Nov . 25, 2024 10:54 Back to list

Understanding the Components of a Tapered Roller Bearing and Their Functions

Understanding the Parts of a Tapered Roller Bearing

Tapered roller bearings are widely utilized in various applications, including automotive and industrial machinery, due to their ability to support both axial and radial loads. Understanding the individual components of a tapered roller bearing is essential for proper installation, maintenance, and troubleshooting.

Key Components

1. Outer Ring The outer ring, or raceway, is typically cylindrical with a conical shape that accommodates the tapered rollers. It forms the outer boundary of the bearing assembly and provides the mounting surface for the bearing into the housing. The design allows for optimal load distribution across the rollers, enhancing the bearing's performance and lifespan.

2. Inner Ring The inner ring is also conical and is fitted onto the shaft. Like the outer ring, it has a tapered surface that guides the rollers. The inner ring is essential for controlling the axial position of the bearing during operation, ensuring stability under load.

3. Tapered Rollers The tapered rollers are the heart of the bearing, designed to handle both axial and radial loads. Each roller is wedged in a manner that allows it to roll smoothly within the raceways. The tapered design permits the distribution of load over a larger contact area, which prolongs the bearing’s life and enhances reliability.

4. Cage (Separator) The cage is a crucial component that retains the tapered rollers in place and ensures even spacing between them. This separation minimizes friction and wear, allowing the rollers to move freely while maintaining their alignment in the raceways. The cage is typically made of steel, plastic, or brass, depending on the application’s needs.

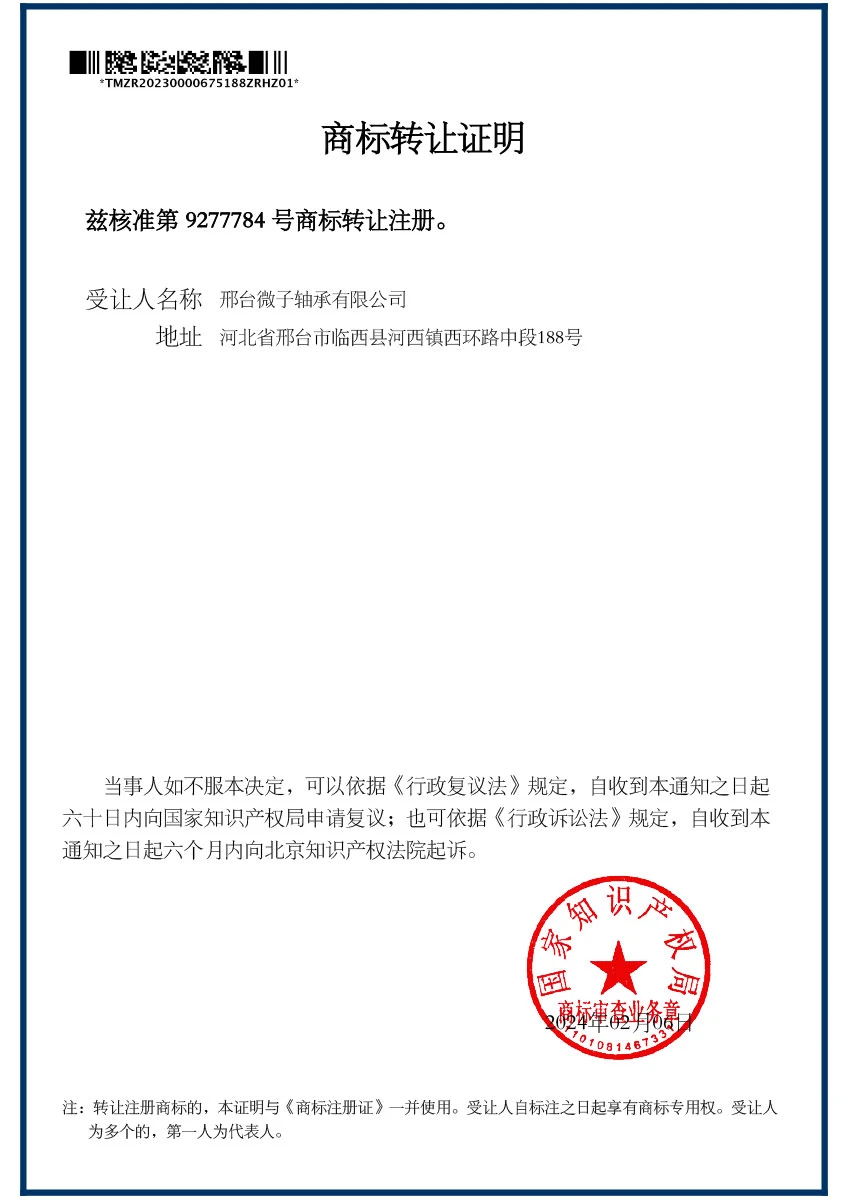

parts of a tapered roller bearing

5. Seals and Shields While not always a part of the tapered roller bearing itself, seals or shields are often included to protect the internal components from contaminants such as dirt, dust, and moisture. They also help retain lubrication within the bearing. The choice between seals or shields depends on the operational environment and the level of protection required.

Functionality and Applications

Tapered roller bearings excel in applications where there are both radial and axial loads, making them ideal for use in wheel bearings of vehicles, heavy machinery, and conveyor systems. Their unique design allows them to carry large amounts of load while also facilitating smooth rotation, which is critical in high-speed applications.

The ability to handle combined loads makes tapered roller bearings essential in many sectors, including automotive, aerospace, and manufacturing industries. Proper selection and maintenance of these bearings can lead to enhanced performance and reduced downtime.

Conclusion

In summary, understanding the parts of a tapered roller bearing is vital for anyone involved in machinery design, maintenance, or engineering. Each component, from the outer and inner rings to the tapered rollers and cage, plays a crucial role in the bearing’s overall functionality and effectiveness. By ensuring proper selection, installation, and maintenance of tapered roller bearings, industries can significantly improve their operational efficiency and equipment longevity.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025