Dec . 02, 2024 07:30 Back to list

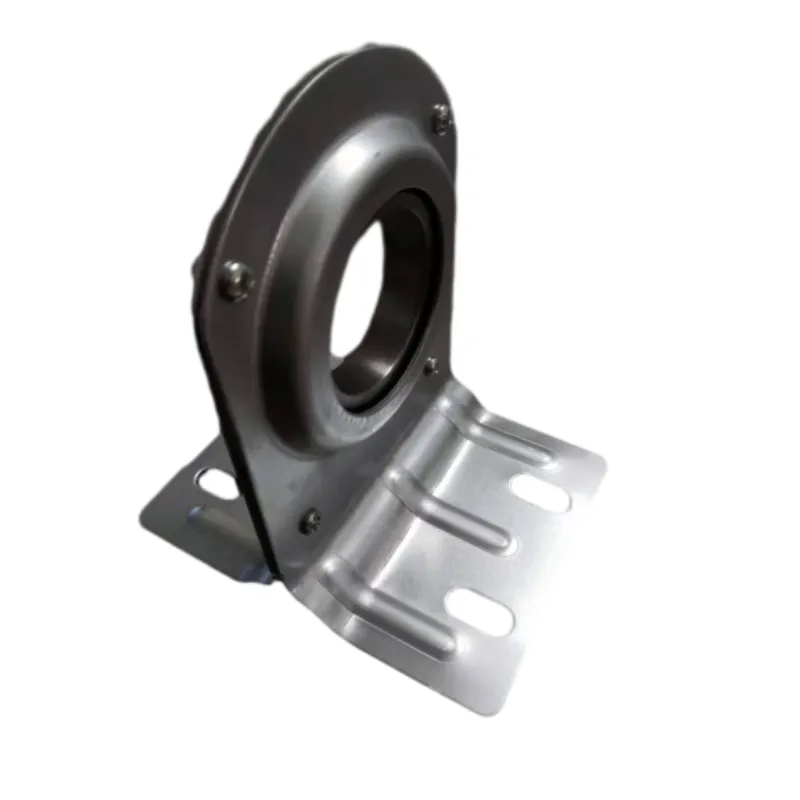

drac bearing

Understanding DRAC Bearings A Comprehensive Guide

In the world of mechanical engineering and machinery, bearings play a crucial role in ensuring smooth operation and longevity of moving parts. Among various types of bearings, DRAC bearings have gained considerable attention for their unique features and performance capabilities. This article aims to delve into the intricacies of DRAC bearings, including their design, applications, benefits, and maintenance.

What are DRAC Bearings?

DRAC bearings, short for Dual Row Angular Contact bearings, are specialized components designed to handle both radial and axial loads. Unlike standard bearings that typically manage one type of load at a time, DRAC bearings are engineered to accommodate complex load scenarios. Their design features two rows of rolling elements, allowing them to support forces acting in both directions efficiently. This dual-action capability makes them suitable for high-performance applications, where precision and reliability are paramount.

Design Features

The design of DRAC bearings is characterized by several notable features. Firstly, the angular contact architecture allows for enhanced load-carrying capacity and better rigidity. This structure enables the bearings to be more compact without compromising their performance under stress. Additionally, DRAC bearings are often made of high-quality materials, such as stainless steel or ceramic, which increase their durability and resistance to corrosion. The precision machining of the bearing races ensures smooth rotational motion, reducing friction and wear.

Applications of DRAC Bearings

Due to their exceptional performance traits, DRAC bearings are utilized in a plethora of applications across various industries. One prominent example can be found in the automotive industry, where these bearings are employed in wheel hub assemblies, providing stability, efficiency, and safety. In the aerospace sector, they are used in landing gear and other critical components where reliability is non-negotiable.

Furthermore, DRAC bearings find their place in high-speed machinery, electric motors, and industrial equipment. Their ability to handle both radial and axial loads makes them ideal for equipment subjected to dynamic forces, such as pumps and compressors. The versatility of these bearings enables engineers and designers to integrate them into new innovations seamlessly, ensuring optimal performance and longevity.

drac bearing

Benefits of DRAC Bearings

The advantages of using DRAC bearings are manifold. Most notably, their design allows for greater load capacity, which reduces the risk of failure under heavy operational stress. This increased reliability can significantly decrease maintenance costs and downtime associated with equipment breakdowns. Moreover, the reduced friction associated with DRAC bearings translates into enhanced energy efficiency, making them an environmentally friendly choice.

Another key benefit is their adaptability. DRAC bearings can be configured to suit specific applications, allowing for customization according to load requirements and operational conditions. This flexibility enables manufacturers to optimize machinery design, ultimately leading to better performance and extended product lifespans.

Maintenance and Care

While DRAC bearings are engineered for durability, proper maintenance is essential to maximize their lifespan. Regular inspection for signs of wear, such as discoloration or pitting, is crucial. Additionally, ensuring proper lubrication is vital. Both over-lubrication and under-lubrication can lead to bearing failure, affecting the overall operation of the machinery.

Contamination is another factor to consider; dirt, dust, and other particles can compromise the performance of bearings. Implementing effective sealing solutions can help prevent unwanted contaminants from entering the bearing system. Finally, maintaining the correct operating environment, including temperature and humidity control, is instrumental in ensuring the bearings perform optimally for an extended period.

Conclusion

In summary, DRAC bearings stand out as a formidable choice for various industrial applications, thanks to their innovative design and ability to handle complex load scenarios. With their ability to provide enhanced performance, durability, and reliability, they are indispensable in achieving efficient machinery operation. Proper maintenance is key to unlocking the full potential of these advanced bearing systems. As technology continues to evolve, the versatility and functionality of DRAC bearings are likely to play an even more significant role in the future of engineering and manufacturing. Whether in the automotive, aerospace, or industrial sectors, DRAC bearings represent a smart investment for any organization looking to enhance its operational capabilities.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025