Aug . 15, 2024 05:42 Back to list

Exploring the Advantages and Applications of Cylindrical Roller Bearings for Enhanced Performance

Understanding Cylindrical Roller Ball Bearings

Cylindrical roller ball bearings are a pivotal component in various mechanical systems, providing essential support and reducing friction between moving parts. These bearings are designed to accommodate heavy radial loads and are particularly favored in applications where space is limited or high operational efficiency is required.

Design and Structure

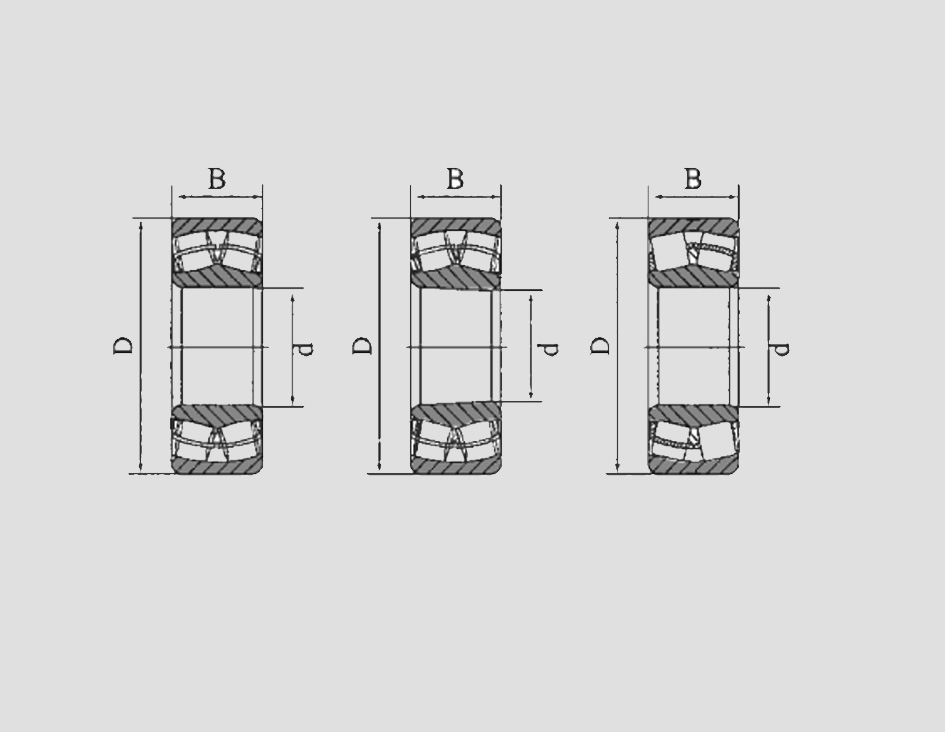

The structure of cylindrical roller bearings is characterized by cylindrical rollers that are arranged within a raceway. This design allows them to withstand heavy radial loads while delivering superior performance. The key components of a cylindrical roller bearing include an inner ring, an outer ring, and a set of cylindrical rollers. The internal geometry of these components is meticulously engineered to facilitate optimal contact between the rollers and the raceways, which minimizes wear and enhances the bearing's lifespan.

One of the most significant advantages of cylindrical roller ball bearings is their ability to accommodate misalignment

. Unlike traditional ball bearings, they can absorb small degrees of axial misalignment without compromising their operational efficiency. This feature makes them ideal for use in machinery that experiences vibration or movement, such as in automotive and industrial applications.Applications

Cylindrical roller ball bearings are used in a wide range of applications across various industries. In the automotive sector, they are often found in the wheel hub assemblies, transmission systems, and electric motors. Their ability to handle high radial loads makes them suitable for use in heavy machinery, such as construction equipment and industrial machinery, where durability and reliability are paramount.

cylindrical roller ball bearing

Furthermore, these bearings play a crucial role in the aerospace industry, where precision and weight efficiency are critical. They are utilized in turbine engines and landing gear systems, providing the necessary support to withstand extreme conditions. In consumer electronics, cylindrical roller bearings can be found in electric motors for appliances, ensuring smooth and efficient operation.

Advantages

The cylindrical roller ball bearing presents several advantages over other bearing types. One of the most notable benefits is their capacity to carry significantly more load than traditional ball bearings. This characteristic is attributed to the increased contact area between the rollers and the raceways. Consequently, they exhibit a higher load-carrying capacity, which contributes to longer service life and reduced maintenance requirements.

Additionally, the low-friction design of cylindrical roller bearings translates into enhanced efficiency. The rolling motion of the rollers generates less heat, reducing energy losses associated with friction. This efficiency is particularly beneficial in large industrial applications where energy savings can have a significant economic impact.

Conclusion

In conclusion, cylindrical roller ball bearings are an essential component in machinery, providing crucial support and promoting operational efficiency. Their unique design accommodates high radial loads while allowing for misalignment, making them versatile in a variety of applications from automotive to aerospace. With their ability to prolong service life and reduce energy consumption, cylindrical roller bearings will continue to be a preferred choice in the engineering and manufacturing sectors. As technology advances and the demand for high-performance components grows, the significance of cylindrical roller ball bearings is sure to expand, shaping the future of mechanical systems worldwide.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025