Jan . 06, 2025 15:49 Back to list

machinery bearings

Delve into the pivotal role of machinery bearings, components that might appear simple but underpin much of the industrial world's efficiency and productivity. Machinery bearings are integral in reducing friction between moving parts in various types of machinery, from automotive engines to assembly line conveyors, ensuring smooth operations and enhancing the lifespan of equipment. Selecting the right bearing is critical, as it can significantly impact the performance and reliability of the machinery.

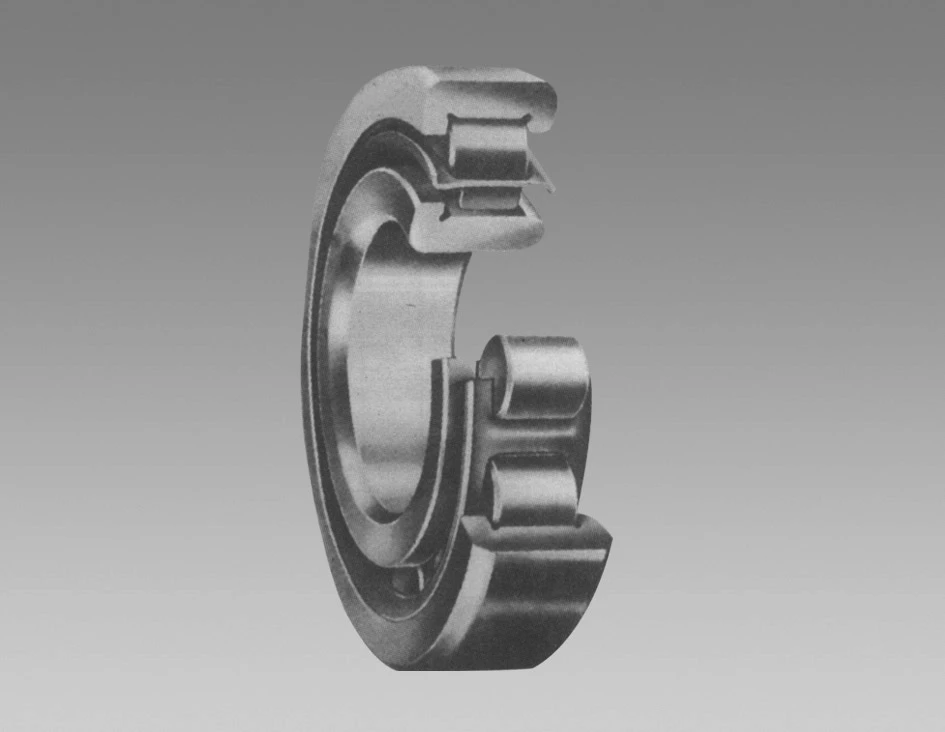

Understanding the broad categories of bearings is essential for making informed decisions. Primarily, bearings are classified into ball bearings and roller bearings, each designed for specific applications based on load type and operational conditions. Ball bearings are favored for applications requiring lower friction and higher speed, whereas roller bearings, with their increased contact area, are better suited for heavier loads and more challenging environments.

When it comes to expertise in selecting the appropriate bearing, it's crucial to consider the operating conditions to which the bearing will be subjected. These include factors such as load capacity, speed, temperature, and environmental conditions. For example, in situations involving high rotational speeds, a ball bearing, renowned for its low friction, would be ideal. Conversely, environments with heavy radial loads would benefit from the stability that roller bearings provide.

The credibility of the manufacturer or supplier is another essential factor. Trustworthy sources provide high-quality bearings that conform to industry standards, ensuring durability and efficiency. Bearings crafted with precision offer reduced wear and tear, leading to extended service life and, therefore, cost savings in the long run. Furthermore, reliable suppliers often offer technical support and guidance, reinforcing their role as authoritative figures in the field.

machinery bearings

Expert installation and maintenance of machinery bearings enhance their performance. Industry best practices suggest regular inspections and lubrication to mitigate the wear caused by friction. Adopting a proactive maintenance regime can preempt catastrophic failures, thus safeguarding the machinery and preventing costly downtimes.

A case study exemplifies the significance of choosing the right bearing. A manufacturing plant aiming to enhance the efficiency of its conveyor system opted for ceramic ball bearings. These bearings, known for their resistance to heat and corrosion, proved to be a transformative choice, enabling the conveyor to operate at higher speeds with greater reliability. This change drastically reduced downtime, increased production rates, and reasserted the importance of informed bearing selection.

Technological advancements further drive the domain of machinery bearings. Innovations such as self-lubricating bearings and smart bearings equipped with sensors for real-time condition monitoring are revolutionizing the industry. These advanced bearings not only reduce maintenance costs but also provide critical data, aiding in predictive maintenance and enhancing overall operational efficiency.

In summary, machinery bearings, though often overlooked, are a cornerstone of industrial reliability and efficiency. Expertise in selecting the right bearing type and ensuring reliable sources and proper maintenance practices can significantly enhance machinery performance. As technology progresses, remaining abreast of the latest developments in bearing technology promises even greater efficiencies and innovations. The strategic selection and maintenance of machinery bearings not only deliver immediate operational benefits but also lay the foundation for long-term industrial success.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025