Nov . 19, 2024 22:48 Back to list

Design and Applications of Large Tapered Roller Bearings for Heavy-Duty Machinery

Understanding Large Tapered Roller Bearings Design, Applications, and Benefits

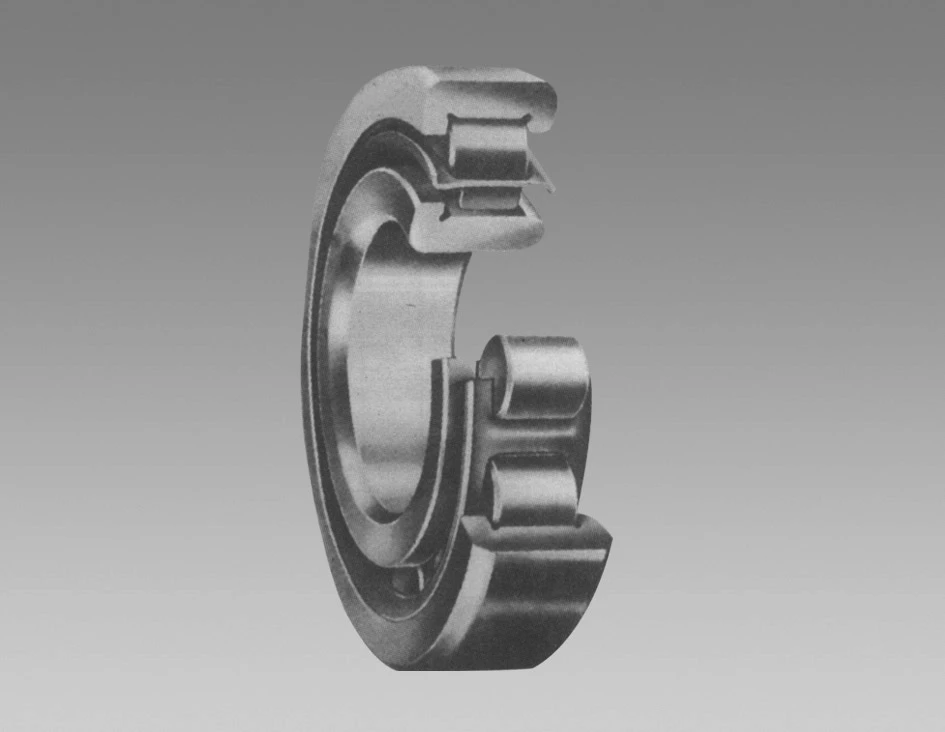

Large tapered roller bearings are critical components in many industrial applications, offering support for heavy loads while allowing for rotational movement. Their unique design features taper-shaped rollers that allow for the distribution of loads across a larger surface area, making them ideal for applications where weight and dynamic forces are significant considerations. This article delves into the design, applications, and benefits of large tapered roller bearings.

Design Features

Tapered roller bearings are composed of four main components the inner ring, outer ring, rollers, and a cage. The rollers are tapered, which allows for optimal contact with both the inner and outer raceways. This design enhances the mechanical efficiency and load capacity of the bearing. The taper angle is carefully engineered to ensure that the load is evenly distributed across the contact surfaces, reducing wear and extending the bearing's lifespan.

One of the major advantages of large tapered roller bearings is their ability to support both radial and axial loads. This dual capability makes them versatile for various applications where such loads are present. Moreover, these bearings are often designed with precision manufacturing techniques that further enhance their performance and reliability. Advanced materials, such as high-quality steel or ceramic, are often used to withstand severe operating conditions and corrosive environments.

Applications

Large tapered roller bearings are widely used in various industries, including

1. Automotive In the automotive sector, these bearings play a critical role in wheel hubs, differential assemblies, and transmission systems. They provide the necessary strength and stability for vehicles, ensuring a smooth ride.

2. Construction and Mining Heavy machinery, such as excavators, bulldozers, and trucks, rely on large tapered roller bearings to operate efficiently under harsh conditions. These bearings can handle significant radial and axial loads, making them suitable for equipment that experiences substantial wear and tear.

3. Aerospace In the aerospace industry, large tapered roller bearings are utilized in landing gear and engine components. The high reliability and performance under extreme conditions are crucial for ensuring the safety and efficiency of aircraft operations.

4. Shipbuilding Large marine vessels employ these bearings in propeller shafts and gearboxes, where they must endure challenging marine environments while supporting heavy loads.

large tapered roller bearings

5. Energy Sector Wind turbines are another application where large tapered roller bearings are essential. They assist in the smooth rotation of turbine blades, ultimately contributing to the efficiency of energy conversion processes.

Benefits

The advantages of using large tapered roller bearings extend beyond their load-bearing capabilities. Some key benefits include

- High Load Capacity The design of tapered roller bearings allows them to carry significant loads while reducing the risk of deformation and fatigue.

- Versatility Their ability to accommodate both axial and radial loads makes them suitable for a variety of applications across different industries.

- Reduced Maintenance With their robust construction and ability to withstand harsh environments, large tapered roller bearings often require less maintenance compared to other types of bearings, leading to reduced downtime in industrial settings.

- Enhanced Performance Due to their precision-engineered design, these bearings contribute to the overall performance of machinery and equipment, resulting in improved operational efficiency.

- Extended Service Life High-quality materials and manufacturing processes ensure that large tapered roller bearings can operate effectively for extended periods, providing cost savings for businesses through reduced replacement frequency.

Conclusion

Large tapered roller bearings are indispensable in modern engineering and manufacturing. Their unique design, coupled with significant load-bearing capabilities, makes them suitable for a wide range of applications, from automotive to heavy machinery. Understanding their features, benefits, and applications helps industries make informed choices in selecting the right bearings for their specific needs. As technology advances, the importance and application of these bearings will likely continue to grow, driving innovation and efficiency across multiple sectors.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025