Nov . 16, 2024 23:46 Back to list

m88010 bearing

Understanding the M88010 Bearing An Essential Component in Modern Machinery

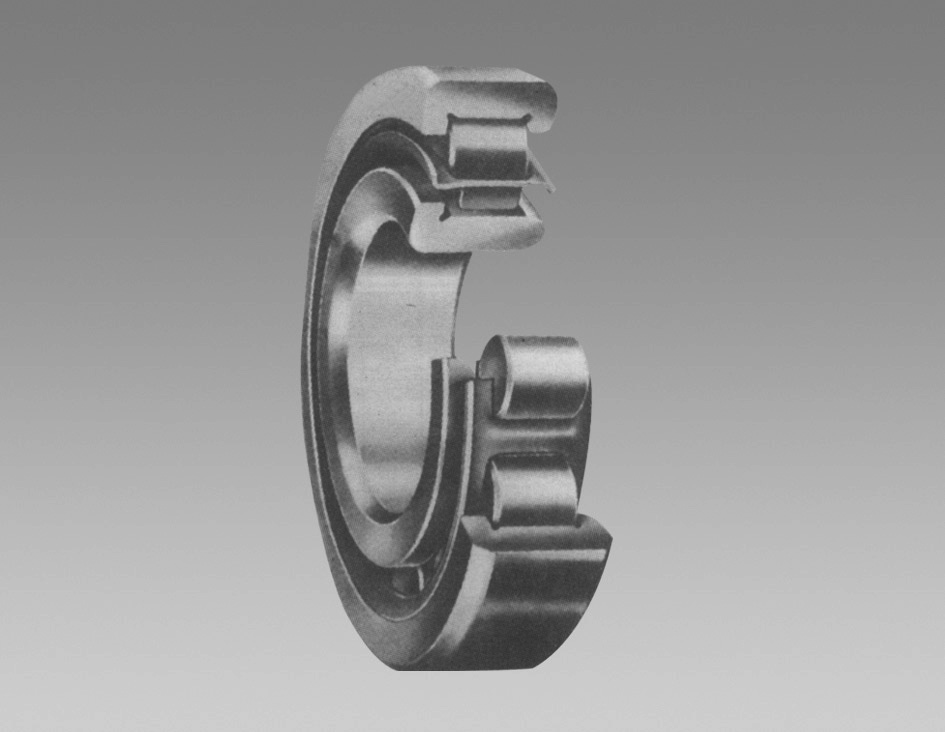

Bearings are integral components in various machinery, providing necessary support and reducing friction between moving parts. The M88010 bearing, in particular, stands out due to its unique design and versatile applications. This article explores the characteristics, applications, and maintenance of the M88010 bearing, shedding light on why it is a preferred choice in numerous industries.

Characteristics of the M88010 Bearing

The M88010 bearing is a type of tapered roller bearing, which is specifically designed to accommodate both radial and axial loads. Its construction typically features an outer race, an inner race, and tapered rollers arranged in a manner that allows for minimal friction and enhanced load distribution. One of the defining characteristics of the M88010 bearing is its ability to handle high-speed rotations while maintaining stability under load. This makes it ideal for applications where performance and reliability are paramount.

The design of the M88010 bearing also promotes longevity. High-quality materials, such as chrome steel or stainless steel, are commonly used in its manufacture, providing resistance to wear and corrosive environments. Additionally, the precision engineering involved in its production ensures a tight tolerance, allowing for smoother operation and reduced noise levels.

Applications of the M88010 Bearing

The versatility of the M88010 bearing makes it suitable for a wide array of applications across different sectors. In the automotive industry, it is used in wheel hubs, transmissions, and engines, where it aids in optimizing performance and durability. The bearing’s ability to handle substantial loads while allowing for angular misalignment makes it a popular choice in heavy-duty vehicles.

m88010 bearing

In industrial machinery, the M88010 bearing is commonly found in conveyor systems, pumps, and compressors. Its role in these systems is crucial, as it supports the rotational aspects of machinery, leading to efficient operation and reduced maintenance needs. Furthermore, its robust design ensures that it can withstand the rigorous conditions often encountered in manufacturing settings.

The M88010 bearing also plays a vital role in the agricultural sector, being utilized in various equipment such as tractors and harvesters. By providing reliable support and facilitating smooth operations, it contributes to increased productivity and efficiency in agricultural processes.

Maintenance of the M88010 Bearing

To ensure the optimal performance and longevity of the M88010 bearing, regular maintenance is essential. Proper lubrication is crucial to minimize friction and wear. Depending on the application, different types of lubricants—such as grease or oil—may be used. It is important to follow manufacturer guidelines regarding lubrication intervals and quantities.

Additionally, routine inspections should be conducted to identify signs of wear or damage. This may include checking for abnormal noises, overheating, or play in the bearing assembly. Early detection of issues allows for timely repairs or replacements, preventing costly downtimes and prolonging the life of the equipment.

In conclusion, the M88010 bearing is a vital component that enhances the performance and reliability of various machinery across multiple industries. Its robust design, ability to handle diverse loads, and suitability for high-speed operations make it an excellent choice for engineers and manufacturers. By understanding its characteristics and applications, and by implementing proper maintenance practices, industries can ensure that their operations run smoothly and efficiently, ultimately leading to greater productivity and success.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025