Nov . 28, 2024 14:20 Back to list

Compact Thrust Ball Bearings for Precision Engineering Applications and Performance Optimization

Understanding Miniature Thrust Ball Bearings A Comprehensive Overview

Miniature thrust ball bearings are essential components in the design and function of many mechanical systems, providing crucial support and facilitating smoother motion in applications where space is limited. These bearings, characterized by their small size and high precision, play a vital role in numerous industries, including automotive, aerospace, robotics, and electronics.

What Are Miniature Thrust Ball Bearings?

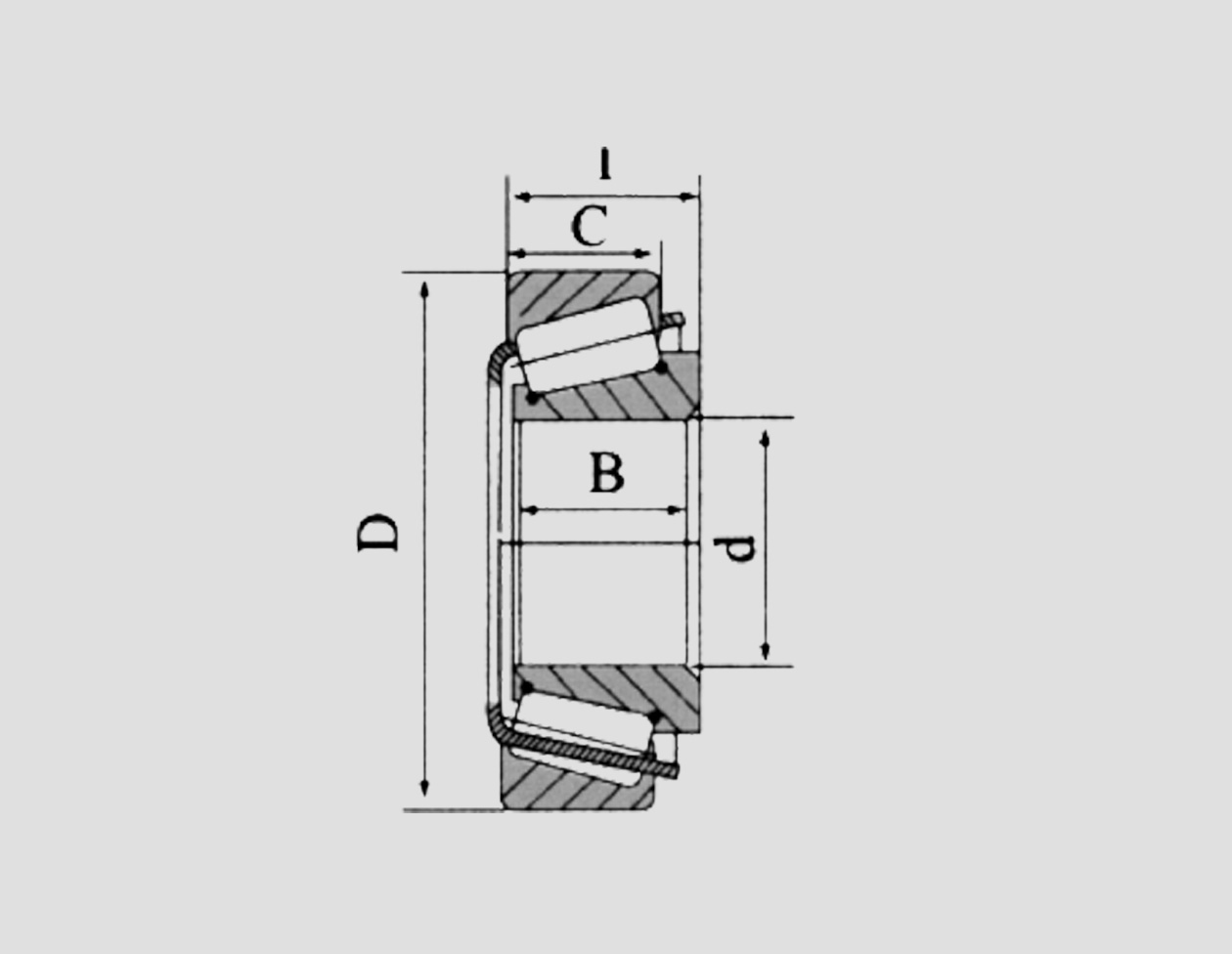

Miniature thrust ball bearings are typically composed of two grooved rings, known as races, and a set of balls. The design allows the balls to roll between the races, accommodating axial loads while minimizing friction. Unlike radial ball bearings, which manage loads in a radial direction, thrust bearings specifically handle loads in an axial direction. Their miniature size makes them particularly suitable for compact devices and systems.

The construction of these bearings usually involves high-quality materials such as stainless steel, which offers durability and resistance to corrosion. Some manufacturers may also use polymers or ceramic materials to enhance performance under specific conditions.

Key Features and Benefits

1. Compact Design Miniature thrust ball bearings are designed to occupy minimal space, making them ideal for applications with stringent size constraints. Their small footprint enables engineers to design more compact products, which is crucial in many modern technologies.

2. High Load Capacity Despite their small size, these bearings can support a significant amount of axial load. The precise arrangement of the balls within the races allows for even distribution of load, which enhances their performance and longevity.

3. Reduced Friction and Wear The design of miniature thrust ball bearings helps minimize friction, which is essential for efficient operation. Lower friction correlates with reduced wear, leading to longer service life and decreased maintenance costs over time.

miniature thrust ball bearing

4. Versatility These bearings can be used in a wide array of applications, from small motors and drives to higher precision instruments. Their adaptability makes them essential in various industries, including medical devices, consumer electronics, and automotive components.

Applications of Miniature Thrust Ball Bearings

Miniature thrust ball bearings are found in multiple applications across diverse sectors

- Robotics In robotic arms and mechanisms, these bearings provide support for rotating joints, ensuring that movements are smooth and precise. Their ability to manage axial loads is critical in precision-driven tasks.

- Aerospace In aerospace applications, the reliability and light weight of miniature thrust ball bearings are essential. They are often used in actuators and other components where axial loading is a significant factor.

- Electronics Many electronic devices, such as hard drives and computer fans, utilize miniature thrust ball bearings to enhance performance while ensuring quiet operation. Their small size also allows for intricate designs in electronic systems.

- Medical Devices In the medical field, precision is paramount. Miniature thrust ball bearings are employed in equipment such as surgical instruments and diagnostic machines, where they provide reliability and enhance the performance of critical mechanisms.

Conclusion

Miniature thrust ball bearings are remarkable engineering solutions that play a pivotal role in enabling efficient and reliable motion in a variety of applications. Their compact size, ability to support axial loads, and excellent performance characteristics make them indispensable in modern technology. As industries continue to innovate and push the boundaries of design, the importance of these miniature components will only increase. Understanding their features, benefits, and applications allows engineers and designers to incorporate them effectively, leading to advancements in numerous fields and enhancing the functionality of products used in everyday life.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025