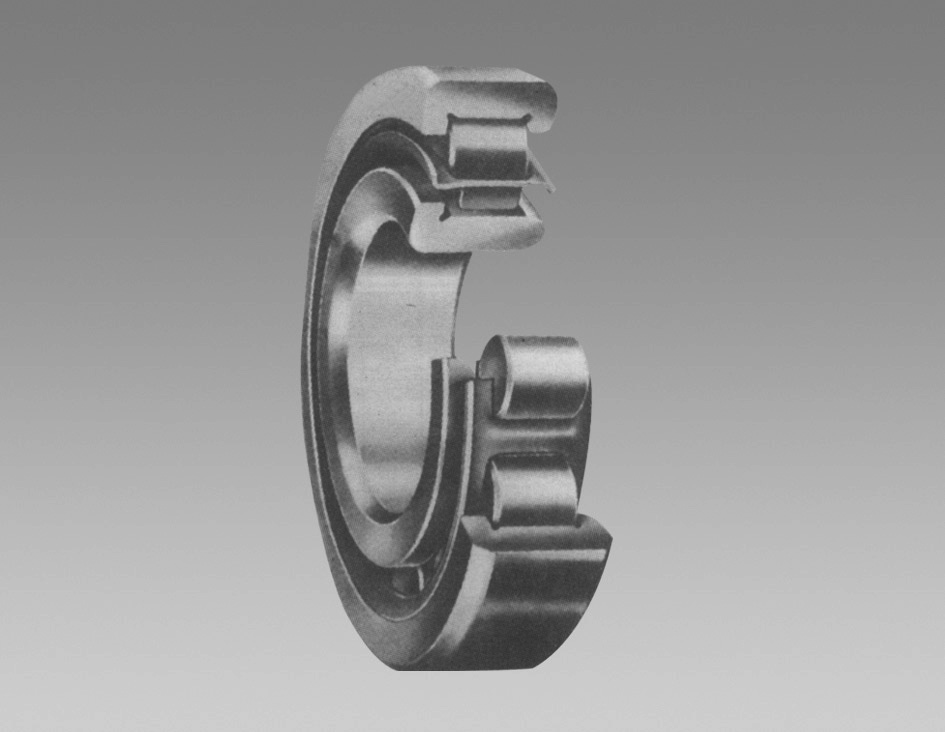

Single row tapered roller bearings are essential components widely used in a variety of mechanical applications. Known for their unique design and superior load-carrying capacity, these bearings are designed to support both radial and axial loads, making them versatile and highly efficient in operation.

The primary feature of a tapered roller bearing is its tapered rolling elements, which are arranged between the inner and outer rings. This conical shape allows the bearing to accommodate higher loads while maintaining low friction, thereby enhancing the efficiency of the machinery in which they are used. The single row design refers to the arrangement of rollers in a single row, which is suitable for applications where space is limited and moderate load support is required.

One of the key advantages of single row tapered roller bearings is their ability to handle combined loads. The angle of the tapered rollers helps distribute the load evenly, reducing stress on the bearing and increasing its service life. This makes them particularly suitable for applications such as automotive wheel hubs, gearboxes, and industrial machinery.

single row tapered roller bearing

Installation and maintenance of single row tapered roller bearings are relatively straightforward. Proper alignment during installation is crucial to ensure optimal performance and longevity. Regular inspections can help identify wear and prevent premature failure, making it essential for operators to monitor these bearings regularly.

Furthermore, these bearings come in various materials and designs, each suited for different environmental conditions and load types. For example, while standard steel is commonly used, some bearings are made from stainless steel or specialized materials to enhance corrosion resistance and durability in harsh environments.

In summary, single row tapered roller bearings play a vital role in modern machinery, offering significant advantages in load capacity and efficiency. Their ability to handle combined loads makes them suitable for various applications across industries. By understanding their features and proper maintenance, users can harness the full potential of these bearings, ensuring reliable performance and extended service life in their equipment.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025