Nov . 06, 2024 03:55 Back to list

Understanding FAG Taper Roller Bearings for Enhanced Performance and Durability

FAG Taper Roller Bearings An Overview

Taper roller bearings are essential components in various machinery and automotive applications, valued for their ability to support both radial and axial loads. Among the leading manufacturers of taper roller bearings is FAG, a brand synonymous with quality and innovation in the bearing industry. This article will delve into the features, applications, and benefits of FAG taper roller bearings.

What Are Taper Roller Bearings?

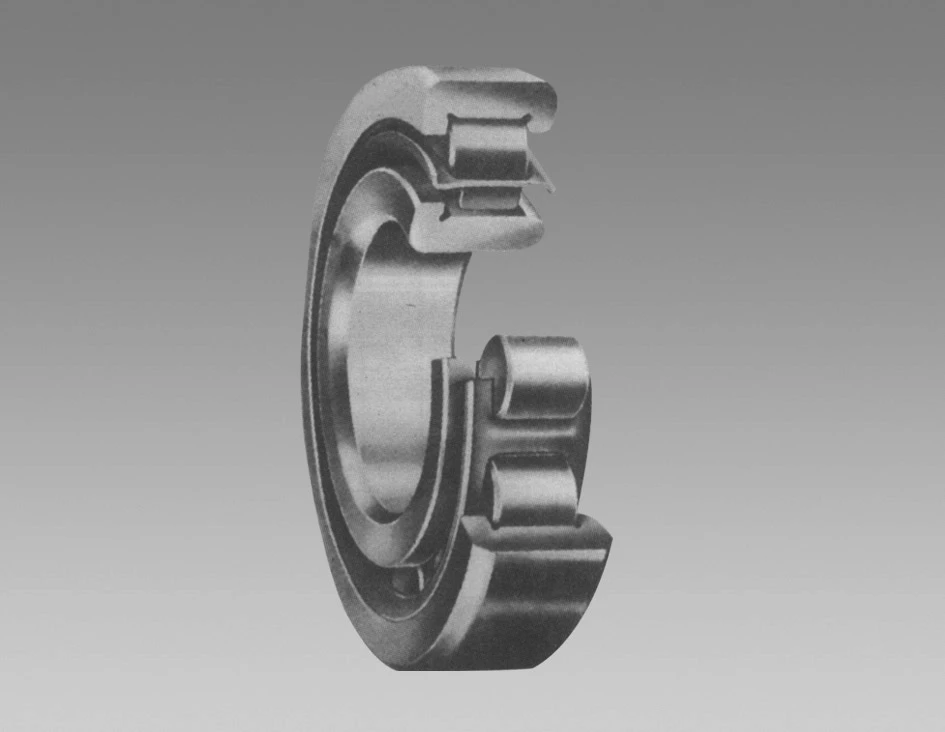

Taper roller bearings consist of an inner ring, an outer ring, tapered rollers, and a cage that holds the rollers in position. The design of these bearings allows for the rollers to make linear contact with both the inner and outer rings, which results in superior load distribution and reduced friction. The tapered shape of the rollers enables the bearing to handle significant axial loads, making them ideal for applications where both radial and axial forces are present.

Key Features of FAG Taper Roller Bearings

1. Robust Construction FAG taper roller bearings are known for their durability and strength. Made from high-quality steel, they can withstand heavy loads and extreme conditions, ensuring longevity.

2. Variety of Sizes FAG offers a comprehensive range of taper roller bearings in various sizes and dimensions, catering to industrial machinery, automotive applications, and more.

3. Precision Engineering FAG employs advanced manufacturing techniques to ensure the precision of their bearings. Tight tolerances and high-quality materials contribute to the performance and reliability of FAG products.

5. Self-Alignment Capabilities FAG taper roller bearings can accommodate slight misalignments between the shaft and housing, which helps to prolong the lifespan of the bearing and the machinery it supports.

fag taper roller bearing

Applications of FAG Taper Roller Bearings

FAG taper roller bearings are used in a wide array of applications across various sectors, including

- Automotive Industry These bearings are commonly found in automobile wheel hubs, transmission systems, and differentials, where they handle both radial and axial loads effectively. - Industrial Machinery FAG taper roller bearings are utilized in heavy machinery such as excavators, conveyor belts, and pumps, ensuring smooth operation under heavy loads. - Aerospace In aircraft engines and landing gear, FAG bearings provide reliable performance in high-stress environments. - Mining and Construction The robust design of FAG taper roller bearings makes them suitable for mining and construction equipment, which typically experiences harsh conditions.

Benefits of Using FAG Taper Roller Bearings

1. Enhanced Performance The precision and quality of FAG taper roller bearings contribute to the overall efficiency of machinery, leading to improved performance and reduced downtime.

2. Cost-Effectiveness Although FAG products may have a higher initial cost compared to lesser-known brands, their durability and reliability translate into lower maintenance costs and prolonged service life.

3. Technical Support FAG, as part of the Schaeffler Group, offers extensive technical support and expertise, assisting customers in selecting the right bearing solutions for their specific applications.

4. Innovation FAG is committed to research and development, consistently innovating to meet the evolving needs of the market. This focus on technology ensures that their taper roller bearings remain at the forefront of the industry.

Conclusion

FAG taper roller bearings are a testament to engineering excellence in the bearing industry. Their unique design, robust construction, and applicability across multiple sectors make them indispensable in modern machinery and automotive applications. By choosing FAG taper roller bearings, businesses can ensure reliable performance, reduced maintenance costs, and enhanced operation efficiency. Whether in heavy industry or delicate machinery, FAG remains a trusted name, delivering high-quality solutions tailored to meet the demands of today's engineering challenges.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025