Oct . 02, 2024 16:29 Back to list

nu cylindrical roller bearing

Understanding NU Cylindrical Roller Bearings A Comprehensive Overview

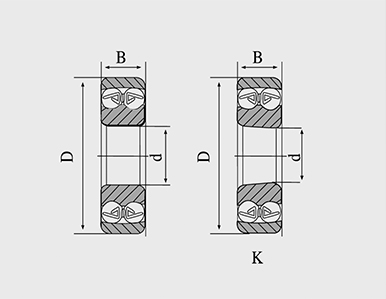

Cylindrical roller bearings are essential components in various mechanical applications, supporting heavy radial loads while maintaining high speeds. Among the diverse types of cylindrical roller bearings, the NU cylindrical roller bearing stands out for its unique design features and performance characteristics. This article delves into the structure, advantages, applications, and maintenance of NU cylindrical roller bearings, providing insights into why they are favored in numerous industries.

Structure and Design

The NU cylindrical roller bearing consists of an outer ring, an inner ring, and a set of cylindrical rollers. One of the defining features of NU bearings is that both rings are separable; this means they can be easily assembled and disassembled. The rollers in NU bearings are arranged in such a way that they only exert radial loads, making them ideal for applications where axial movement should be minimal. The inner ring is designed to have a smooth surface that guides the rollers, thereby minimizing friction and wear during operation.

Additionally, NU cylindrical roller bearings are designed with a cylindrical bore, allowing them to accommodate slight misalignments and axial displacement between the shaft and the housing. This flexibility is crucial in real-world applications, as it helps prolong the service life of the bearing.

Advantages of NU Cylindrical Roller Bearings

One of the primary advantages of NU cylindrical roller bearings is their load-carrying capacity. Due to the large surface area of the cylindrical rollers, these bearings can handle higher radial loads compared to other bearing types, such as ball bearings. This capacity makes them suitable for heavy-duty applications, including motors, transmissions, and construction equipment.

nu cylindrical roller bearing

Another significant advantage is the reduced frictional heat generated during operation. This characteristic leads to improved efficiency and can help extend the lifespan of both the bearing and the machinery it supports. Additionally, NU bearings can often operate at higher speeds, making them a preferred choice in industries where speed is critical.

Applications

NU cylindrical roller bearings are widely used across various sectors. In the automotive industry, they are employed in engines, gearboxes, and wheel hubs. Their robust design also makes them suitable for applications in machinery, such as milling machines and lathes, where heavy loads and high speed are common.

In the mining and construction sectors, these bearings support equipment like crushers and excavators, where durability and reliability are paramount. Their ability to withstand harsh conditions, dirt, and extreme temperatures further enhances their appeal in these demanding environments.

Maintenance and Care

Proper maintenance of NU cylindrical roller bearings is crucial to ensure optimal performance and longevity. Regular inspection for signs of wear, adequate lubrication, and monitoring operating temperatures can help prevent premature failure. Employing appropriate sealing solutions can also deter contamination, further enhancing the bearing’s durability.

In conclusion, NU cylindrical roller bearings are a pivotal component in various mechanical systems, thanks to their unique design and impressive load-carrying capacity. Their advantages, including reduced friction and high-speed capability, make them indispensable in many industries. Understanding their structure and maintenance needs is essential for maximizing their performance and longevity, ensuring successful outcomes in various applications.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025